lbursell

Well-known member

All right, gentlemen,

I guess it’s finally time for me to step up to the plate. What we have here is a long neglected 1982 model 1652 MonArk with a 25 horse motor by Evinrude, also 1982 model. The boat has been sitting beneath an RV carport for at least 8 years. Right off the bat, here, before anything else – Thanks to Jim for creating a fantastic site for ordinary fishermen and boaters to share knowledge and experiences in an enjoyable, supportive environment. This is the only forum I’ve ever joined or even been interested in joining. I’ve been hovering and lurking here, with the occasional posted comment since last summer, when I stumbled across a couple of YouTube postings with links to TinBoats. I’ve been feeding my TinBoat addiction with almost daily injections of cruising the threads, getting ideas and inspiration from the builds found here to apply to my own soon-to-be dream boat/fishing machine. Fair warning – I am completely new to this boat remodeling craft so I will unashamedly beg, borrow and definitely steal ideas and techniques from here to use in my own build. Plans at the moment include using vinyl decking boards, instead of wood, for trailer bunks; using HydroTurf mats, instead of carpet, for all of my horizontal deck surfaces and trying out one of Water Snake brand trolling motors from Australia. I have some ideas that may be a little off the wall (I prefer “out of the box”) about how to proceed with parts of my build, so I will welcome any and all comments, questions, encouragement or criticism that will help me in getting a better boat out of the process.

So, here’s the boat. We bought it back in the late 1990’s primarily for fishing in the back bays around Corpus Christi and Port Aransas, with the very occasional trip into fresh water. We moved to North Texas in 2000. Somehow, going fishing took a back burner position to other priorities and the boat became the location to stack scrap lumber and other materials left over from various projects around the house. Looking back, it seems like there were a LOT of projects back then, so there is a lot of just plain, ol’ junk to get out of the way.

How long does something have to sit to sink this deep into the soil?

