novaman

Well-known member

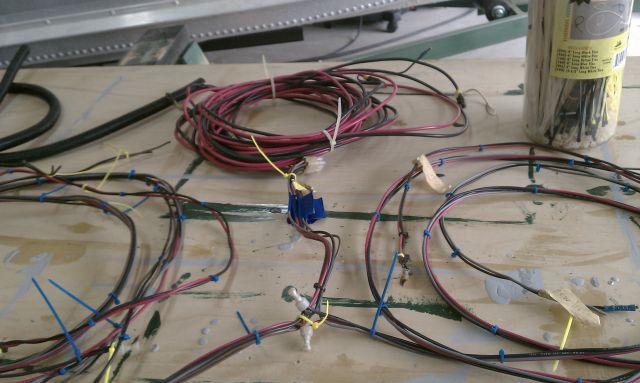

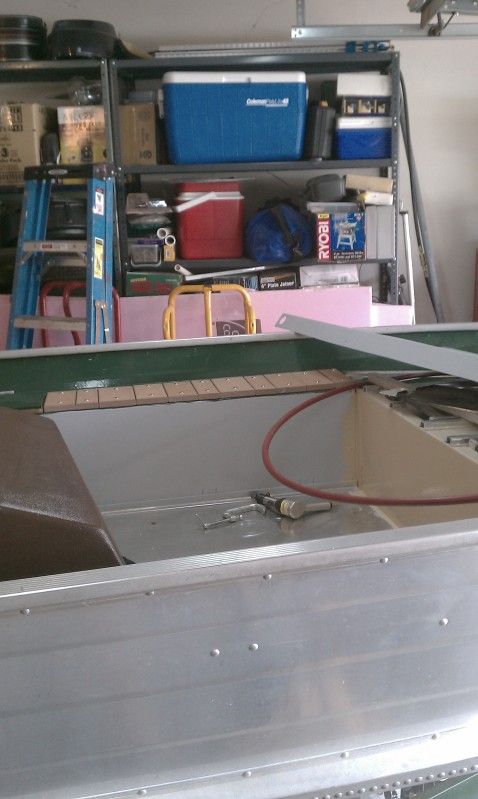

Real Nice =D> . Really fine looking conversion, can't wait to see the finished floor, since I'm just installing my floor now. You've also presented a very complete set of pics for everything done. great job 8)

novaman said:Real Nice =D> . Really fine looking conversion, can't wait to see the finished floor, since I'm just installing my floor now. You've also presented a very complete set of pics for everything done. great job 8)

Brine said:Looking good Dave.

How much does the hat channel run? What are the dimensions?

bigwave said:Very nice work Dave, I would like to know how much that cap channel cost too. =D>

fender66 said:Beautiful work. =D> =D>

DaveInGA said:That's a nice drawing. I've got some work ahead of me cutting up the big aluminum sheets I have now, then I think I'll be ready to do something about the console. I'd like a center console like the one you have drawn up, but routing the steering cable and setting the boat up for a center console would be just a bit to much work to do in my boat. Too many things would have to change that I liked about the boat.

I'm pretty sure I'm not going to use the Bass Tracker console and base I now have, so I'll likely sell that and any related parts to help offset some of the costs of making a new console. It'll make someone who is putting back in plywood floors a quick easy install.

Bugpac said:were the controls on the side of the console, or the side of the boat.

The controls were mounted on the side of the boat.

I drew this as a side console, Its to short to stand as a center I think. If you give me some dimensions and stuff I can edit and adjust.

fool4fish1226 said:Dave - The boat is coming along great keep up the the good work :beer: