It has taken me over 50 years to learn all these tips and tricks

through my own trial and error or watching other tradesmen

work their magic..... shortcuts can come back to bite you later.

yes, bare plywood or one coat of primed plywood will last a very long time

IF kept in a garage all its life . . . outside covered traps moisture and will

slowly degrade any wood you may have. (over time).

I use quite a bit of Kilz for different projects so I have become very familiar

with the product...... it dries fast and does not really seep into the wood fibers

on plywood. On tight grained lumber, such as pine, spruce or douglas fir,

the surface primer is all that is needed for a good weather-proof finish.

woodworking is my forte' - preservation and finishing is my passion.

all I can do is share the information with you. It is totally

up to you as how to proceed in your project.

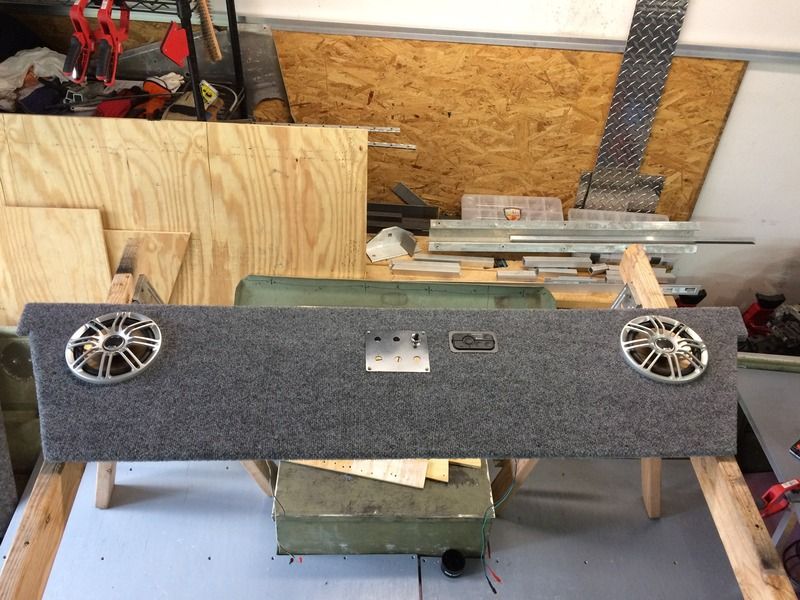

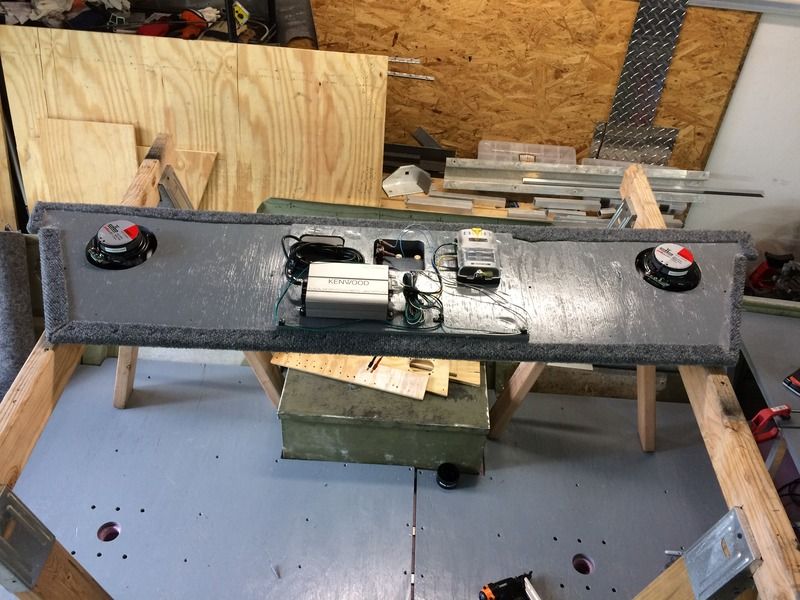

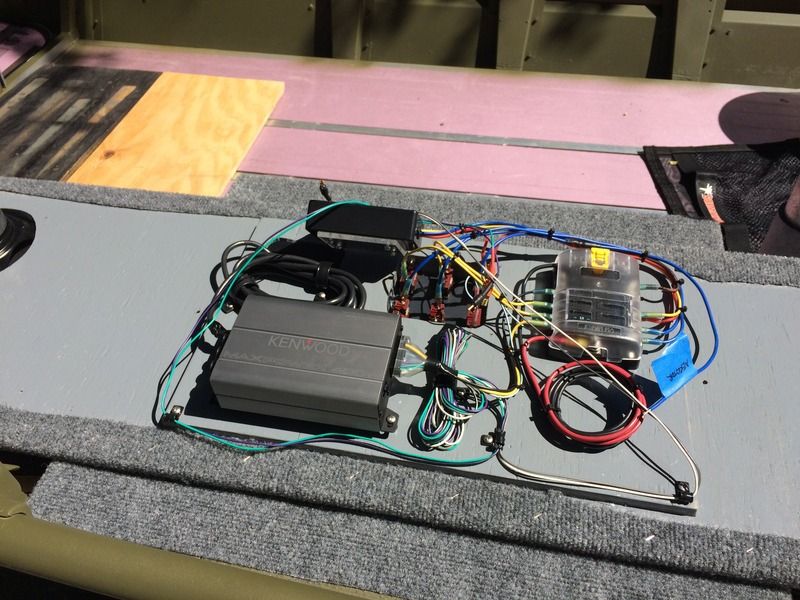

again - awesome craftsmanship !!! job well done.

This is a 4'x6' sandblasted wood sign made of Florida Cypress I made 20 years ago.

it was properly primed with oil base primer with the 50%, 25% and 10% formula.

It has been cleaned and repainted a few times over the years but it is still sound

with no rot. The secret to a successful exterior project is equal coats of coatings

on all edges, front

and back.

.