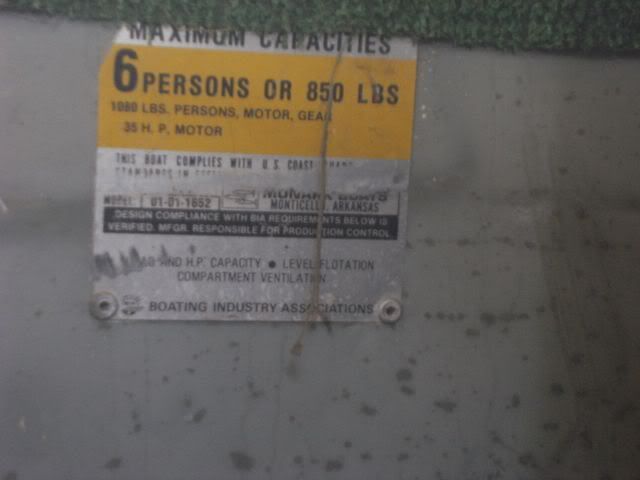

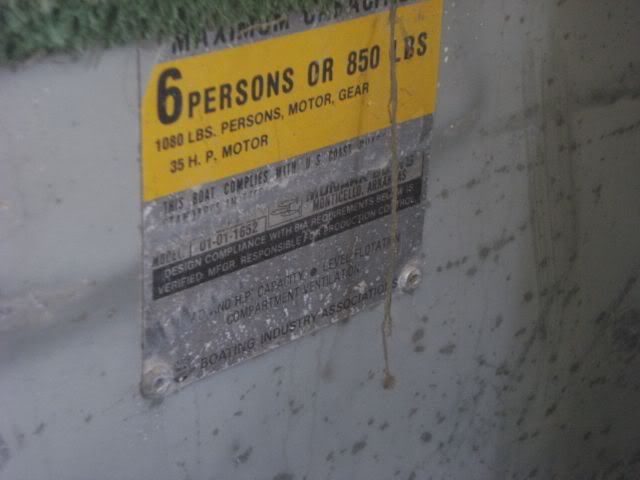

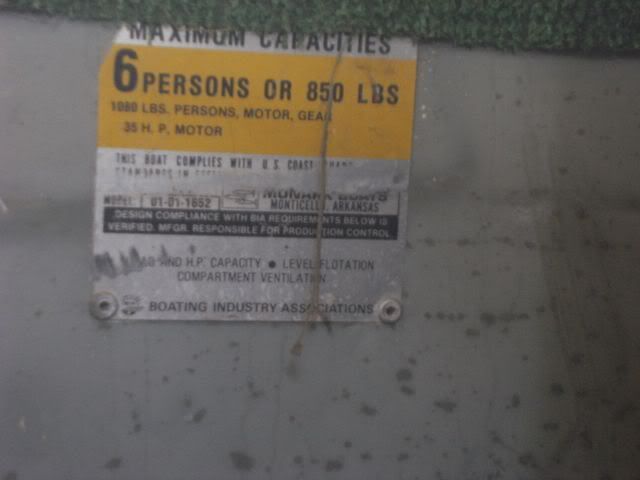

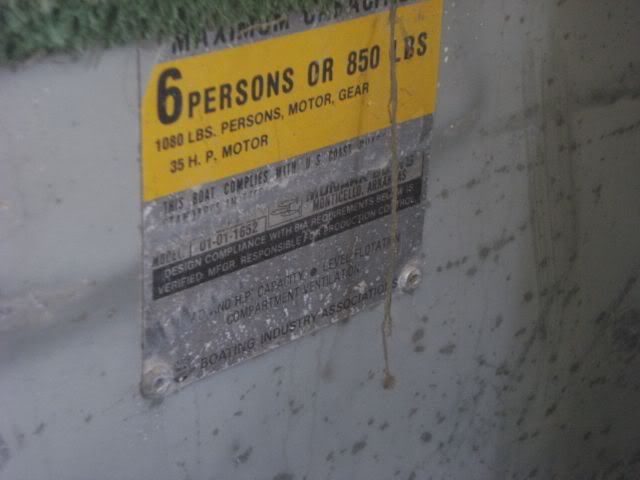

A couple of pics of the “VIN” plate just to show how much there is to work with here.

All of the junk is out and either hauled off or stashed elsewhere. I have to admit (while hanging my head ), this was a great opportunity to get rid of an eyesore that had grown in the back yard. Pic from the front of the boat.

), this was a great opportunity to get rid of an eyesore that had grown in the back yard. Pic from the front of the boat.

Middle bench towards the stern. Gotta love the green astroturf-colored carpet. I don’t think they made outdoor carpet in any other color back then.

And the back.

From the stern towards the bow.

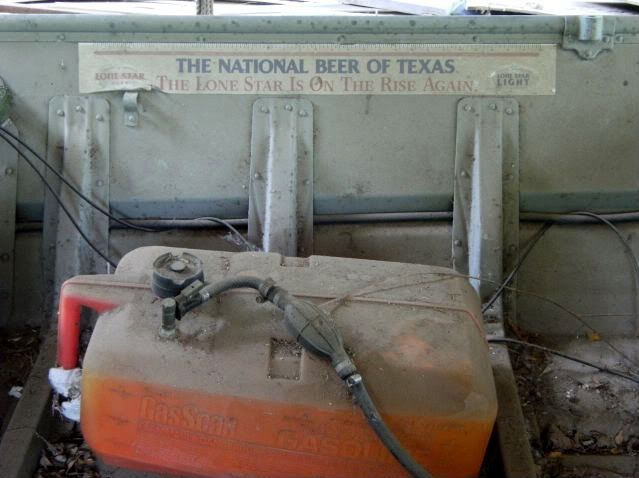

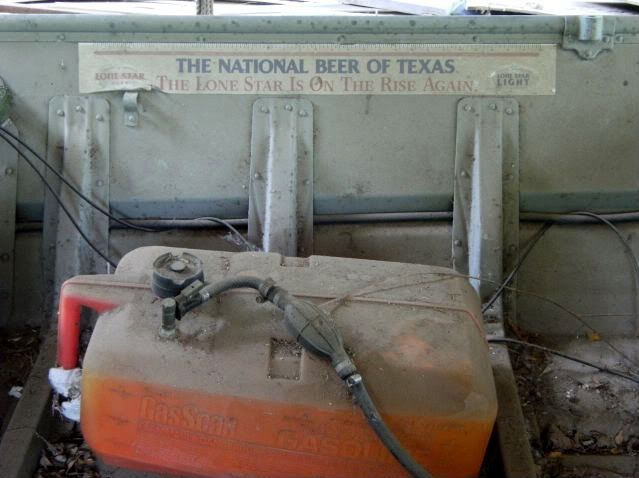

I hope “is on the rise again” applies to the boat.

