I got my Dr. Frankenmotor on, restored this old 88 Merc 60hp using the cowling and starter from an older setup and a full rebuild of the carbs, fuel pump, impeller, pivot, steering tube and who knows what else. Adjusted the timing and idle settings in the backyard and set the max spark advance per the FSM & have the thing purring like a kitten on the muffs.

Finished the reinstallation of the shifter controls and helm, cracked as it is, to be used as a form and coated over in fiberglass at a later date.The original helm is some sort of plastic (poly by the way it seemed to melt and refuse as I cut it with the reciprocating saw in places) and doesn't seem to be responding well to my plastic welder.

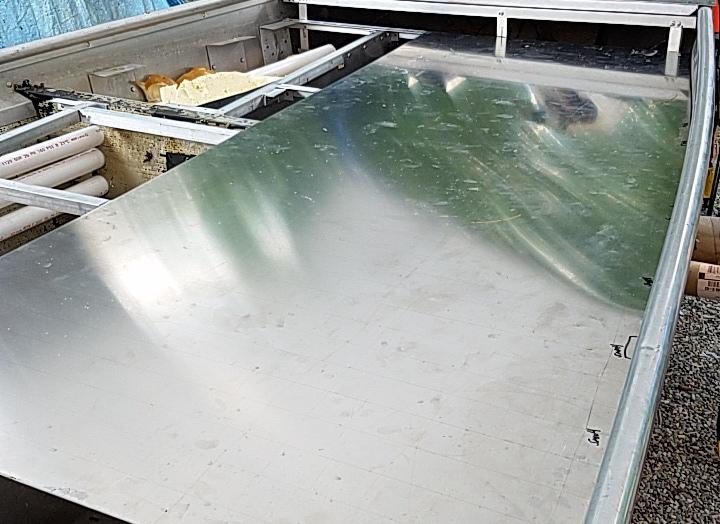

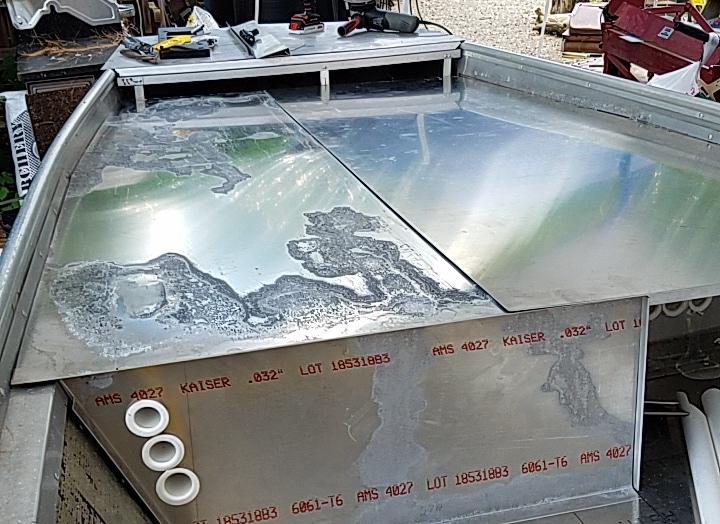

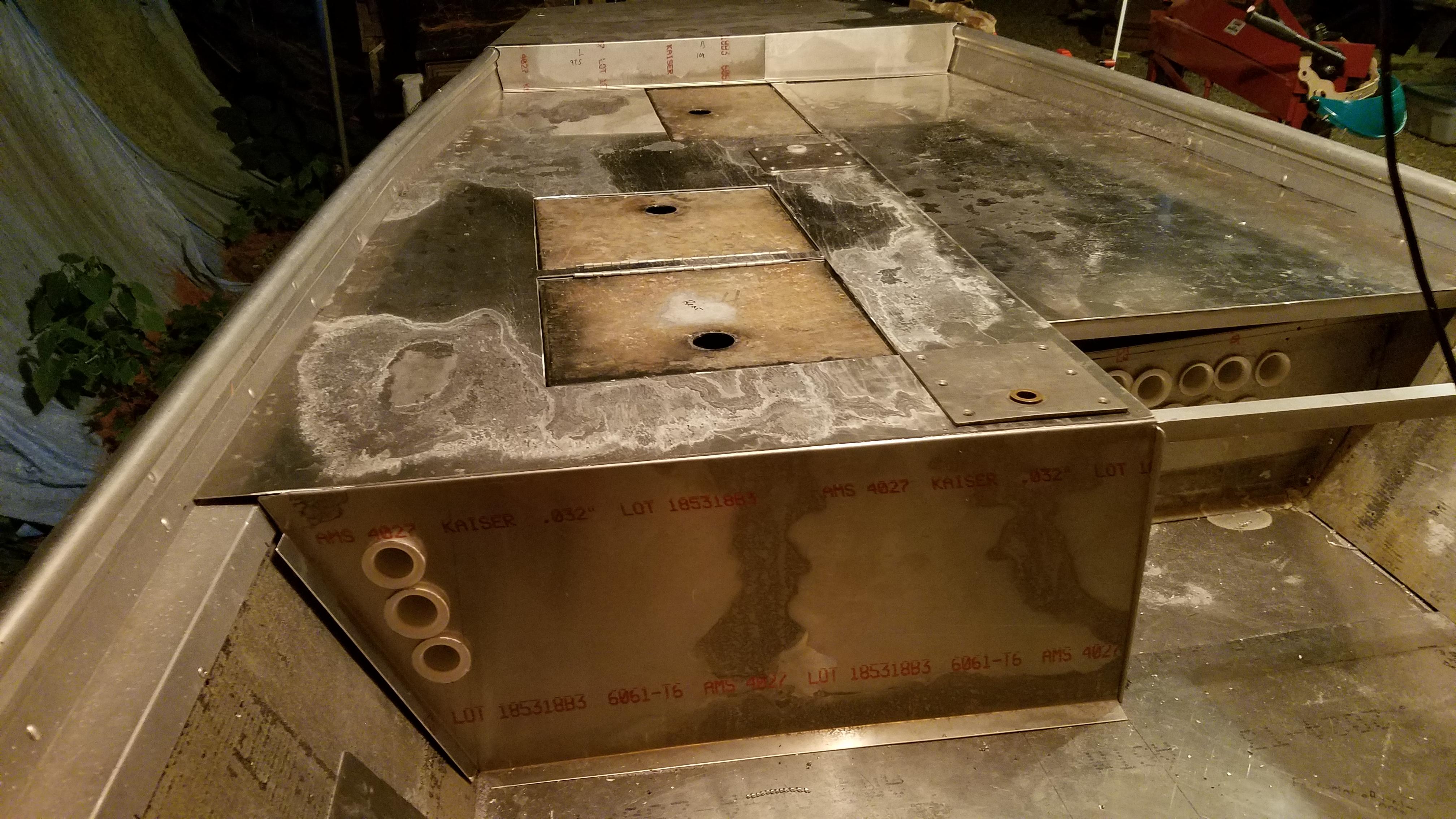

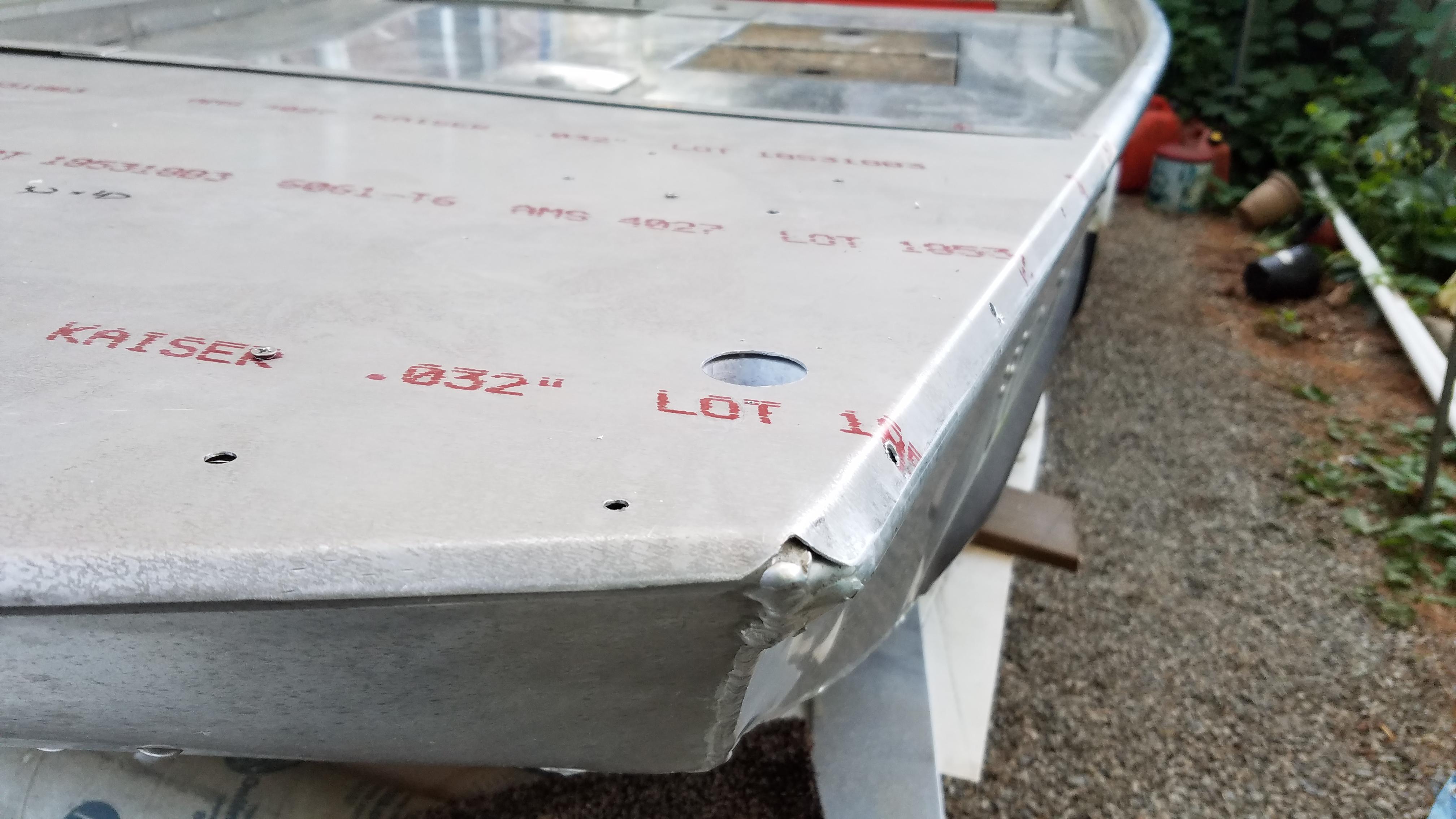

