88basstrack

Member

So this is my first time posting on this forum, I've been lurking since starting this project about 10 months or so ago. Let me start out by saying a couple things about myself and my old man, who helped a ton. I am 22 years old and I am working on a computer science bachelors degree at FAU part time while working with my dad on marine air conditioning (odd i know,computer science and an extremely labor intensive job, but I love working with my hands and working on computers). My old man is super cool and has some really awesome stories about life. He has his own marine air conditioning business that he started in 2001, he's a one man butt kicker if you will, especially doing this stuff for 30+ years lol. The overall goal of this project was to scarp out ALL of the broken Air conditioning equipment that we've accumulated on the side of the house over the years to pay for the restoration of the boat. As you can tell we barely even dented it hahaha. Back to the marine air conditioning because thats the key to this, we have a few perks in the marine industry, such as cheaper parts and some really nice friends with connections :lol: .

This is where I started at

I have already finished the boat as of 5/10/16 and ill throw a picture of it up as it sits now in a couple days, but ill update this thread day to day because i honestly don't have enough time on my hands to type up everything and put all the pictures in (i have 3 classes for the summer and still working with the old man) lol. The best part about this whole project was probably working with my dad on it and hearing how he used to fish with it and what he wanted to change about it.

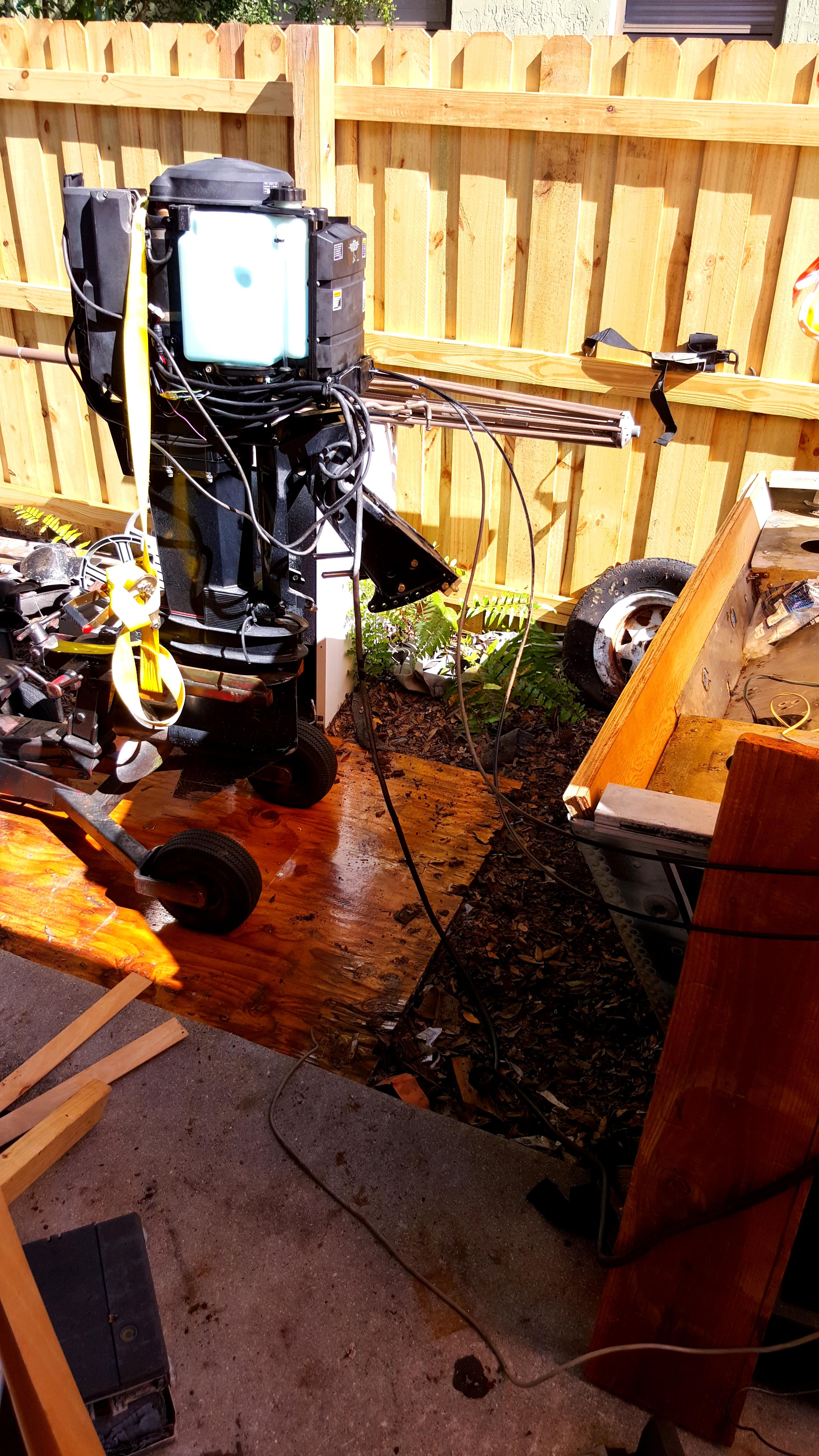

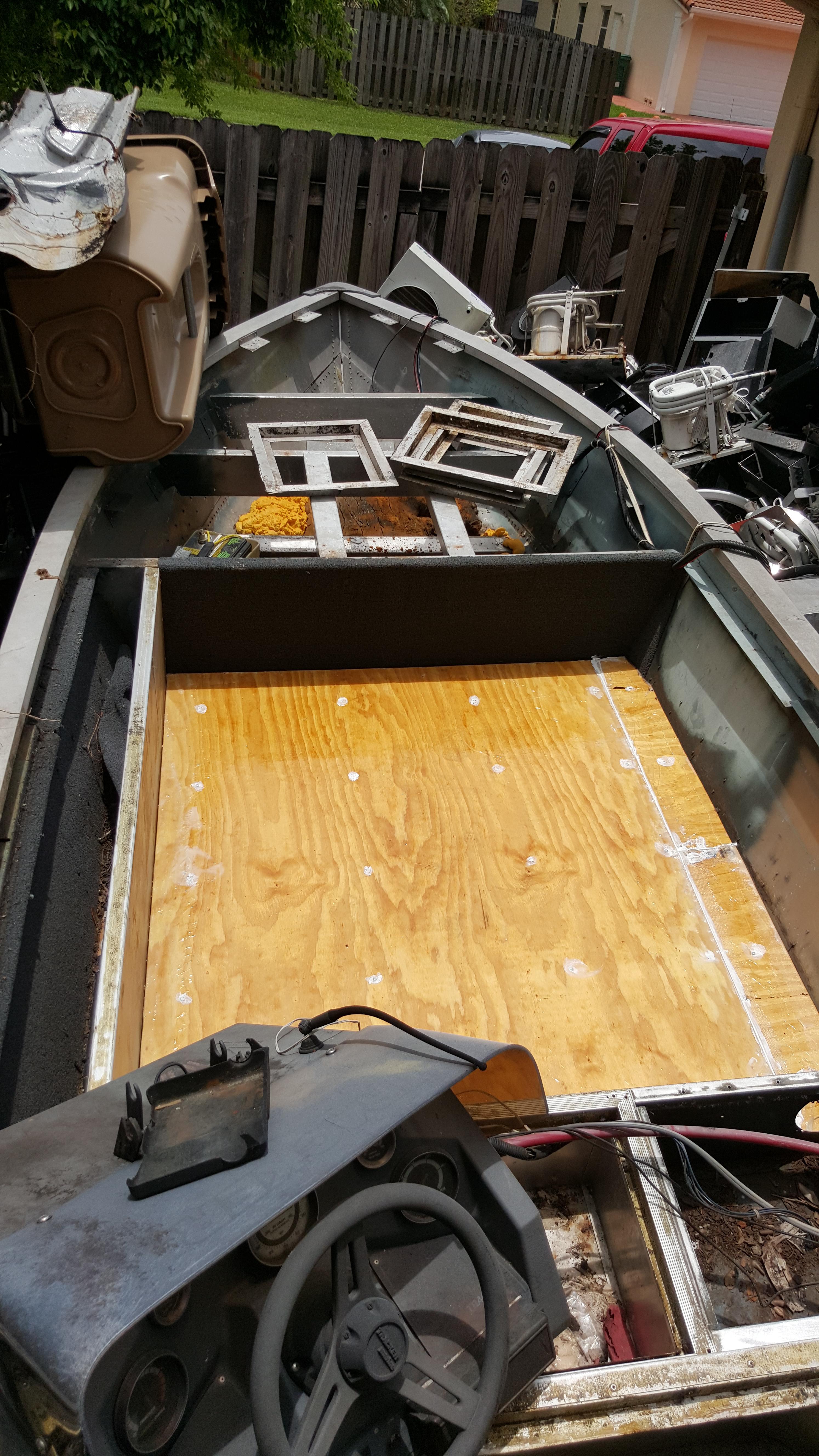

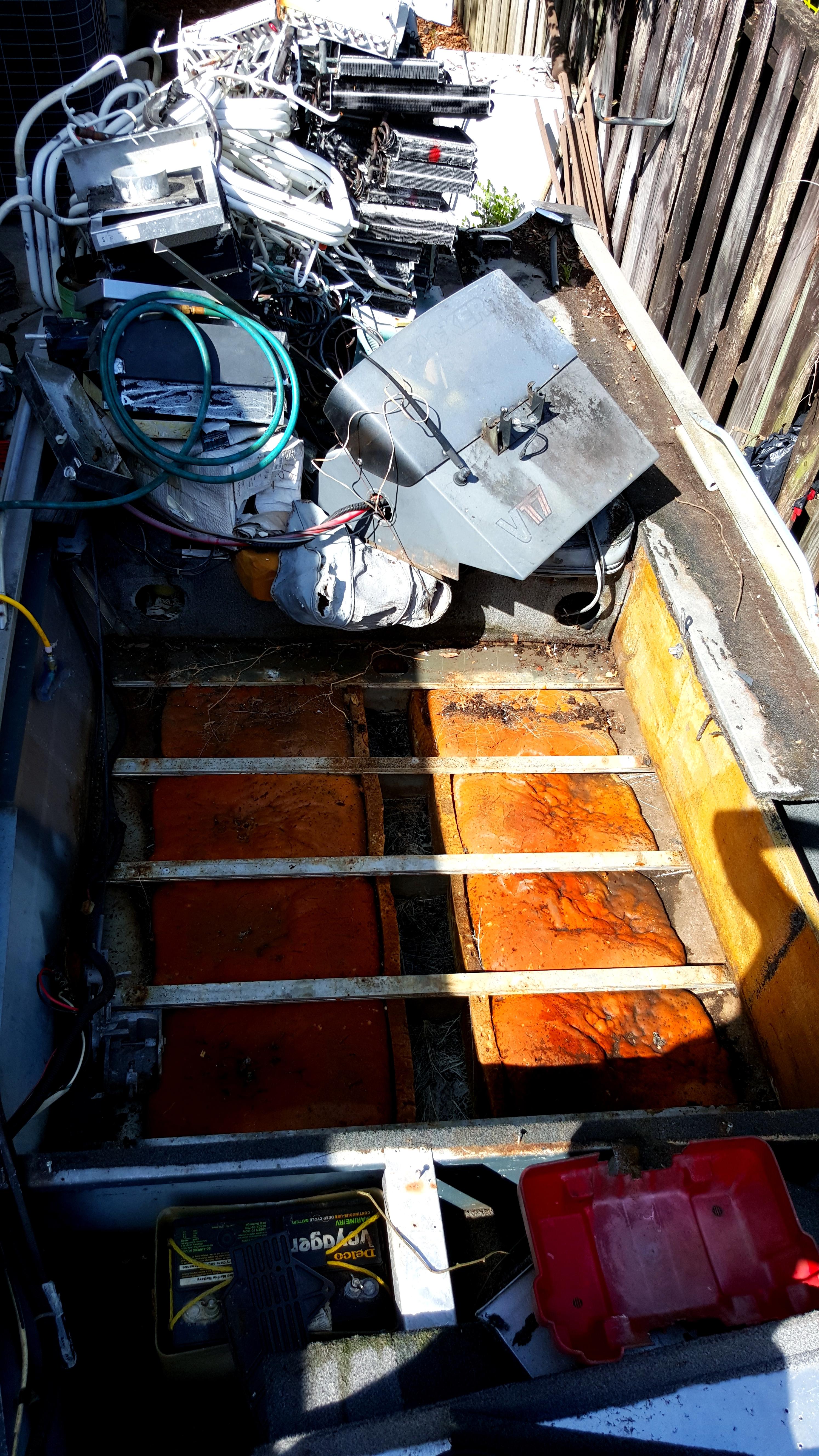