The floor between the benches.

The front deck.

The previous owner had put actual carpet padding beneath the green stuff on the front deck. It was easy on feet and kept that big aluminum sheet from sounding like a big kettle drum when you dropped something on it. I’m not intending to go that route.

Weapons of choice for removing carpet and glue. The carpet padding took very little effort to get up.

And the green carpet came off like peeling an orange. Just a few quick tugs and it peeled right up.

The carpet glue, however, was another story entirely. It had bonded to the aluminum extremely well (can’t be mad, ‘cause that is what it’s supposed to do) and was a bugger to get up.

In the end, there were three different types of glue applied to the boat. The white stuff came away fairly easily. The two types of darker, gray stuff felt at times like I was chipping away at marble. I don’t know if the PO did it in three different projects, or, if he would have been like me, and just worked with what he had around the house at the time.

Anyway, getting out the carpet and the majority of the carpet glue took the better part of a week, working one or two hours a day. I decided to refurbish the trailer before getting too deep into the boat, so digging out the trailer became the next step.

Almost like an archeological dig. Somewhere, Indiana Jones is hanging from a winch and cable over a snake pit. I did kill two copperheads that I disturbed during this phase of operations. Pretty snakes, but I didn’t want them that close to the house.

Front end up and out.

Is the back end sunk that deep or is the tire flat? Both.

Step 1: Jack up the trailer and boat on both sides.

Step 2: Place cinder blocks, spare tires or whatever works for you beneath the boat with landscape timbers laid across to support the boat.

Step 3: Lower the trailer, leaving the boat supported in mid-air. I was not happy with the single landscaping timber, so I repeated the entire process and doubled up on the landscape timbers.

Rotate the trailer guide-ons back and then down so they can clear the landscape timbers when the trailer is pulled out.

The rear of the boat is supported on two sides with cinderblocks and landscape timbers and at the stern with more cinderblocks. The guide-ons were released and allowed to drag behind the trailer until it was clear. I’m replacing the lights, anyway.

The front end of the boat is suspended from the roof of the RV shed. Move a few bricks out of the way and the trailer is ready to pull out.

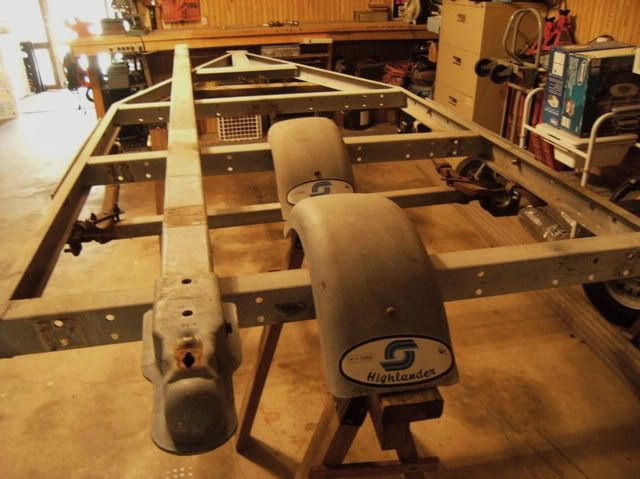

I guess I forgot to take pictures of the trailer while it was pulled out. This pic just shows how little room there is to spare once I got it into the garage. But, there will be plenty of trailer pictures in the next upload which will consist mostly of the trailer tear down and preparation for paint. Also, there will be blood.

