Well, I finished stripping it down today, for the most part. It still needs a major cleanup, and the transom stuff needs work (I am not sure what the previous owner did - something like 6 holes with wood screws going into the aluminum to mount a transducer - not to mention the mess of bilge and livewell pumps)

Here is the picture of the bow after I finished stripping it.

Ignore the pile of rusty fasteners there. If you remember, there was that hatch that opened up to the hull, and for some reason, every time I pulled a fastener out, it got tossed into that hatch. Now, towards the bottom of the picture, you can see a bulkhead that I had no clue existed, until pulling out the deck. Seems the boat had a short casting deck originally, that was then replaced by the previous owner. Also, that lip in the bow, and the two pieces of aluminum, that were angled with the hull to provide a level mounting surface were a dead giveaway as to the original deck in the bow. The deck mate screws holding the 2 x 8s underneath the deck were a giveaway as to the fact that it had been indeed replaced once.

Here is a shot of the stern, with the deck removed. The stern deck extended forward to the dark spot on the carpet. That is too far forward to sit and reach the tiller, and I don't relish the idea of being way up on a pedestal to operate it. My new deck will extend to those seat pods, but no further.

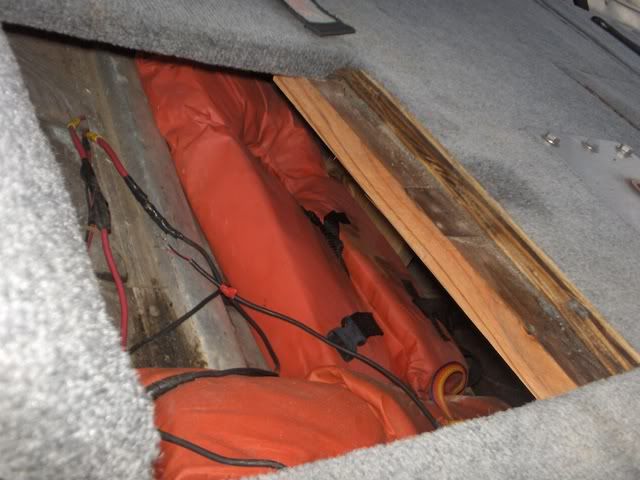

Now I get to the bottom deck. I am positive this was factory, as it used marine grade plywood, instead of pressure treated (which has NO place in an aluminum boat) and the fact that stainless fasteners were used, not a combination of trim and cabinet screws, and deck mate screws. Not to mention the fact that it was much more rotted - it had obviously been in there much longer than the rest. Also, there is some saturated flotation foam under there.

All the rest of the carpet had been taken off with the deck, plus it was stapled, and not glued, but on the side panels, it was glued. I have not seen a more durable glue in my life. It took me an hour and 15 minutes to remove the carpet from the two sides. Not to mention, it is something like 2 pieces, 7 feet by 2 feet. Notice that 2 1/2 foot long screwdriver (prybar) on the bottom? I had to use that as a chisel to dig up the glue. Seeing that it was an internal panel, I wasn't as worried about it. If it were on the hull, I don't know what I would do, as that could punch a hole in the hull, and the carpet wasn't coming off any other way.

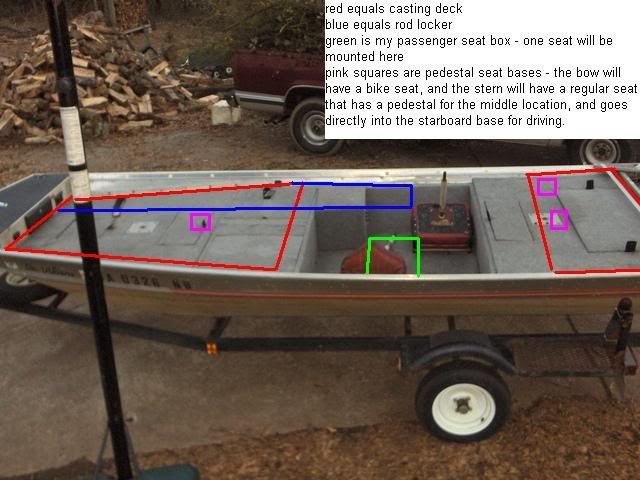

I have a pretty good plan of the layout when I put her back together. The rest of my week is pretty busy, but I will try to have it cleaned out by the end of this week. Then, if all goes to plan, I will try to start, if not finish, any work the trailer needs next week.

Hopefully, in the next 3 weeks, I will start framing. We have a few hundred feet of aluminum stock in the shop here, that I won't have to repay dad for until later, so that will allow me an early start. But, I will have to wait until the buyer picks up the Grumman for me to have a bit of cash to start with everything else. I am searching for a deal on some 1/8 inch aluminum sheet, that isn't diamond plate, in the right alloy. The search is somewhat futile. Luckily though, aside from the aluminum sheet, and buying the motor from my dad, I have most of the large expenses covered - boat, trailer, trolling motor, kicker motor, batteries etc. It is just left to the millions of small expenses that ad up to be killer. But, for me, as my money comes in small amounts over time, they are easier, as I can spread the purchases out with my income.