Sooooo onto the boat, its a 1988 Bass Tracker V17 with a Mercury 70 hp 2-stroke, back in 1988 my dad couldn't afford any "sparkly" bass boats out at the time, so he bought this Tracker to fish with instead lol. Although, he used to fish tournaments with his buddy who had a badass kevlar hull Storm back in the day :shock: so this motor had about MAYBE 100 hours on it so we knew that was at least salvageable. It sat from 1995 till 2015, untouched and out in the brutal Florida weather. The first step was to get all the vines, leaves and of course the 1988 rotten wood out of the boat and start from a clean slate.

7/11/15

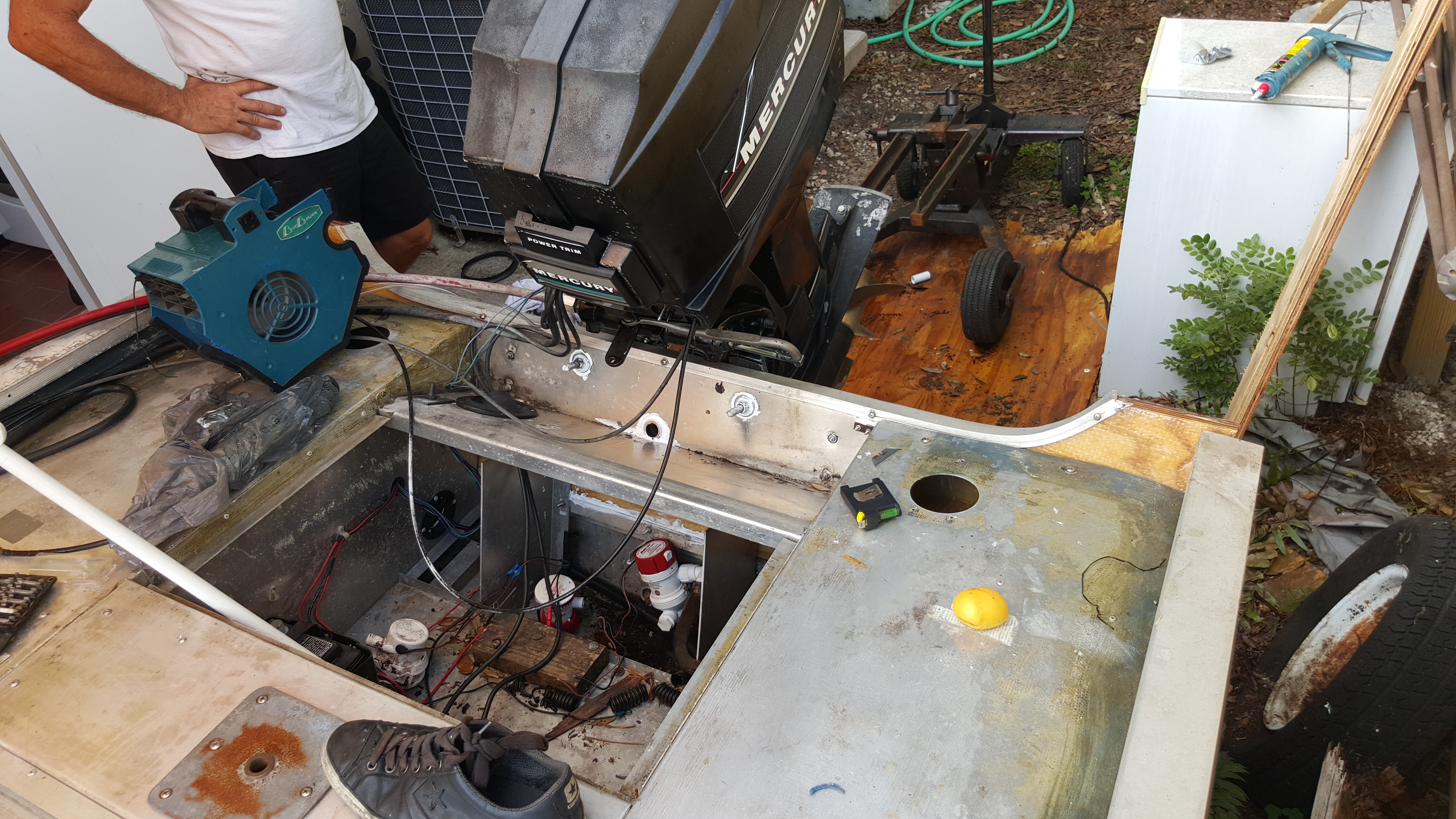

I mean this was intimidating to say the least!!

This was all the evaporators and condenser tubes we pulled out of boats throughout the years stacked on the bass boat, i think with that load we had about 400 lbs of them going to the scrap yard.

