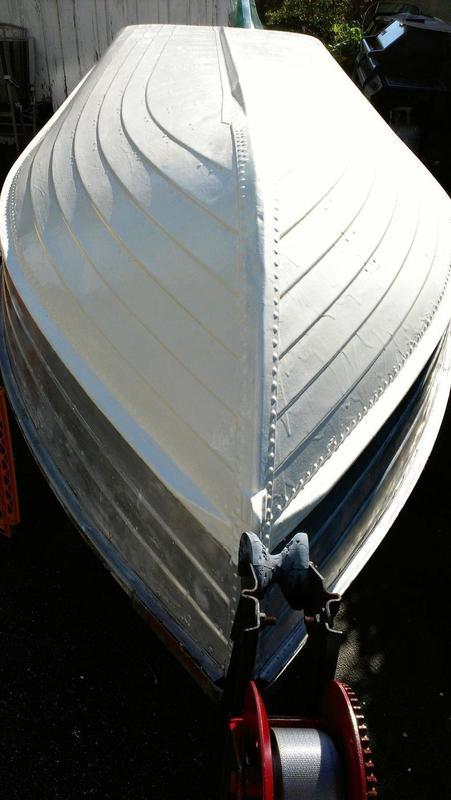

Here are some pictures of my Steel Flex application. Had one serious sag near the bow after the second coat went on. I did the two person application. I found if you want a thinner coat, it is best not to pour the steel flex and try to push it around. We had problems controlling the thickness when poured. It's best if you can dip your brushes and then apply it. Also, we felt that the foam brushes did not work as well as inexpensive paint brushes. It was much easier to move the epoxy around than the foam brushes and rollers. Only draw back was the occasional loose bristle in the paint. The temp was 82+ degrees and seemed to be a good working temperature. We only had one batch that seemed to set up too quick. The paint on the boat is Krylon Camo Flat Olive Drab, and the Steel Flex is Olive Drab as well, using all of the pigment. The color match is better than it looks in the pics. It won't be perfect because one is gloss and the other is flat. Hope this helps someone!

I have read all 23 pages of this post and have only one question. Is there any special gloves that I need to apply this stuff? I work in a hospital and can get regular medical exam gloves. Will those work?

I have read all 23 pages of this post and have only one question. Is there any special gloves that I need to apply this stuff? I work in a hospital and can get regular medical exam gloves. Will those work?