onthewater102

Well-known member

Mudhole is running a great deal on a really outstanding line of graphite rod blanks at the moment, so I figured I'd put a thread out for anyone interested. These High Modulus blanks that are 35% off now are comparable to some of the very best blanks available on the market.

A custom rod isn't for everyone, but I've made a number for myself and learned they're an excellent way for me to cherry pick where I spend my money in the equipment I use - namely, the best blank I can reasonably afford and attaching to it durable lightweight guides that won't take away from its sensitivity by adding a lot of unnecessary weight, but I can build them to anyone's taste. On my setups I keep the reel seat and grips as lightweight and inexpensive as possible, using split grips with very little design embellishment (using bare winding checks as transitions from the blank to the grip, lightweight inexpensive components like EVA vs. cork, etc.) - but, again, I've built more ornate setups to the buyer's specification with a lot of cosmetic amenities - all a question of taste and cost.

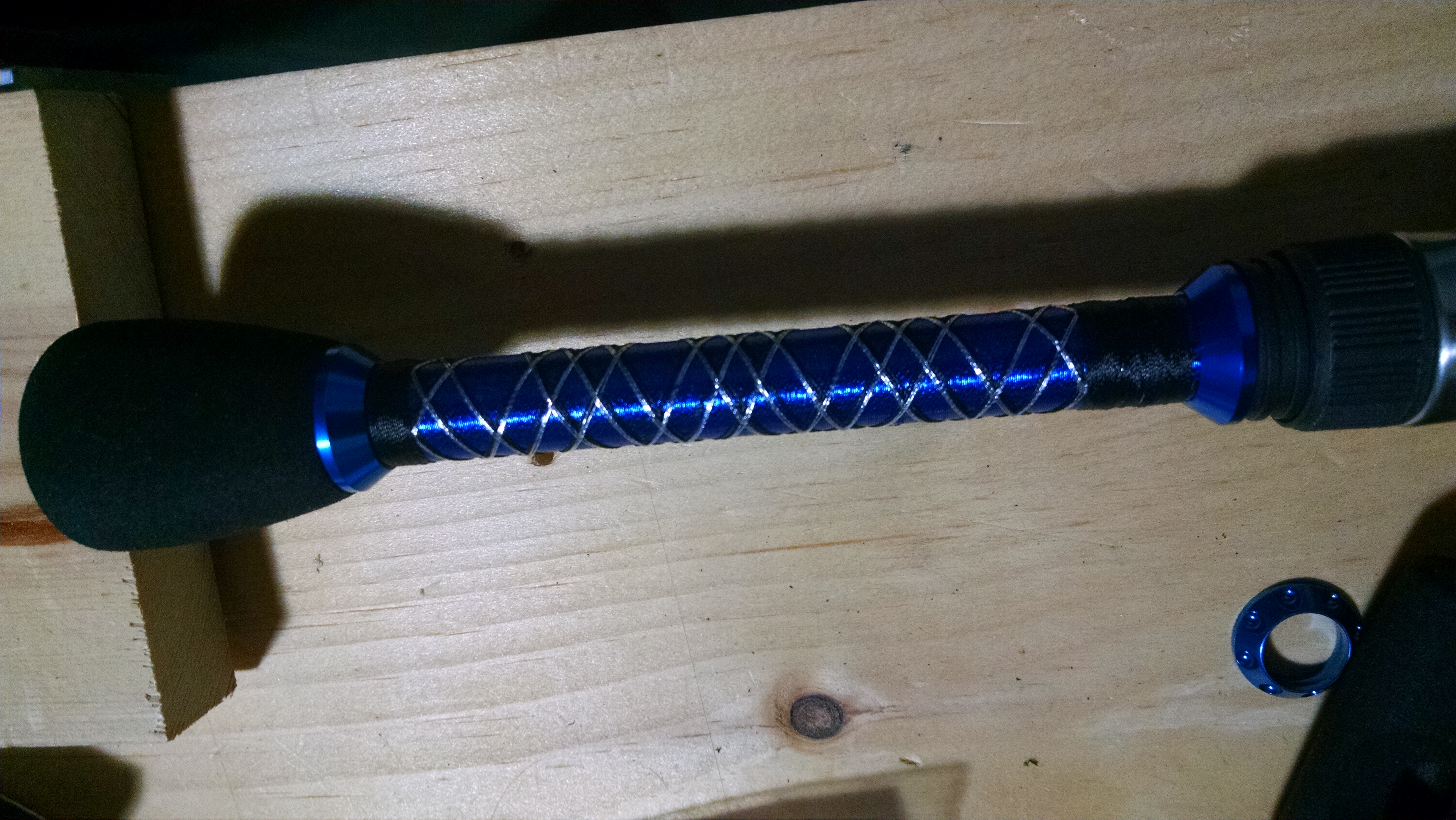

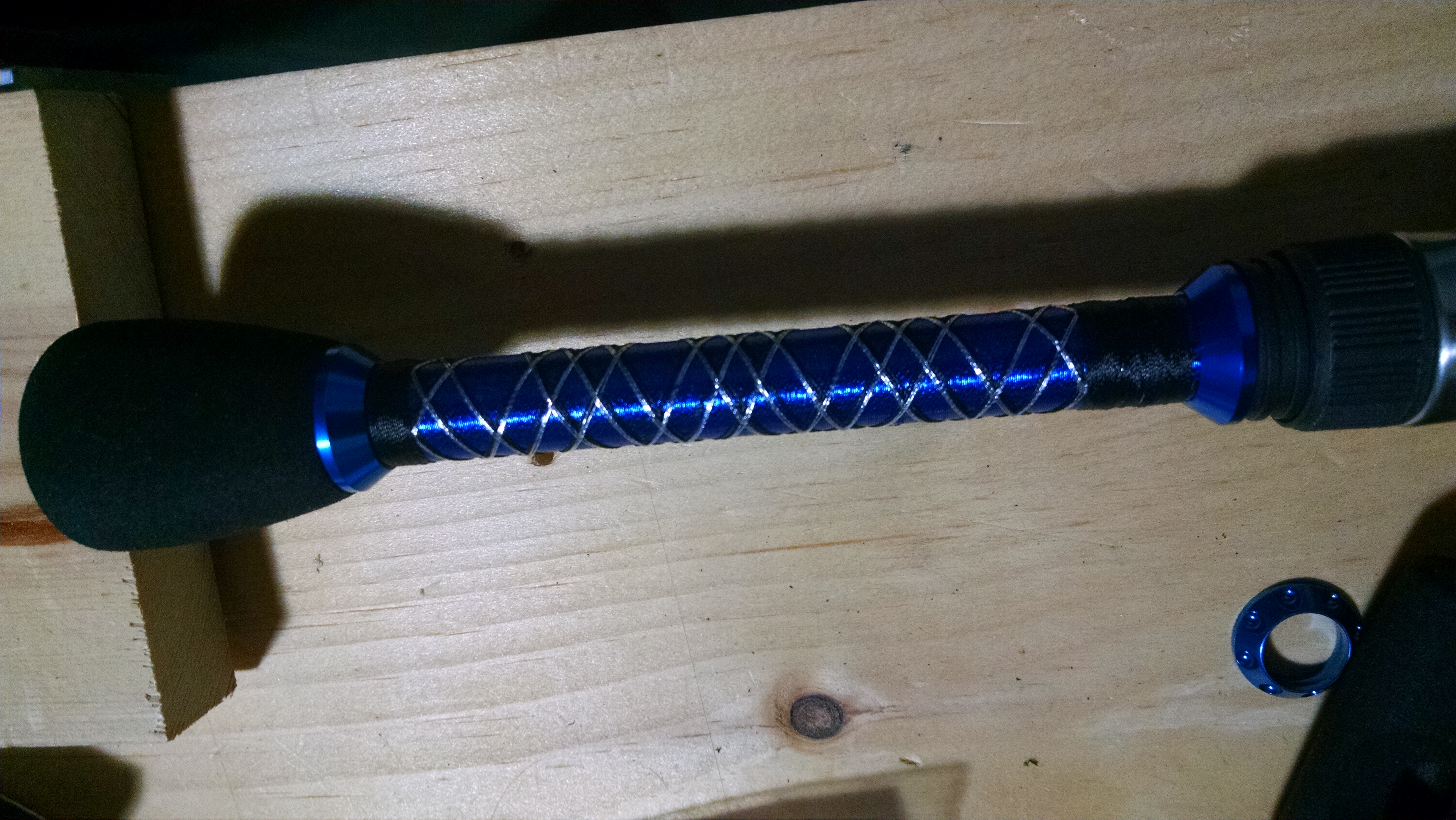

Some of the thread work I've done on rods for various people (all pictures taken before epoxy applied):