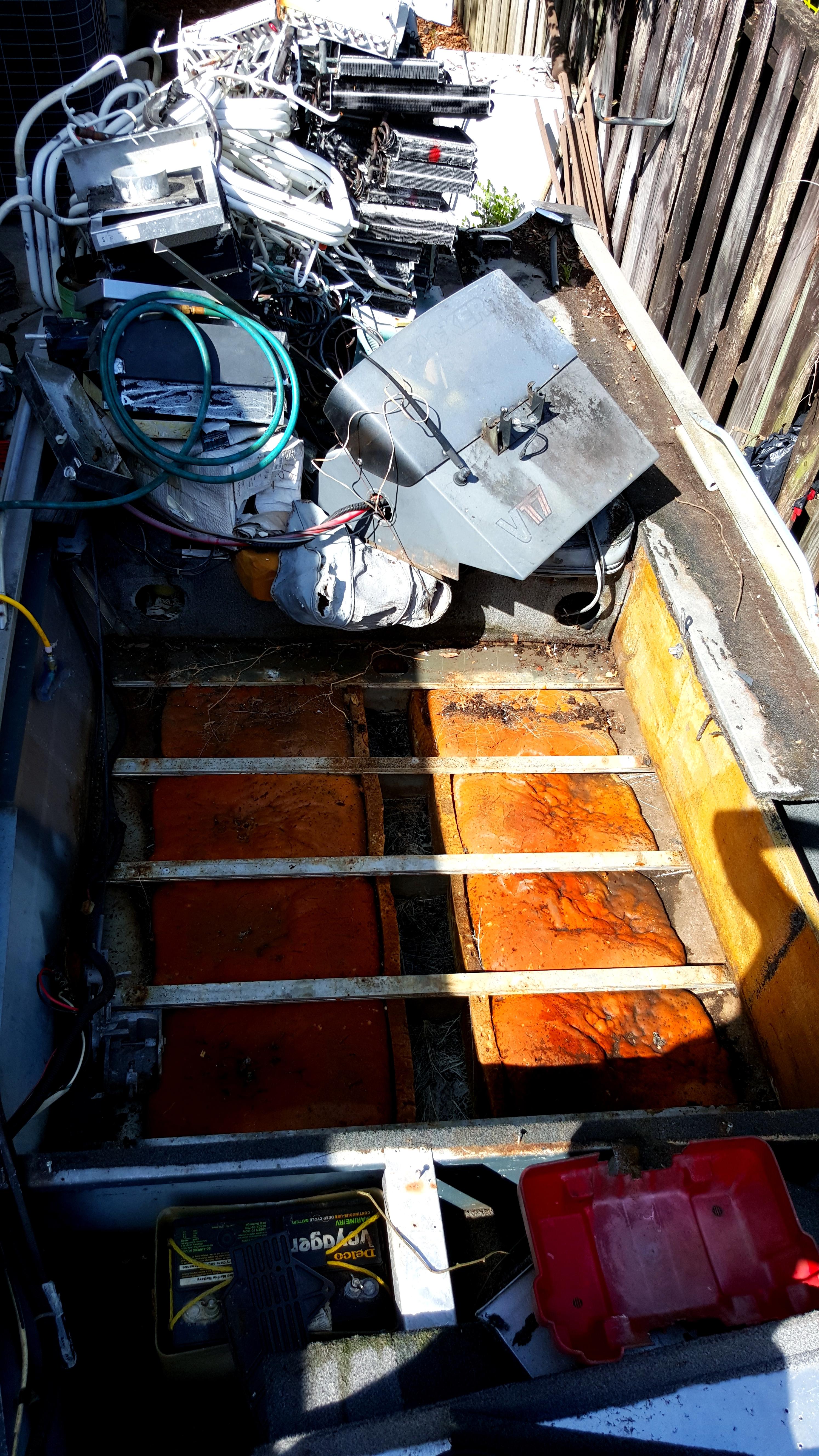

The foam was the number one thing i was worried about in this project, thankfully the drain plug has always been out through the years and all the core samples i drew were dry as a bone!!

