mmf

Well-known member

Lookin good Jerry! Glad you missed the hurricane too! Irene winds blew steady here all day today.

We had higher tides due to wind, but those pics from the east coast look scarry! :shock:mmf said:Lookin good Jerry! Glad you missed the hurricane too! Irene winds blew steady here all day today.

Mojo, the tubing on the side is 1x2 "C" shaped which makes it bendable. Starting at the bow, I justMojo^ said:On the 2" square tubing you used to attach the framing to the hull; did you simply clamp it to the hull and it formed to the contour or did you have to form it separately in a jig of some sort?

Don, The 1/16" DP is more flexible and requires more bracing than the 1/8 DP, but it is also lighter.olbrazosDon said:Jerry, I have been watching your progression of the modification of your boat. By the way very good looking, well thought out. You posted that you ordered 1/16" DP sheets of aluminum for decking. I am wondering if the 1/16" plate is thick enough. I have an Alumacraft 1448 that I want to put a front deck on and I was concerned with the thickness of plate that I would use. Your comments would bee appreaciated.

Busbey said:i agree about getting more paint on the surface. also, with the paint suggested, would i use a clear coat? is there any wet sanding involved?

what i want to see is an up close shot of the texture it leaves though. kinda like this.

I forgot to mention that lacquer thinner is a good cleaner too and probably cheaper than alcohol.Busbey said:good deal. going to get going on this soon. all i need is a day of sanding on the boat. next morning, clean with alcohol and start rolling the paint. how much time should i wait between coats? i may need to get up early in the morning to do this depending. i only have Saturday and Sundays to work.

Busbey said:.................

if bare aluminum, use self etching primer lightly >

rustoleum aluminum primer 2 coats >

wetsand?

2 coats of preferred color rustoleum topside paint >

wetsand?

1 final coat of rustoleum topside paint>

clear-coat of sort?

for the bottom of the boat, should i use something else over the primer? what if i want to keep it the primer grey color? would that rustoleum aluminum primer be good for UV protection and not chip and flake off?

a serious THANK YOU for your help.

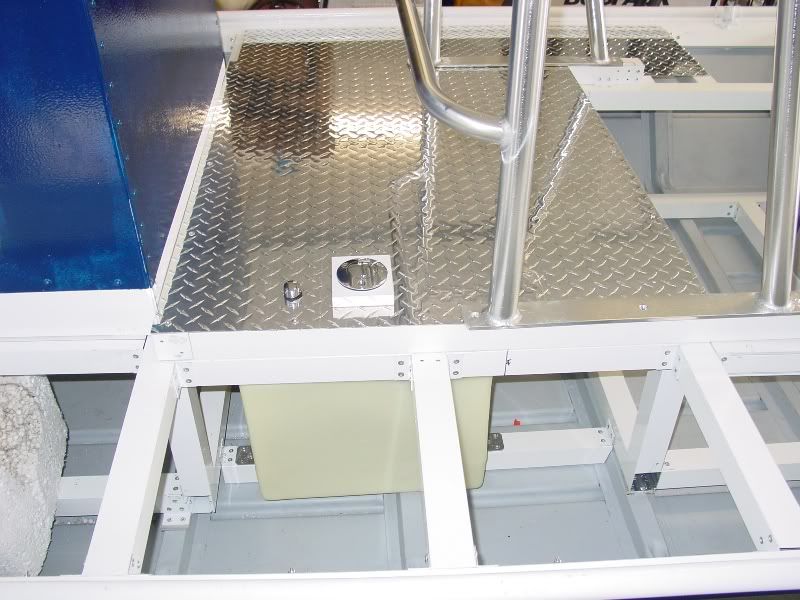

Hey Fever, The fuel tank fill and vent fittings are plumbed and the tank is decked over.JonBoatfever said:looks good, any updates?

I have a skill saw with a fine cabinet grade carbide blade that is the "go to" for cutting the larger sheets of DP (4 x 10)mmf said:Hey Jerry, I thought I used a lot of rivets on my diamondplate but I bet you have surpassed my number just on your framework! It's really looking good too! Are you going to cut the diamondplate with a handsaw? If so, thought I would give you my findings at least my experience doing it.....I tried using a carbide tipped blade at first but it gave me a very rough cut edge and it was hard to guide correctly for me, that's when I tried the fine tooth plywood blade which gave a much better cut and much more easy to guide, the only negative was having to pick the aluminum out between the teeth occasionally. I used a dental pick for this, and you must oil the blade alot. You can tell when it's time to pick the blade because it will stop cutting good and you will feel drag on the saw. It is very time comsuming cutting the aluminum too as you can't afford to make a mistake, as I measured and re-measured several times before I took the plunge! I hope this goes well for you! Keep up the great work ol-boy!