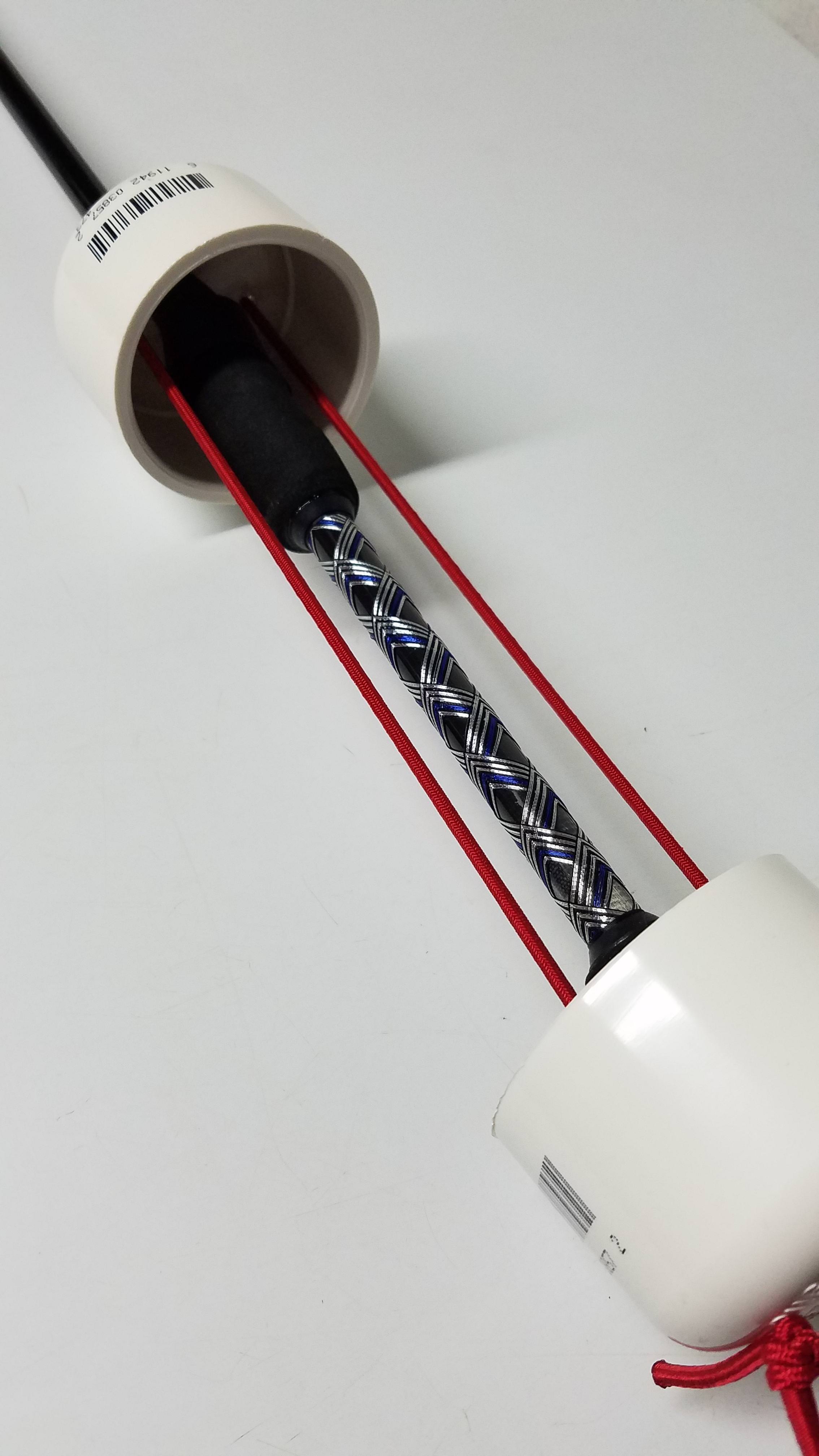

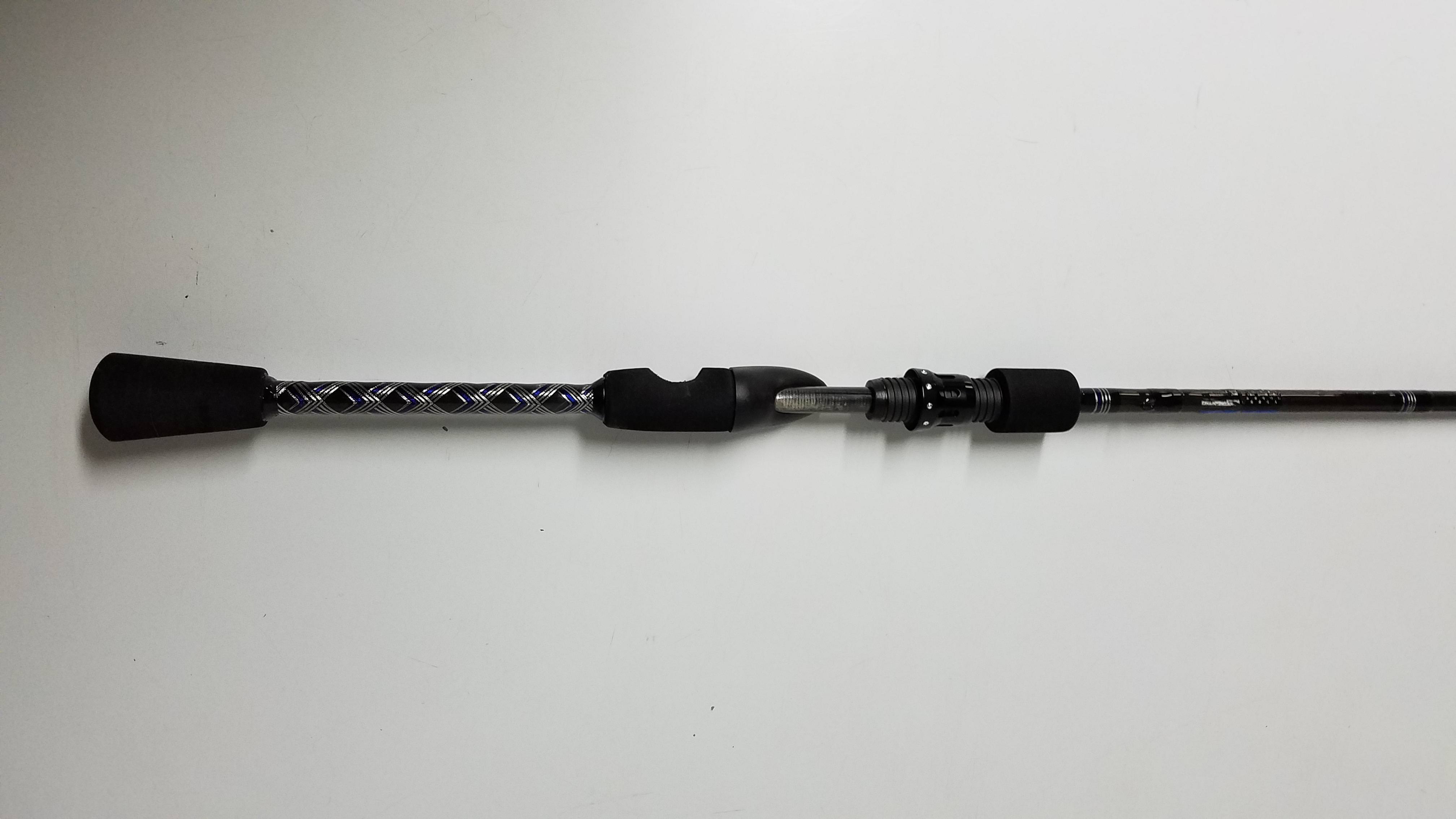

A few pictures of what I'm calling spartan split grips:

The blanks used in these rods weighed 2.7oz. The casting rods finished weighed 4.5oz - I didn't weigh the spinning setup in the mix.

It's a bit of an involved process, you'd be amazed at how many little component options are available for customization. If you're interested shoot me a PM to discuss what you're looking for and from there I can give you an estimate for what it will cost - but for a rod built on a $100 blank, a minimalist grip and zirconia ceramic guides (an intermediate in quality between Fuji Alconite guides and their high end SiC guides) the complete setup would be approximately $250. The same setup with Fuji Torzite guides (best available on the market) would be approximately $350. These MHX blanks are lighter than St. Croix SCV series, so the final product could potentially be comparable performance-wise to commercial rods in the $450+ range.

A custom rod isn't for everyone, but I've made a number for myself and learned they're an excellent way for me to cherry pick where I spend my money in the equipment I use - namely, the best blank I can reasonably afford and attaching to it durable lightweight guides that won't take away from its sensitivity by adding a lot of unnecessary weight, but I can build them to anyone's taste. On my setups I keep the reel seat and grips as lightweight and inexpensive as possible, using split grips with very little design embellishment (using bare winding checks as transitions from the blank to the grip, lightweight inexpensive components like EVA vs. cork, etc.) - but, again, I've built more ornate setups to the buyer's specification with a lot of cosmetic amenities - all a question of taste and cost.

Some of the thread work I've done on rods for various people (all pictures taken before epoxy applied):

A few pictures of what I'm calling spartan split grips:

The blanks used in these rods weighed 2.7oz. The casting rods finished weighed 4.5oz - I didn't weigh the spinning setup in the mix.

It's a bit of an involved process, you'd be amazed at how many little component options are available for customization. If you're interested shoot me a PM to discuss what you're looking for and from there I can give you an estimate for what it will cost - but for a rod built on a $100 blank, a minimalist grip and zirconia ceramic guides (an intermediate in quality between Fuji Alconite guides and their high end SiC guides) the complete setup would be approximately $250. The same setup with Fuji Torzite guides (best available on the market) would be approximately $350. These MHX blanks are lighter than St. Croix SCV series, so the final product could potentially be comparable performance-wise to commercial rods in the $450+ range.