7/18/2015

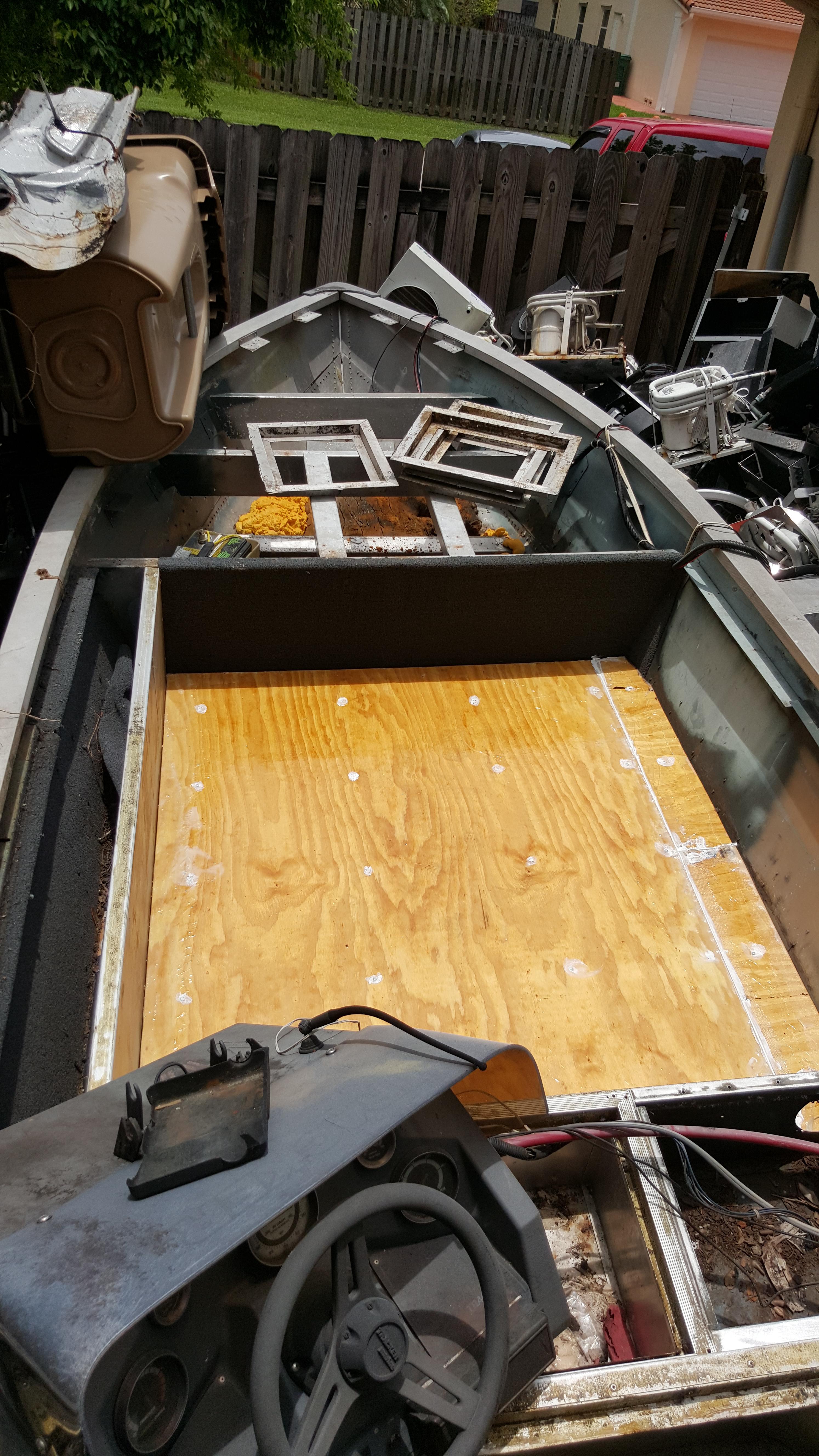

This picture was the plywood coated vs uncoated. We used West Systems epoxy resin 105 and fiberglassed matted one side (i can't seem to remember the weight of the glass though, but if anyone wants to know ill figure it out). The was probably the most hated part of the whole thing lol you just can't seem to get the resin off of you :x .

we first applied a liberal coat of resin and hardener to the wood, let it cure until a bit tacky and then laid the mat on and poured more resin on top, next we had to get all the air pockets out with a spiky roller type deal. And no this was not marine grade but it sure is now lol.

Test fitting the lower deck, the way this particular tracker was made, you had to use one entire width of 1/2 inch plywood plus a sliver cut from some of the transom wood. I believe they were able to put together the entire boat with 2 sheets of 1/2 inch plywood and go boat to boat with 3/4 inch plywood just for the transom that was sandwiched together with the 1/2 inch to create a 1.25 inch transom piece.