I guess it’s finally time for me to step up to the plate. What we have here is a long neglected 1982 model 1652 MonArk with a 25 horse motor by Evinrude, also 1982 model. The boat has been sitting beneath an RV carport for at least 8 years. Right off the bat, here, before anything else – Thanks to Jim for creating a fantastic site for ordinary fishermen and boaters to share knowledge and experiences in an enjoyable, supportive environment. This is the only forum I’ve ever joined or even been interested in joining. I’ve been hovering and lurking here, with the occasional posted comment since last summer, when I stumbled across a couple of YouTube postings with links to TinBoats. I’ve been feeding my TinBoat addiction with almost daily injections of cruising the threads, getting ideas and inspiration from the builds found here to apply to my own soon-to-be dream boat/fishing machine. Fair warning – I am completely new to this boat remodeling craft so I will unashamedly beg, borrow and definitely steal ideas and techniques from here to use in my own build. Plans at the moment include using vinyl decking boards, instead of wood, for trailer bunks; using HydroTurf mats, instead of carpet, for all of my horizontal deck surfaces and trying out one of Water Snake brand trolling motors from Australia. I have some ideas that may be a little off the wall (I prefer “out of the box”) about how to proceed with parts of my build, so I will welcome any and all comments, questions, encouragement or criticism that will help me in getting a better boat out of the process.

So, here’s the boat. We bought it back in the late 1990’s primarily for fishing in the back bays around Corpus Christi and Port Aransas, with the very occasional trip into fresh water. We moved to North Texas in 2000. Somehow, going fishing took a back burner position to other priorities and the boat became the location to stack scrap lumber and other materials left over from various projects around the house. Looking back, it seems like there were a LOT of projects back then, so there is a lot of just plain, ol’ junk to get out of the way.

How long does something have to sit to sink this deep into the soil?

A couple of pics of the “VIN” plate just to show how much there is to work with here.

All of the junk is out and either hauled off or stashed elsewhere. I have to admit (while hanging my head

Middle bench towards the stern. Gotta love the green astroturf-colored carpet. I don’t think they made outdoor carpet in any other color back then.

And the back.

From the stern towards the bow.

I hope “is on the rise again” applies to the boat.

The floor between the benches.

The front deck.

The previous owner had put actual carpet padding beneath the green stuff on the front deck. It was easy on feet and kept that big aluminum sheet from sounding like a big kettle drum when you dropped something on it. I’m not intending to go that route.

Weapons of choice for removing carpet and glue. The carpet padding took very little effort to get up.

And the green carpet came off like peeling an orange. Just a few quick tugs and it peeled right up.

The carpet glue, however, was another story entirely. It had bonded to the aluminum extremely well (can’t be mad, ‘cause that is what it’s supposed to do) and was a bugger to get up.

In the end, there were three different types of glue applied to the boat. The white stuff came away fairly easily. The two types of darker, gray stuff felt at times like I was chipping away at marble. I don’t know if the PO did it in three different projects, or, if he would have been like me, and just worked with what he had around the house at the time.

Anyway, getting out the carpet and the majority of the carpet glue took the better part of a week, working one or two hours a day. I decided to refurbish the trailer before getting too deep into the boat, so digging out the trailer became the next step.

Almost like an archeological dig. Somewhere, Indiana Jones is hanging from a winch and cable over a snake pit. I did kill two copperheads that I disturbed during this phase of operations. Pretty snakes, but I didn’t want them that close to the house.

Front end up and out.

Is the back end sunk that deep or is the tire flat? Both.

Step 1: Jack up the trailer and boat on both sides.

Step 2: Place cinder blocks, spare tires or whatever works for you beneath the boat with landscape timbers laid across to support the boat.

Step 3: Lower the trailer, leaving the boat supported in mid-air. I was not happy with the single landscaping timber, so I repeated the entire process and doubled up on the landscape timbers.

Rotate the trailer guide-ons back and then down so they can clear the landscape timbers when the trailer is pulled out.

The rear of the boat is supported on two sides with cinderblocks and landscape timbers and at the stern with more cinderblocks. The guide-ons were released and allowed to drag behind the trailer until it was clear. I’m replacing the lights, anyway.

The front end of the boat is suspended from the roof of the RV shed. Move a few bricks out of the way and the trailer is ready to pull out.

I guess I forgot to take pictures of the trailer while it was pulled out. This pic just shows how little room there is to spare once I got it into the garage. But, there will be plenty of trailer pictures in the next upload which will consist mostly of the trailer tear down and preparation for paint. Also, there will be blood.