Last summer I purchased a 14' Cadillac boat, which included a trailer and Evinrude 15hp outboard. It was a slow drive home to keep the wheel bearings cool but got it home. Immediately installed new wheel bearings and seals. Fast forward to fall, the engine would not run so ultrasonic carb cleaning & carb kit, new fuel lines & pump. I made it out to the lake for the maiden voyage/test run and deemed the boat a keeper.

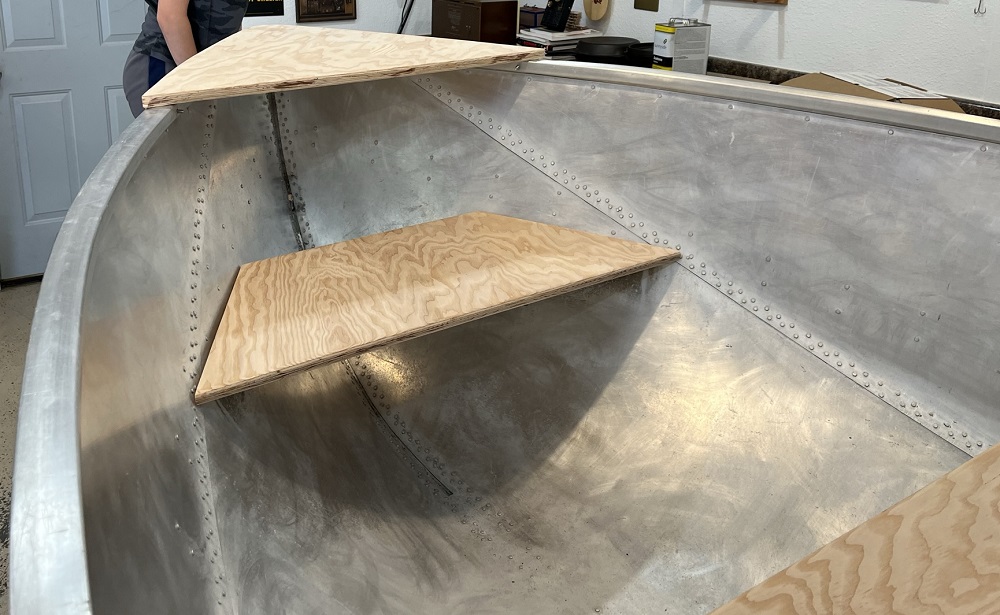

After a long pause and now with summer here I began working on the boat. In looking for ideas and advice I quickly found this great forum, thank you everyone. First job was to remove all of the hardware to include the seat tops as I really wanted to see the condition of the floatation foam. The floor looks to have originally been painted with a textured gray paint but luckily 90% was worn off, Jasco premium paint remover took care of the rest. Finally removed lots and lots of stickers; DNR rules, fish rulers, fish id charts, registration stickers over old registration stickers. With a bare boat I cleaned the entire boat with aluminum brighter from NAPA, wow this stuff is amazing. Lots more work to come, no questions yet but I am sure there will be some.

After a long pause and now with summer here I began working on the boat. In looking for ideas and advice I quickly found this great forum, thank you everyone. First job was to remove all of the hardware to include the seat tops as I really wanted to see the condition of the floatation foam. The floor looks to have originally been painted with a textured gray paint but luckily 90% was worn off, Jasco premium paint remover took care of the rest. Finally removed lots and lots of stickers; DNR rules, fish rulers, fish id charts, registration stickers over old registration stickers. With a bare boat I cleaned the entire boat with aluminum brighter from NAPA, wow this stuff is amazing. Lots more work to come, no questions yet but I am sure there will be some.