7/25/15

Progress was good to see at this point

7/26/15

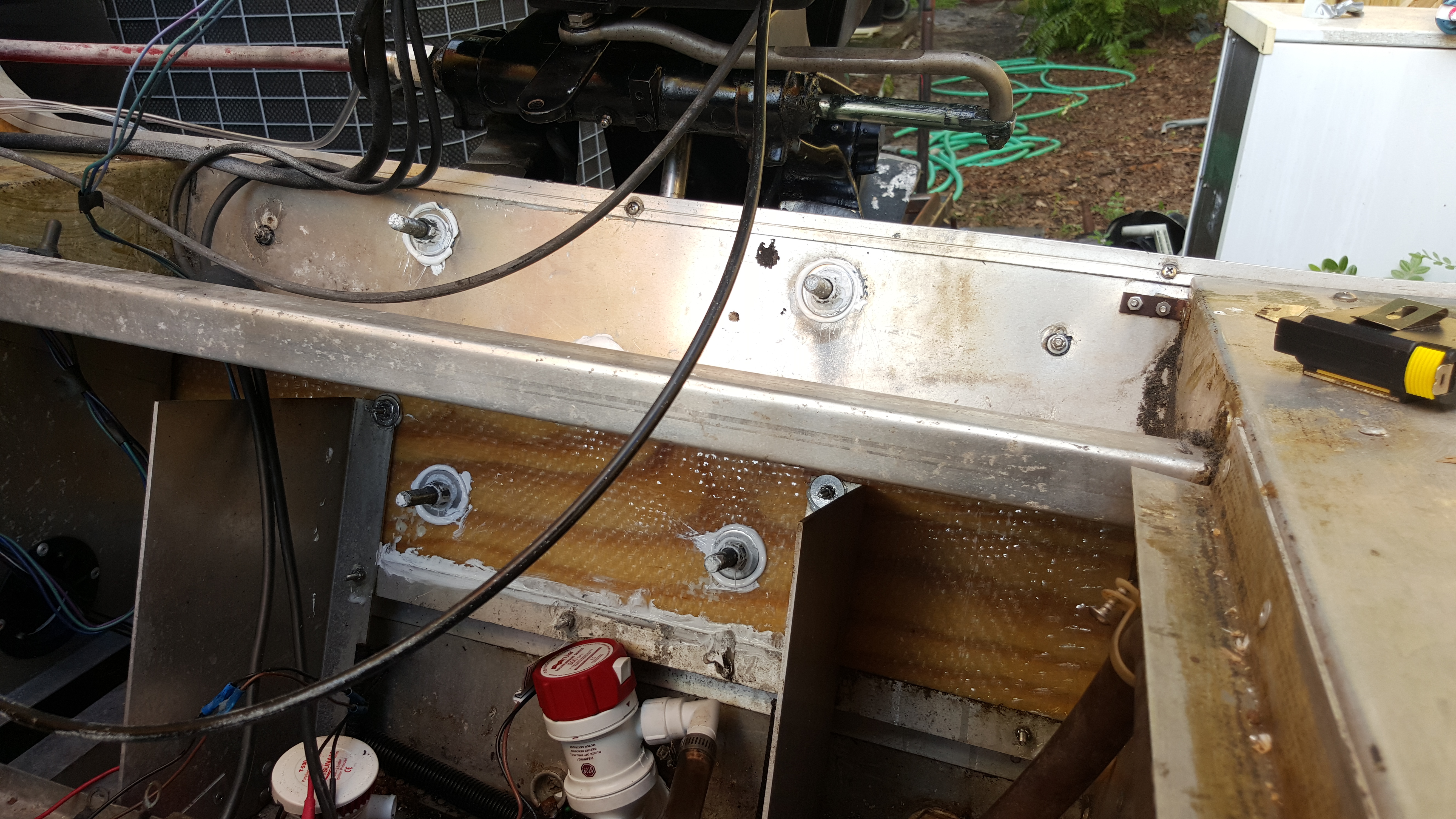

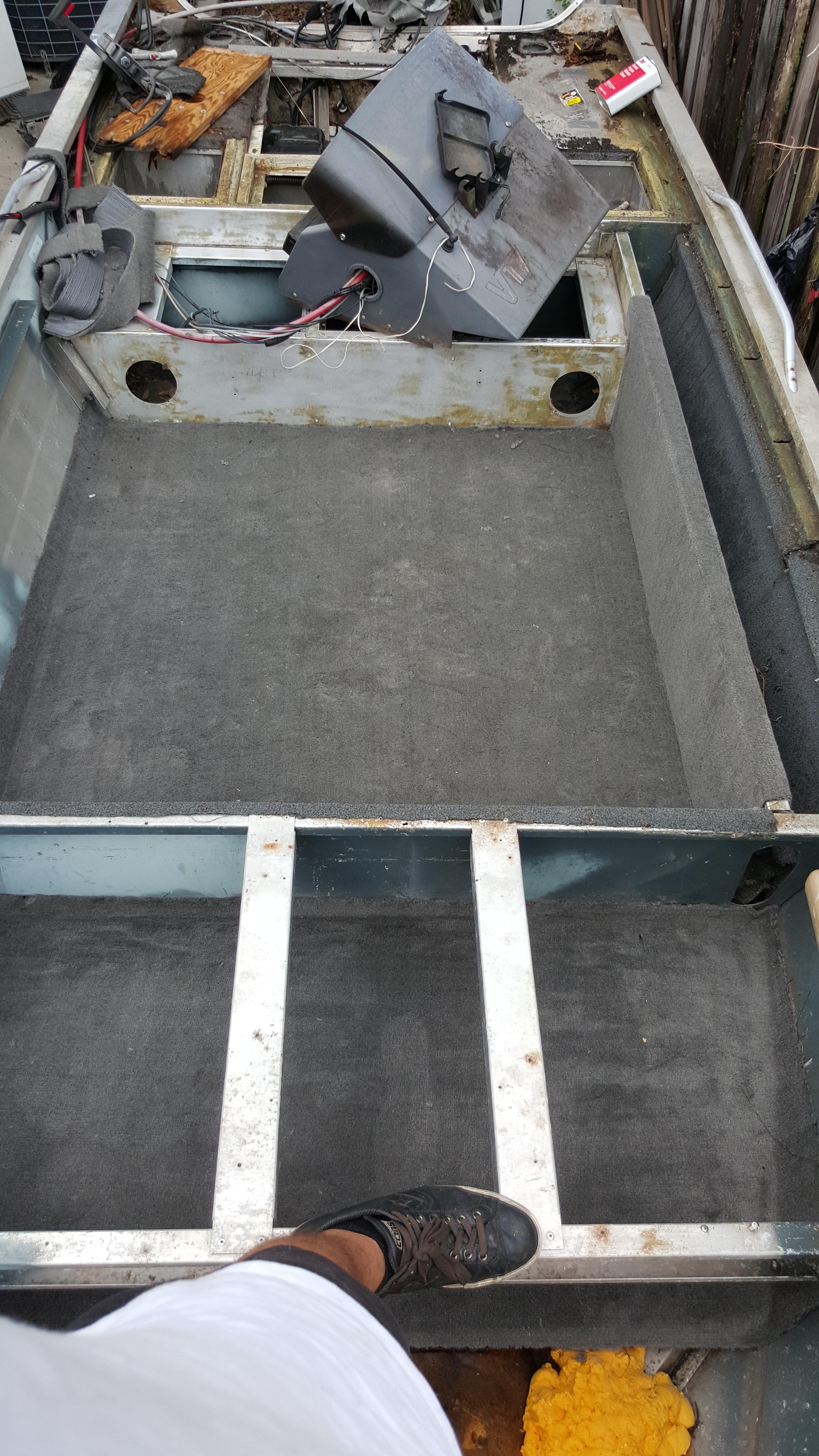

All screws were stainless and bedded down with boat life.

Console isn't in the greatest condition, but the gauges work and we are not even close to being that good at fiberglassing, to make a new one!

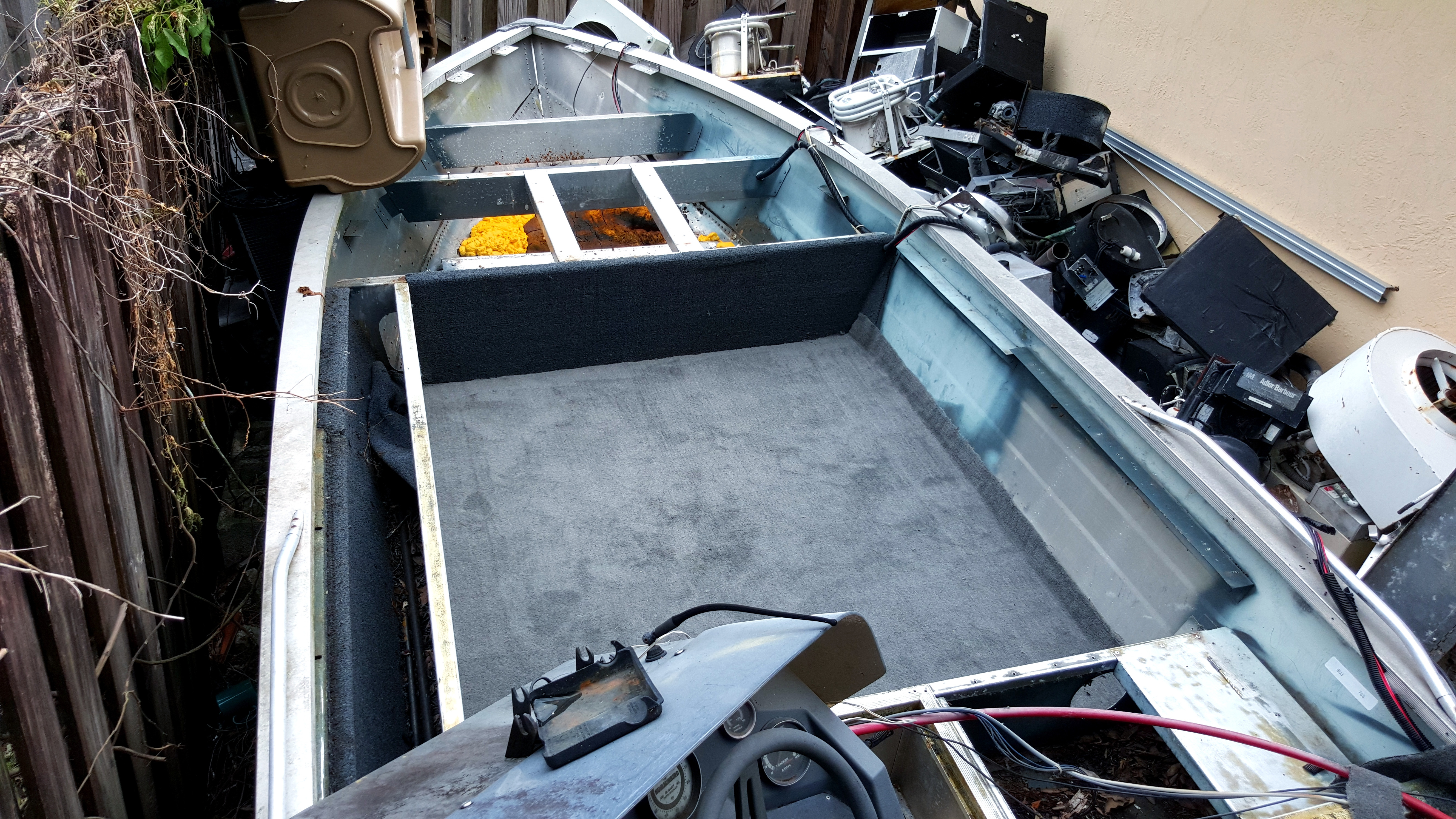

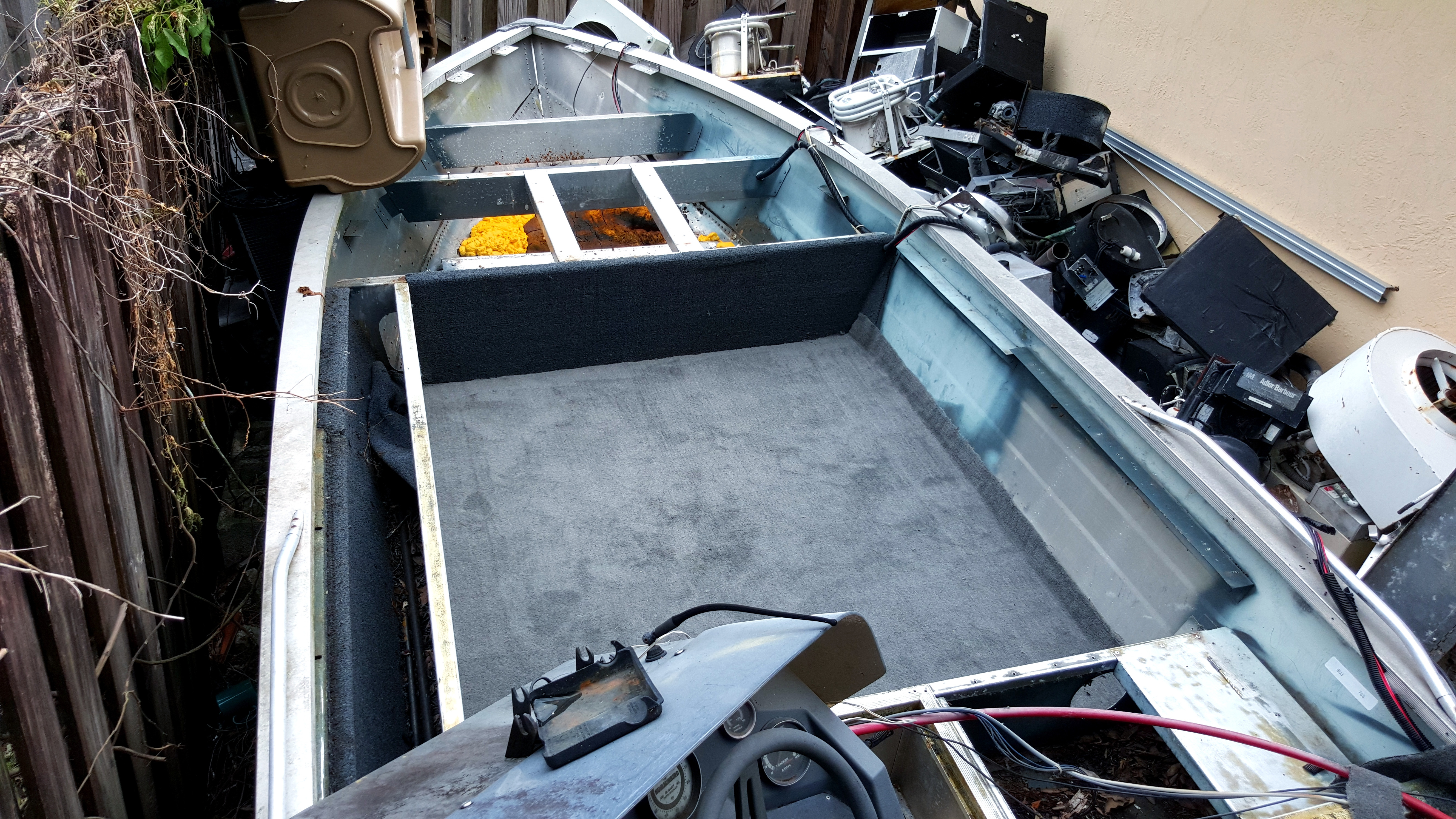

got the carpet glued down for the main decks the same day we mounted them down.

