Well, it's been a while.. between finding the time and the $ required, things have been a slow-go, but there has been

some progress.

I have managed to pick up a bunch of the things I'll be needing though. 3 "31" Batteries, on-board charger, switch panels, aerator timer, seat bases, etc.. On that note, I thought I'd mention that if you guys make a shopping list and plan on getting any of it at BPS, you can go to the store, get a BPS Visa and get 10% off your first purchase. I saved just shy of $100. (almost one of my 3 batteries free!)

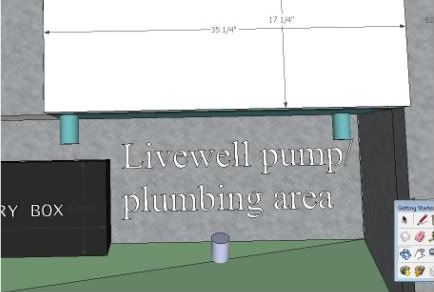

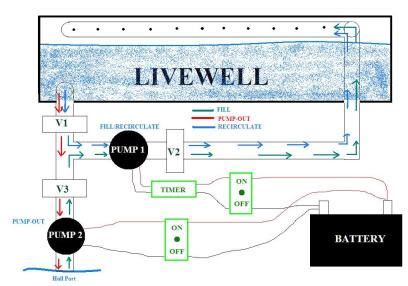

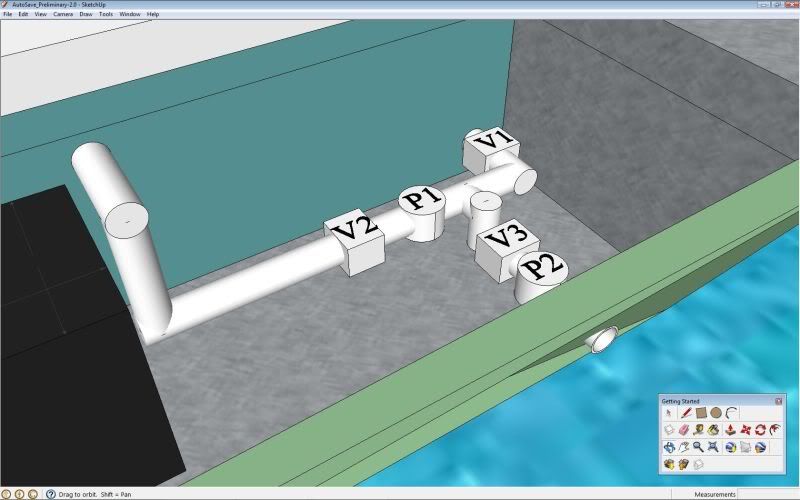

As far as the livewell thing goes, I've been working with flowRite on my design, and I'm just going to get everything I need from them. Gonna go with their system #3 and integgrate it into the 70qt cooler. Very slick system. Pump, plumbing, valve, fittings, and all hoses are estimated at $160. Will be ordering VERY soon as I need to install it before I can do a whole lot more on my framing layout.

Decking material will be Ramp Armor. It's a composite material made by Iten Ind. that's used to deck ramp surfaces in outdoor skate parks. It's UV neutralized, doesn't absorb water, and it's strong as what. I have a sample piece that's 1/4" x 8" x 12", and I can't bend it. I think 1/4" sheet will be fine, but I still might upgrade to 3/8" just to be on the safe side. I have some spans that are 16" centers. The 1/4" runs $75 per 4' x 8' sheet... Well, for me anyway. My Mother works there and they're local; I can get "2nds". =D>