Plenty of odds and ends were done on the front deck that didn't get pictures including building the door for the rod locker, installing the new fuse box and rewiring everything, adding provisions for a pair of fish finders, replacing the livewell pump motor, bilge pump, circuit panel in the bow with the USB charger & 12v socket, separate red & green nav lights, trolling motor outlet, installing hatches & trim around the hatch openings, fabbing up a lure rack for along the gunwale in the front and probably a few dozen other little items. Also stripped any old carpet backing still glued to the rear deck and removed all but the most stubborn of the old carpet glue. Tracker did such a piss poor job laying out the rear deck it's just an overlapping collage of sheet metal and rivets I'd never be able to paint over it and have it come out clean so I ordered carpet for just the rear deck and Tuff Coat for the front 2/3 of the boat. Prior to prepping it all for paint it looked like this:

Spent a considerable amount of time taping around the edges and even more time cleaning, sanding, and cleaning all the surfaces to be painted before applying primer. All in the prep work was a full day's worth of time.

Finally got to painting from the middle bench forward over the Memorial Day weekend, so the front 2/3 of the boat are close to done, just a few bleed-throughs to be cleaned up where either the paint or primer made their way through the taped off areas to the surfaces below, mainly on the electrical sockets up front.

Bench cushion rivets to be installed now that the bench is painted, and the bench cushion shortly thereafter. Only things remaining now are the rear carpet, livewell remote controls and pull cord modification to the Terrova that I think I'll make a separate thread for.