Finally I get to start my v hull mod!!! I got a rockin little boat I don't know the make or model since its titled with a flz prefix (homemade). I was hoping maybe you guys can give me an idea on this one? The title says 1960 but I doubt that is realistic. The boat measures exactly 13' 8" long and 5 ft wide at the stern the previous owner said it would draw 4 inch of water. I got the boat, life jacket, oars, clamp on lights, rebuilt trailer with fresh lights and wiring new bunks etc. running 8hp Johnson, 6 gal fuel tank with line, one seat, military compass (cool freebie!!) a few rods holders and a bunch of 2x4, 2x8 plasti-wood planks all for $500. The previous owner stripped the boat epoxied it and clear coated it he also cut the bench seats out. The clear coat is peeling but that is ok because I am making this boat MY boat and redoing it all.

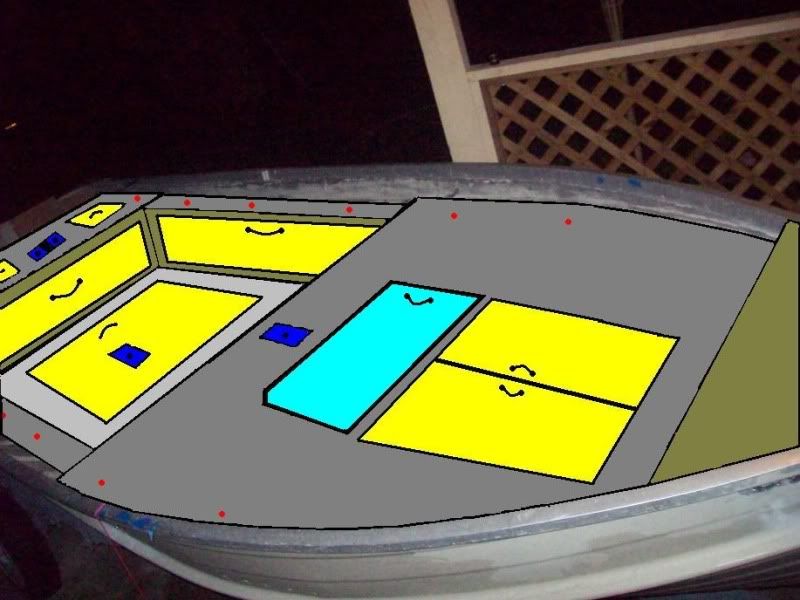

I plan to add a casting deck, bow mounted foot controlled trolling motor, fish/depth finder, polling platform, storage and live well and all the necessary items to keep this thing safe and floating. My two main goals for this boat is keeping light and functional.

To start off the project I will build the interior framing, transom. Today I purchased 40 ft of 1-1/2x1/8 aluminum angle. The desk will be 3/8 plywood coated in fiberglass resin with fiber glass mating to add some strength. Later I may change it out for aluminum but I would like to keep the build cost reasonable and I would prefer to have other luxuries at this time.

Before I get crazy cutting into this beautiful aluminum angle I noticed while lurking on this site for the past two weeks some people use self tapers, rivets, even 2x2 wood framing with braces and wood screws. So I have some questions. I don't see any welding and am curious why? Is it the inability to weld or cost to higher a welder? Structurally wouldn't a weld be ideal assuming the design of the frame be properly triangulated and boxed? I understand a rivet would allow some min flex and movement and assume that this the goal? Hence is the reason why I see this practiced in the majority of the builds I have reviewed. I do not have any experience in riveting anything I understand the concept as it is quite simple. I can mig and tig weld so that is naturally my preferred choice when working with metal. Opinions?

Pics of boat coming asap!! As promissed..

Decided to use rivets to build the framing. I should get a good amount of work done to this thing over the weekend!!

I plan to add a casting deck, bow mounted foot controlled trolling motor, fish/depth finder, polling platform, storage and live well and all the necessary items to keep this thing safe and floating. My two main goals for this boat is keeping light and functional.

To start off the project I will build the interior framing, transom. Today I purchased 40 ft of 1-1/2x1/8 aluminum angle. The desk will be 3/8 plywood coated in fiberglass resin with fiber glass mating to add some strength. Later I may change it out for aluminum but I would like to keep the build cost reasonable and I would prefer to have other luxuries at this time.

Before I get crazy cutting into this beautiful aluminum angle I noticed while lurking on this site for the past two weeks some people use self tapers, rivets, even 2x2 wood framing with braces and wood screws. So I have some questions. I don't see any welding and am curious why? Is it the inability to weld or cost to higher a welder? Structurally wouldn't a weld be ideal assuming the design of the frame be properly triangulated and boxed? I understand a rivet would allow some min flex and movement and assume that this the goal? Hence is the reason why I see this practiced in the majority of the builds I have reviewed. I do not have any experience in riveting anything I understand the concept as it is quite simple. I can mig and tig weld so that is naturally my preferred choice when working with metal. Opinions?

Pics of boat coming asap!! As promissed..

Decided to use rivets to build the framing. I should get a good amount of work done to this thing over the weekend!!