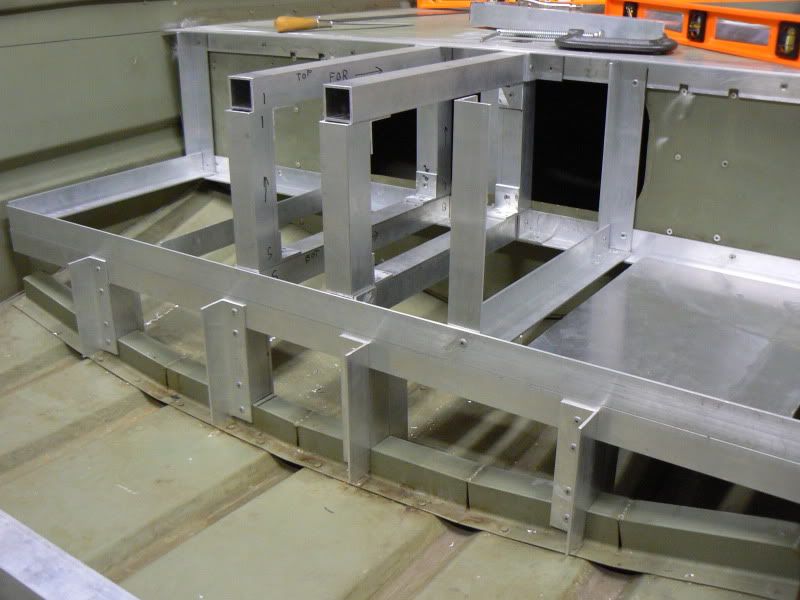

Anyway, here's where the framing is...

Bow deck seat box with tackle hatch framing on either side.. there's still some work to do on this section as there will be a battery tray on each side in front of the tackle hatches and I couldn't tie the two together until I finished my main deck.

Another of front section with extension mocked-up and in place. There will be a sq tube that drops from under this down to the main deck level. The livewell will be nestled up against the "wall" that will be created, then will be framed around at the same level as the flange that remains from the middle bench that was removed.

Main deck area showing stern seat box

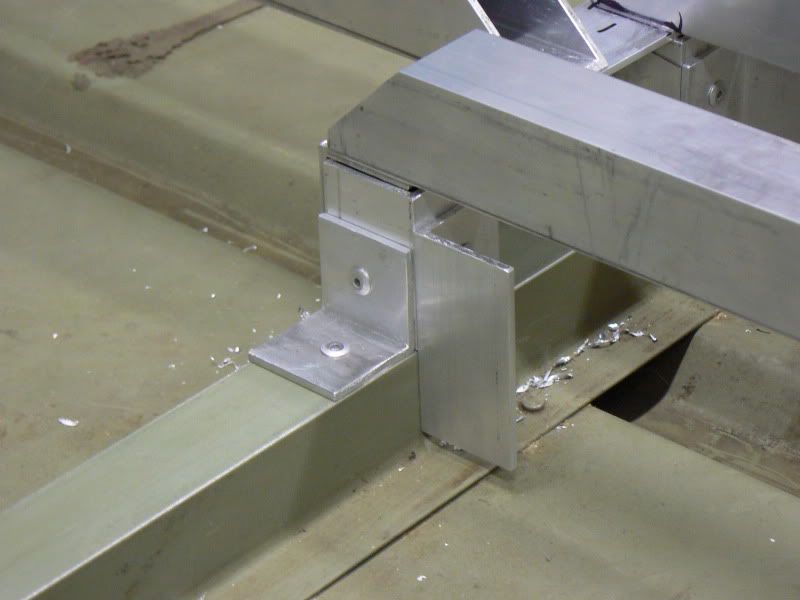

Close up of main deck seat box support

Some random thoughts..

Don't use a cut-off wheel. I thought it'd work great, but only makes a massive mess. A power miter saw with a regular carbide tipped blade works great.

When riveting, whenever possible, deburr both sides of your drilled hole. If you clamp your pieces together real tight first, the inner faces won't need it, but the entrance and exit still will.. especially the exit side. It makes the joint a lot stronger.

Even with a power miter saw, it's still very difficult to get each joint perfectly square. Cut a little long and "massage" it in where load bearing posts need good fluch contact.

Aluminum angle is not excatly 90deg. It's an acute angle. More like 87deg or so. This can impact squarenesss. Just be sure to rivet in an order that will allow your supports to remain square after fastening.

The inside corner of the angle has a small radius in it.. probably about .050" or so If you are looking for good, solid, flush contact (for ideal weight distribution maybe), be sure to break the edge of the piece that will be on the inside of the angle.

Don't just cut and start riveting. You want to basically do a complete layout, then start riveting from the inside out, otherwise, you may end up with a situation where you are unable to drill a hole for lack of drill clearance.

I'm sure most of you guys already know that stuff, I just thought I'd throw it out there in case there are more noobs like me. :wink:

Tight Lines!