TexMaid

New member

First post, been lurking for a few weeks looking through builds and getting ideas! Figured it was time to join and show what I'm working with, and also track my progress!

I picked up this little boat, motor and trailer a few weeks ago for $200, figured I couldn't pass it up for that price, and could afford to put a little money into it to make it what I want. From what I looked up on the TPWD site, it's a Texas Maid. Measures right under 14' long, and 61" across the beam at the widest point. The motor is a 1967 Johnson Seahorse 6hp, and the trailer is a homemade one. Honestly thinking of just selling the trailer for whatever I can get, and buying a new one. Also, I picked up a 1970 Evinrude 18hp last night, got it for $100 and it's in a lot better condition than the Johnson, plus I figured it would push me around quite a bit better. Can't go wrong for $100 right?

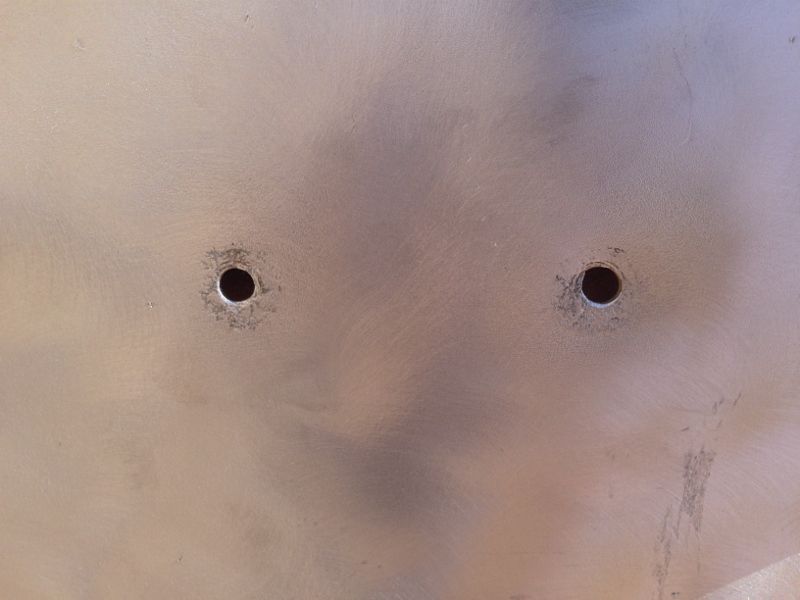

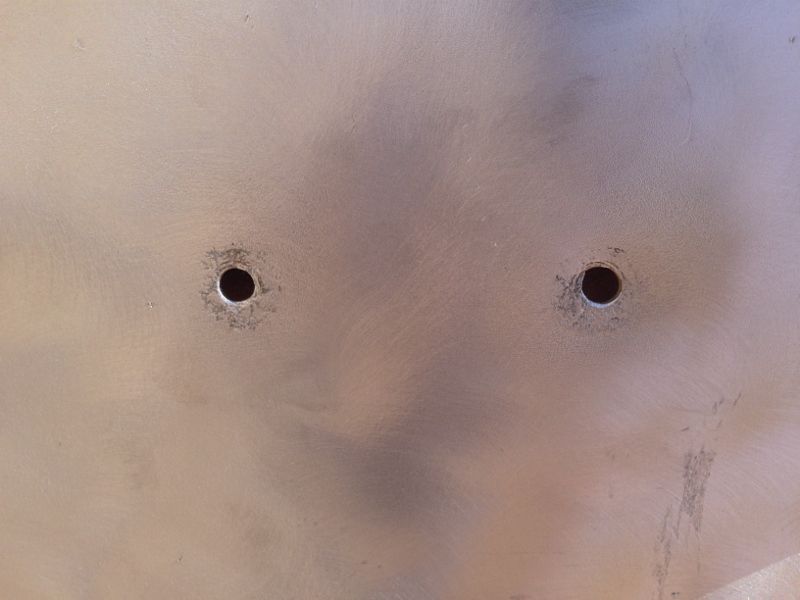

Only question I have, is what is the best way to go about replacing the transom? I could not get it out in one piece, unfortunately, so I have nothing to trace. There is also a big steel plate that was used to hold everything together, and there is some obvious places of some kind of chemical reaction between the two (see pics). This is my first boat, so honestly not too seasoned in any of this. Just going off what I've read. Oh, and also...on the bottom of the boat, there are the "fins" going across, and theres two spots where it's busted up pretty good (see pics)...what is the best way to go about fixing that?

I've wire brushed some places down...I was planning on doing the whole boat to prep for paint, but I might just switch to sanding to rough up the surface a little. I plan on painting it, I want to go with a glossy almond color, with either a deep red or deep blue strip on the top, and maybe build a carpeted floor later down the road, but for now just want to get it water worthy and go from there!

Anyway, enough talking, I have a ton more to say, but on to the pics! I'll ask more questions as they come to me.

Original pics sent to me from previous owner-

And what I've done so far...

And here's the Evinrude I picked up for $100

Let me know what y'all think guys, glad to be here!

I picked up this little boat, motor and trailer a few weeks ago for $200, figured I couldn't pass it up for that price, and could afford to put a little money into it to make it what I want. From what I looked up on the TPWD site, it's a Texas Maid. Measures right under 14' long, and 61" across the beam at the widest point. The motor is a 1967 Johnson Seahorse 6hp, and the trailer is a homemade one. Honestly thinking of just selling the trailer for whatever I can get, and buying a new one. Also, I picked up a 1970 Evinrude 18hp last night, got it for $100 and it's in a lot better condition than the Johnson, plus I figured it would push me around quite a bit better. Can't go wrong for $100 right?

Only question I have, is what is the best way to go about replacing the transom? I could not get it out in one piece, unfortunately, so I have nothing to trace. There is also a big steel plate that was used to hold everything together, and there is some obvious places of some kind of chemical reaction between the two (see pics). This is my first boat, so honestly not too seasoned in any of this. Just going off what I've read. Oh, and also...on the bottom of the boat, there are the "fins" going across, and theres two spots where it's busted up pretty good (see pics)...what is the best way to go about fixing that?

I've wire brushed some places down...I was planning on doing the whole boat to prep for paint, but I might just switch to sanding to rough up the surface a little. I plan on painting it, I want to go with a glossy almond color, with either a deep red or deep blue strip on the top, and maybe build a carpeted floor later down the road, but for now just want to get it water worthy and go from there!

Anyway, enough talking, I have a ton more to say, but on to the pics! I'll ask more questions as they come to me.

Original pics sent to me from previous owner-

And what I've done so far...

And here's the Evinrude I picked up for $100

Let me know what y'all think guys, glad to be here!