baseball_guy_99

Well-known member

Hello guys of the Jon Boat world! My dad and I recently purchased this jon boat, trailer, and 1989 40hp Evinrude for $300.

The motor was not running when we bought it, but a new fuel pump cap and a carb clean and she runs like a champ.

The boat itself is in a little bit rough condition (it was used on the Ohio River for juggin). We had some of the rivets welded and one spot on the front where it had a small hole knocked in it. We took out the old transom because it was completly rotted and replaced it with sealed plywood. On the outside of the transom we used 3/4" rubber mine belt. We replaced all the old aluminum bolts with stainless steel bolts, nuts, and lock washers. For added precaution we put rubber washers around the head of the bolts.

The trailer was in fairly good conditon. Had to replace the tires and repaint the rims. Added a winch to the front because all they had was a rope. Added a jack stand as well. One of the welds on the right side brace was broke but we welded it back in place.

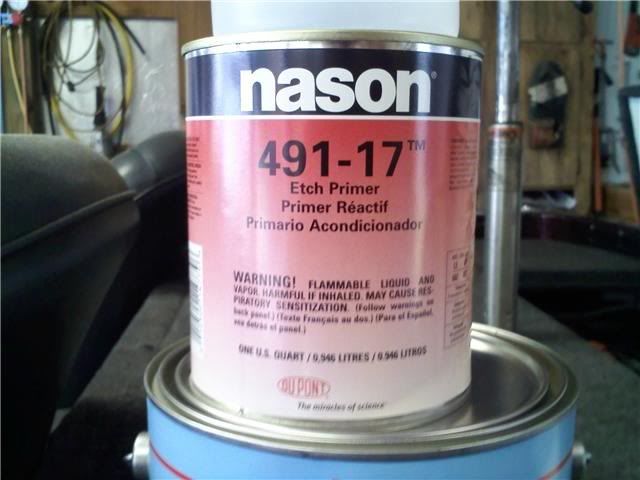

I used a scotch brite pad to clean the bottom of the boat (it had years of scum caked on it). I then used a heat gun and a scraper to get off all the old decals and stickers. I'm in the process of sanding it down to be repainted.

I plan to removed the front bench seat to have a more open floor plan as I will be using this boat for mainly duck hunting. I'm going to put down a floor using stuff called AlucaBond. A guy in my area is a dealer and he says this stuff works wonders in Jon Boats. (If anyone has used this please leave some feedback.). Then I'm going to carpet over it. I'm not sure if I want to cover the sidewalls and carpet them as well (I guess it just comes down to aesthetics).

Alright enough of me rambling...here are some pics.

This is right after we got it home.

Feel free to leave comments and or suggestions. I'm still in the designing phase so I'm open to anything.

The motor was not running when we bought it, but a new fuel pump cap and a carb clean and she runs like a champ.

The boat itself is in a little bit rough condition (it was used on the Ohio River for juggin). We had some of the rivets welded and one spot on the front where it had a small hole knocked in it. We took out the old transom because it was completly rotted and replaced it with sealed plywood. On the outside of the transom we used 3/4" rubber mine belt. We replaced all the old aluminum bolts with stainless steel bolts, nuts, and lock washers. For added precaution we put rubber washers around the head of the bolts.

The trailer was in fairly good conditon. Had to replace the tires and repaint the rims. Added a winch to the front because all they had was a rope. Added a jack stand as well. One of the welds on the right side brace was broke but we welded it back in place.

I used a scotch brite pad to clean the bottom of the boat (it had years of scum caked on it). I then used a heat gun and a scraper to get off all the old decals and stickers. I'm in the process of sanding it down to be repainted.

I plan to removed the front bench seat to have a more open floor plan as I will be using this boat for mainly duck hunting. I'm going to put down a floor using stuff called AlucaBond. A guy in my area is a dealer and he says this stuff works wonders in Jon Boats. (If anyone has used this please leave some feedback.). Then I'm going to carpet over it. I'm not sure if I want to cover the sidewalls and carpet them as well (I guess it just comes down to aesthetics).

Alright enough of me rambling...here are some pics.

This is right after we got it home.

Feel free to leave comments and or suggestions. I'm still in the designing phase so I'm open to anything.