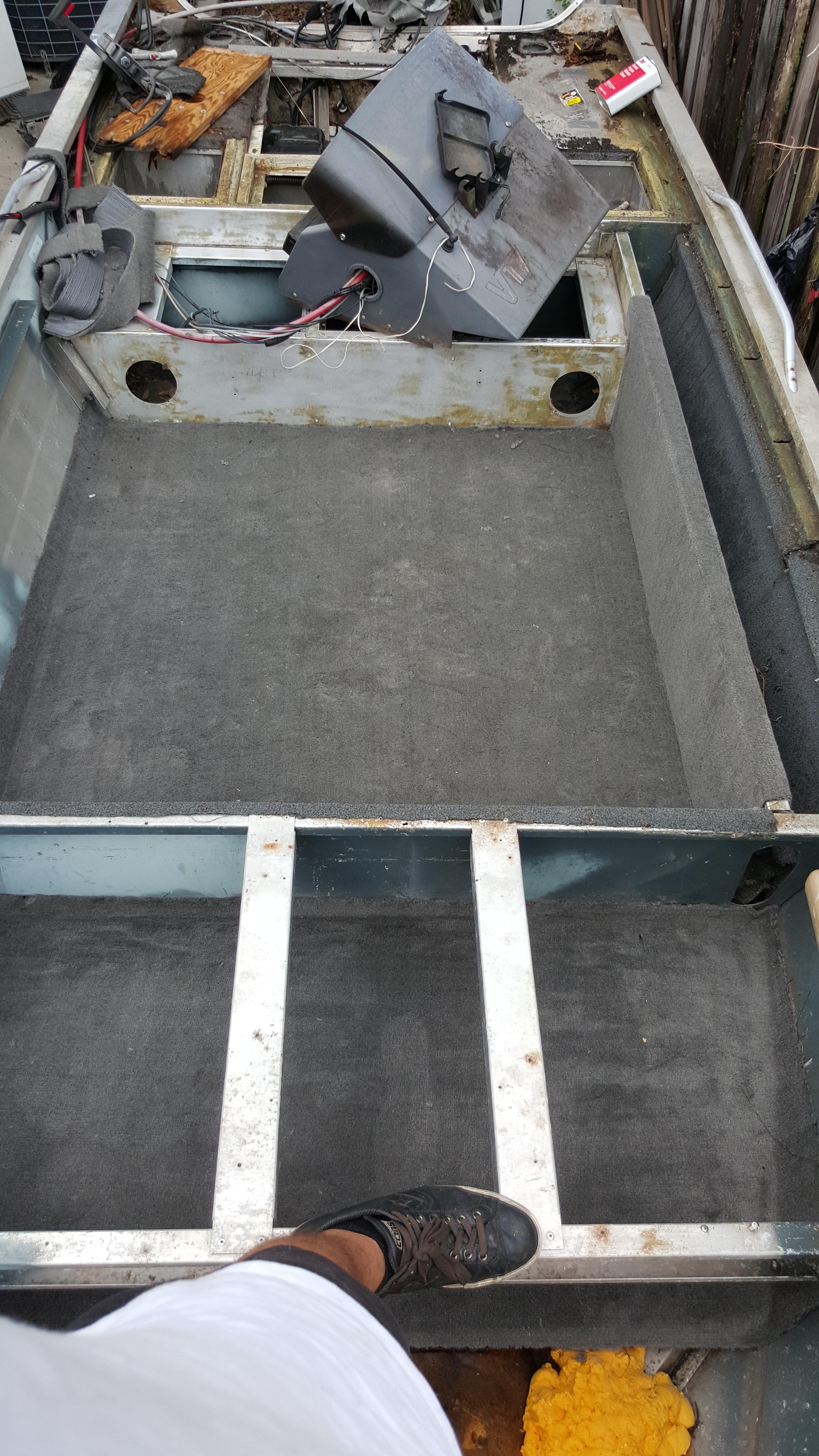

In this picture i finally took apart the back casting deck where the seat post goes into, my dad and i were under the impression that it was just aluminum framing under it. lo and behold, its a plank of 3/4 inch wood. We replaced that with whats called Starboard. its like a plastic composite material, super strong and super heavy duty. We actually tossed up that option to replace the transom with starboard because it'll never rot out, but 6 ft by 2ft by 1.25 inch would be extremely heavy and costly.

This is where I started at

I have already finished the boat as of 5/10/16 and ill throw a picture of it up as it sits now in a couple days, but ill update this thread day to day because i honestly don't have enough time on my hands to type up everything and put all the pictures in (i have 3 classes for the summer and still working with the old man) lol. The best part about this whole project was probably working with my dad on it and hearing how he used to fish with it and what he wanted to change about it.

Sooooo onto the boat, its a 1988 Bass Tracker V17 with a Mercury 70 hp 2-stroke, back in 1988 my dad couldn't afford any "sparkly" bass boats out at the time, so he bought this Tracker to fish with instead lol. Although, he used to fish tournaments with his buddy who had a badass kevlar hull Storm back in the day :shock: so this motor had about MAYBE 100 hours on it so we knew that was at least salvageable. It sat from 1995 till 2015, untouched and out in the brutal Florida weather. The first step was to get all the vines, leaves and of course the 1988 rotten wood out of the boat and start from a clean slate.

7/11/15

I mean this was intimidating to say the least!!

This was all the evaporators and condenser tubes we pulled out of boats throughout the years stacked on the bass boat, i think with that load we had about 400 lbs of them going to the scrap yard.

The foam was the number one thing i was worried about in this project, thankfully the drain plug has always been out through the years and all the core samples i drew were dry as a bone!!

7/18/2015

This picture was the plywood coated vs uncoated. We used West Systems epoxy resin 105 and fiberglassed matted one side (i can't seem to remember the weight of the glass though, but if anyone wants to know ill figure it out). The was probably the most hated part of the whole thing lol you just can't seem to get the resin off of you :x .

we first applied a liberal coat of resin and hardener to the wood, let it cure until a bit tacky and then laid the mat on and poured more resin on top, next we had to get all the air pockets out with a spiky roller type deal. And no this was not marine grade but it sure is now lol.

Test fitting the lower deck, the way this particular tracker was made, you had to use one entire width of 1/2 inch plywood plus a sliver cut from some of the transom wood. I believe they were able to put together the entire boat with 2 sheets of 1/2 inch plywood and go boat to boat with 3/4 inch plywood just for the transom that was sandwiched together with the 1/2 inch to create a 1.25 inch transom piece.

7/25/15

Progress was good to see at this point

7/26/15

All screws were stainless and bedded down with boat life.

Console isn't in the greatest condition, but the gauges work and we are not even close to being that good at fiberglassing, to make a new one!

got the carpet glued down for the main decks the same day we mounted them down.

In this picture i finally took apart the back casting deck where the seat post goes into, my dad and i were under the impression that it was just aluminum framing under it. lo and behold, its a plank of 3/4 inch wood. We replaced that with whats called Starboard. its like a plastic composite material, super strong and super heavy duty. We actually tossed up that option to replace the transom with starboard because it'll never rot out, but 6 ft by 2ft by 1.25 inch would be extremely heavy and costly.