SkagBass

Well-known member

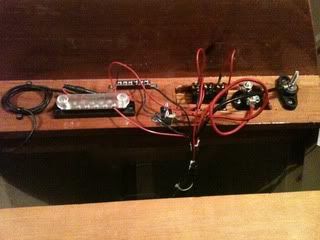

The project is coming along. I am still waiting for some electrical supplies to show up - come on Fed-Ex , just leave it at the door!

I got the flooring cut and fitted. The pedestal seat bracket is installed. I did some rattle can paint (for now) to make the boat picture pretty and I will be installing all of the wood parts this weekend. I should have a new set of pics on Monday =D>

One more paycheck and one more weekend and it will be time to go fish. That was the whole point in doing this, I think. #-o

I got the flooring cut and fitted. The pedestal seat bracket is installed. I did some rattle can paint (for now) to make the boat picture pretty and I will be installing all of the wood parts this weekend. I should have a new set of pics on Monday =D>

One more paycheck and one more weekend and it will be time to go fish. That was the whole point in doing this, I think. #-o