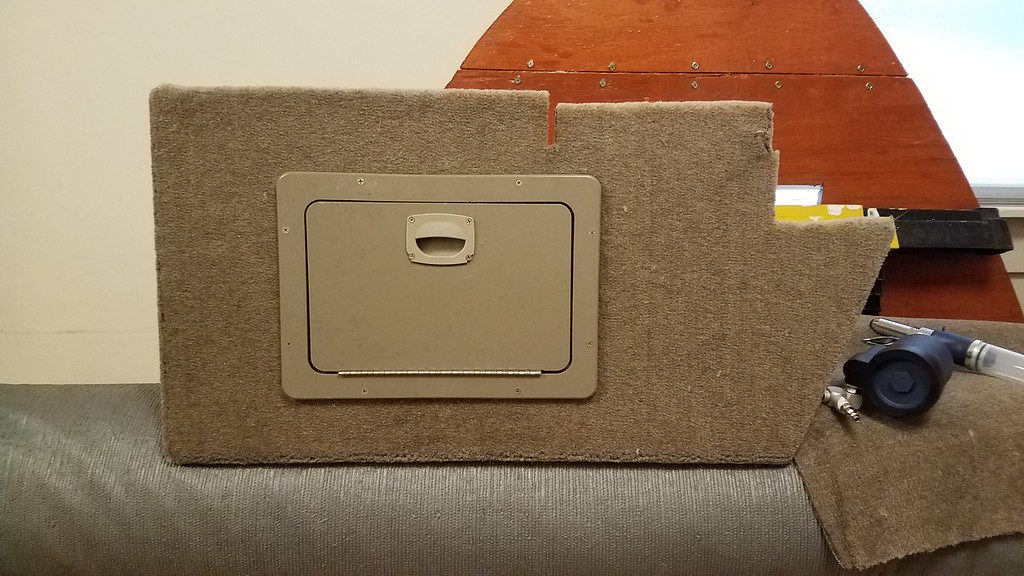

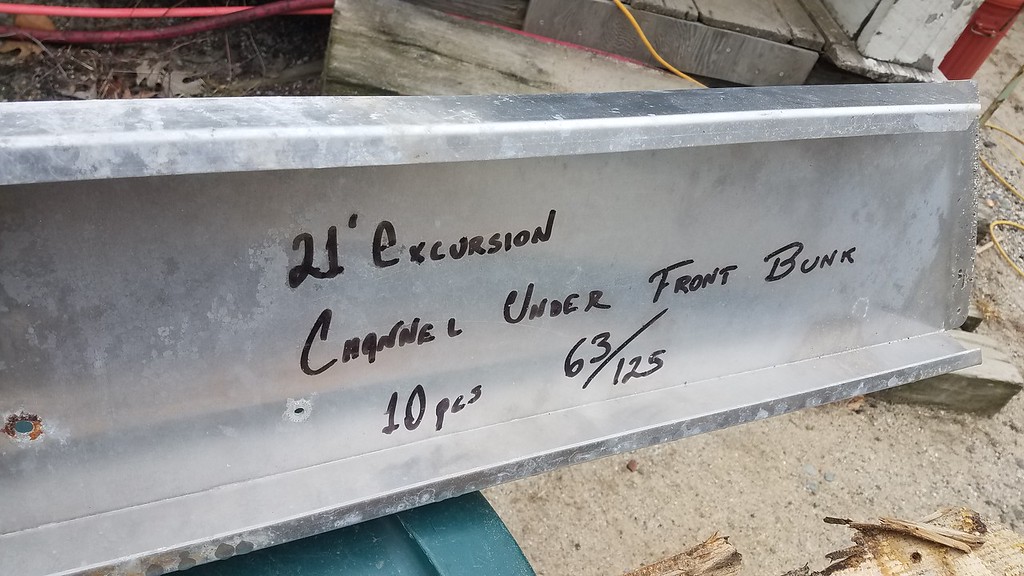

I finally have a fairly large boat project that is worthy of starting a thread here for. I'm replacing some carpet and by default a bunch of the wood floor in my Sylvan 2100 Profish. I worked on it pretty much all weekend, got the demo and everything stripped down, and all the wood cut. I have 18 pieces to re-carpet, including some aluminum lids over my livewells. Any advice to make that go well is welcomed. Some pieces like the bulkhead (carpeted pieces in the bow beneath the walkthrough windshield) are going to be tricky with the angles.

This is a brain dead project, since all I am doing is replacing exactly what is there, and it's still a serious handful. Makes me really respect what you guys that customize so much deal with. Anyway, not very interesting but everyone loves pictures, so...

All the carpet needs to be replaced, but it's the front and rear casting decks that are really tired looking:

Welcoming any suggestions as to how to fix the corrosion around the recessed cleats and all the snap fittings for the cover. It's eaten the paint away pretty good. Aluminum still seems solid for now but I need to address it. Amazed the factory wouldn't isolate these cleats.

So after a full weekend of work, both casting decks are out, bulkhead, walkthrough steps etc. All the aluminum lids, hinges and angles are stripped and all the wood is cut. I'm ready to start sealing with old timers. How many coats of old timers is suggested?

How horrible is the old timers formula to breathe? I have no garage, and the next two weeks here in NH are looking cold, wet and nasty. I'm wondering if I can bring the pieces into my work, where we have a big warehouse, but it's attached to the offices and if it's a real potent mixture it might not work. I can't wait until it gets nice outside, spring trolling in Northern New England is only a few weeks away.

This is a brain dead project, since all I am doing is replacing exactly what is there, and it's still a serious handful. Makes me really respect what you guys that customize so much deal with. Anyway, not very interesting but everyone loves pictures, so...

All the carpet needs to be replaced, but it's the front and rear casting decks that are really tired looking:

Welcoming any suggestions as to how to fix the corrosion around the recessed cleats and all the snap fittings for the cover. It's eaten the paint away pretty good. Aluminum still seems solid for now but I need to address it. Amazed the factory wouldn't isolate these cleats.

So after a full weekend of work, both casting decks are out, bulkhead, walkthrough steps etc. All the aluminum lids, hinges and angles are stripped and all the wood is cut. I'm ready to start sealing with old timers. How many coats of old timers is suggested?

How horrible is the old timers formula to breathe? I have no garage, and the next two weeks here in NH are looking cold, wet and nasty. I'm wondering if I can bring the pieces into my work, where we have a big warehouse, but it's attached to the offices and if it's a real potent mixture it might not work. I can't wait until it gets nice outside, spring trolling in Northern New England is only a few weeks away.