hockeyfish

New member

- Joined

- Jul 10, 2011

- Messages

- 2

- Reaction score

- 0

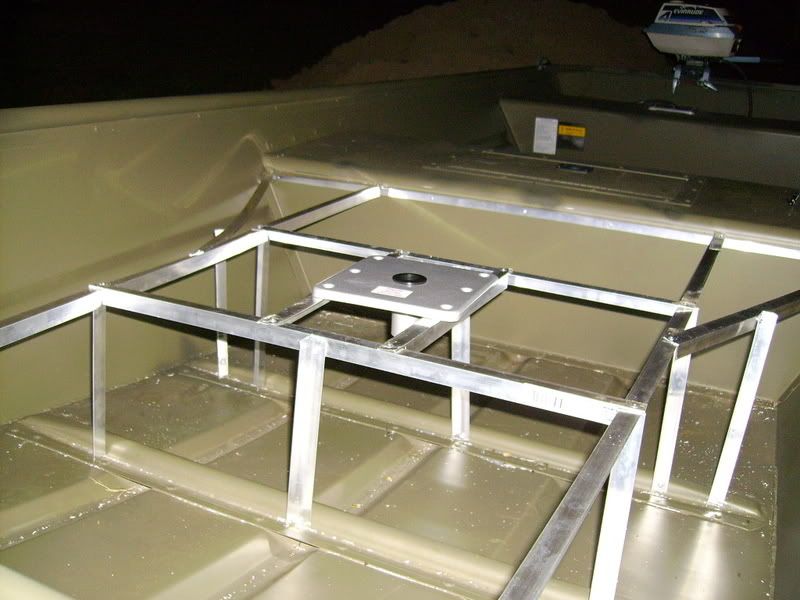

hey i'm thinking of starting to rebuild my 14' aluminum boat and i was just wondering what would be better to make all the flooring and what not, should i use aluminum angle for all the structure and bracings? ive read over many boat conversions and i see both used, is aluminum angle better because you dont have to worry about sealing it as you would need to for the wood?

any responses would be great,

thanks a bunch

any responses would be great,

thanks a bunch