rick50

Well-known member

I read about the aluminum breaking you were trying to bend. You may know this already ,but if you get a marine type of aluminum,5356, it bends a lot easier without breaking.

WhiteMoose said:Thanks for the reply caveman. I was trying to bend the aluminum to make brackets, but decided the only thing I can do is use steel brackets. I found some nice thick steel angle brackets for about $1.50 that I should be able to bend in the bench vise. They appear to be stainless, but what if they aren't? Can I paint them to prevent rust & any bad interactions w/ the aluminum?

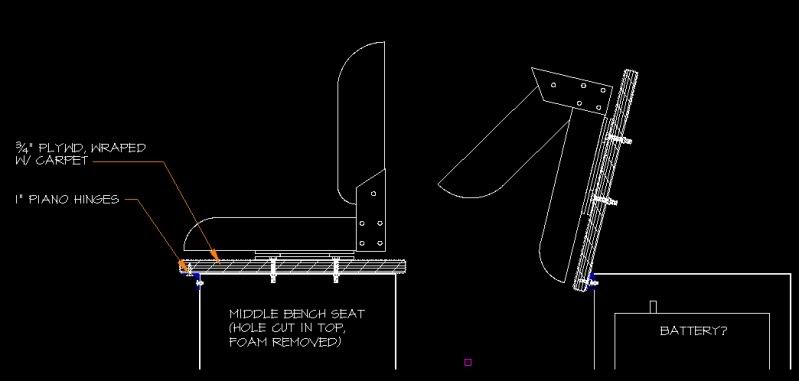

Sorry to hijack my own reply, but does anyone foresee any possible issues with this modified bench seat design? If I cut the top of the bench seat out but leave the sides, is that enough reinforcement to keep the sides of the boat from caving in or the ribs from cracking?

WhiteMoose said:This week I got my middle seat tore out and the new framing up (pictures to come). I have all my plywood cut, sanded, and waterproofed, but I ran out of carpet! I used Lowes marine carpet. The kid at the counter said I have to order a minimum of like 30 feet, but I only need 6 more feet, so I'm trying to decide what to do. 30 feet of that carpet will cost around $160, which is more then I've spent on any part of this boat, other than the boat itself. :x