Lots of progress, the wife & kids were out of town visiting her parents this week.

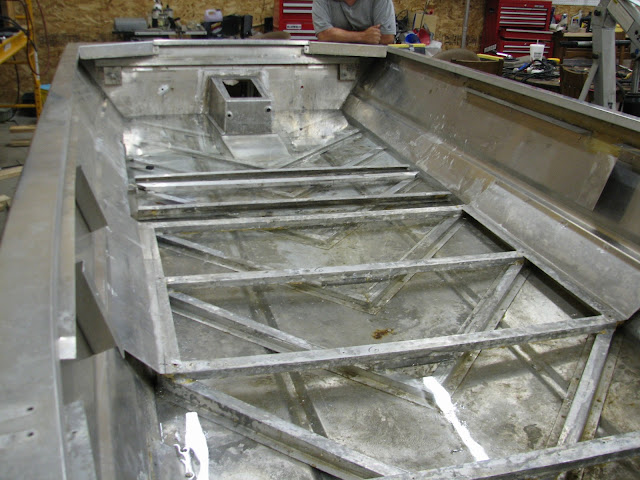

Remember this keel skeg that ran down the center of the boat? In this OLD picture you can see it:

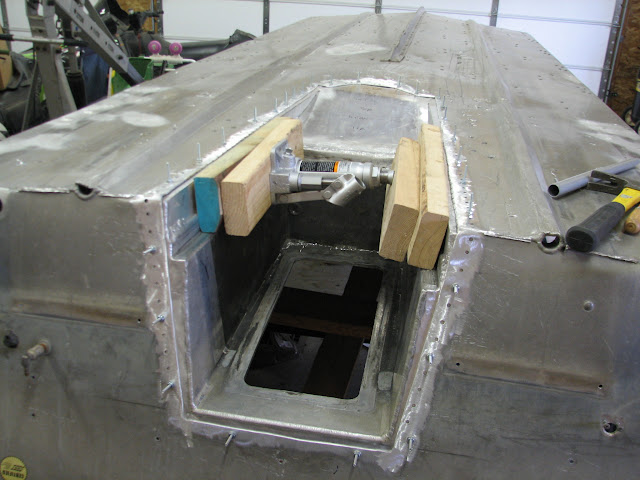

I cut it off, and welded up the rivet holes and seam... my logic is, if I need it for handling, I can add it back. If I need it for hull protection, I can add a UHMW piece. But when you hit a rock with that skeg the boat just stops because that skeg digs into the rock like a knife. And I need to sliiiiide over things, handling is 2nd.. I also roughed up the entire bottom of the hull and lower sides with a sander in preparation for "the next step"

What is the next step? Well I was debating putting UHMW on the bottom, I still might someday, but for now, since the bottom of my boat has rivets and is so beat up, I decided to have it coated with Hardline:

https://rhinoliningsindustrial.com/products/polyurethane_and_polyurea/hardline/22/32

I came to this decision based on Rhino's Hardline info page:

https://rhinoliningsindustrial.com/case_studies/impact_-_abrasion/202

Which contained this "application note" for aluminum boat's:

https://rhinoliningsindustrial.com/gfGy6S44anlz/1272558518Aluminum Jet Boat Hull.pdf

I contacted the author of that note, who has this on his Predator in Alaska and he swears by it, so I decided I'd give it a try. If it doesn't work as I hope, I can always put UHMW on top of it, and the liner should at least make things smoother for the liner to mount to.

So I dropped it off at Zeibart in Ottowa, IL.. here it is 8 hours and $916 later ($100 for self etching primer, and about $7 per sq foot).

Check out how it

ALMOST hides the rivets:

They claimed they'd apply it 1/8" thick... I wanted 1/4" they said they'd try but it didn't sound like something they could control that accurately. I had them not do any "roughing up", tried to keep it slick/smooth as possible.

I have to wait 24 hours before I can flip it/use it...

My initial impression of the liner is that it is awesome stuff:

- When wet, it is definately slicker than the aluminum.

- It really smooths out the bottom in terms of previous damage, scratches, dents, and rivets

- Looks much nicer than bare aluminum

- If it stays stuck to the boat and is as tough as they claim it is, this really ought to help protect things.

- I noticed if I "slap" the coated parts with my hand they seem more solid than the uncoated parts... the aluminum flexes less.

So, here's to HOPING this product does what it claims. I'm a little leary, the product could be overstating it's ruggedness, the application might not have been done quite right, who knows? Lots of things could be wrong. But I like to try stuff out for myself, so here we are.

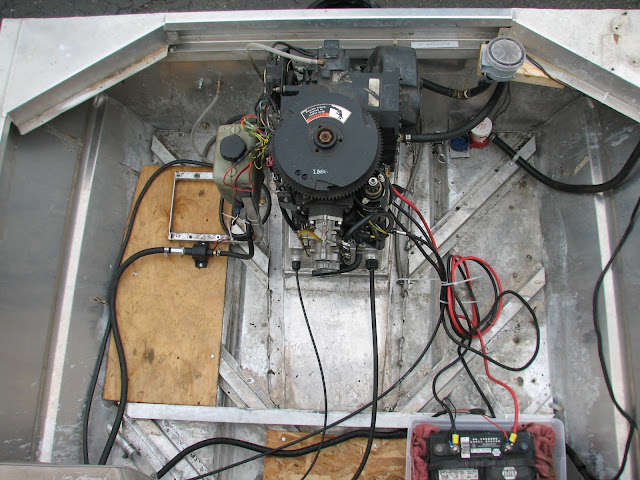

This weekend, I'm going to clean the carbs and start putting it back together. Eventually I'll repaint the back of the transom and upper sides, I'm thinking a camo theme would look cool to contrast the black sides.