CMOS

Well-known member

Howdy All,

I've been working on this motor for a few months and finally got her fired up in the driveway last weekend. This weekend (Labor Day) was supposed to be its maiden voyage. Lady Luck was not having any of that however. We never got away from the dock. Hoping for some help with a few things I will need to to.

Problem #1 at the boat ramp: When priming the bulb I saw fuel pouring out of the rear part of the lower cowling (float issue I'm betting). I did do a full carb kit in this carb myself, so the leaking fuel was a surprise.

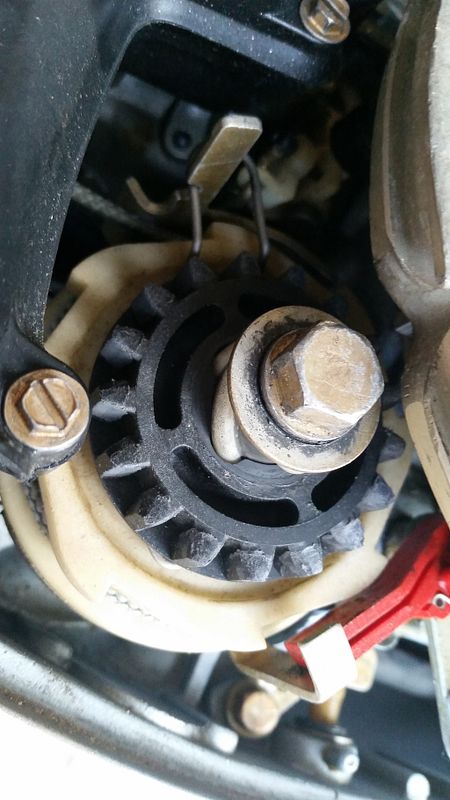

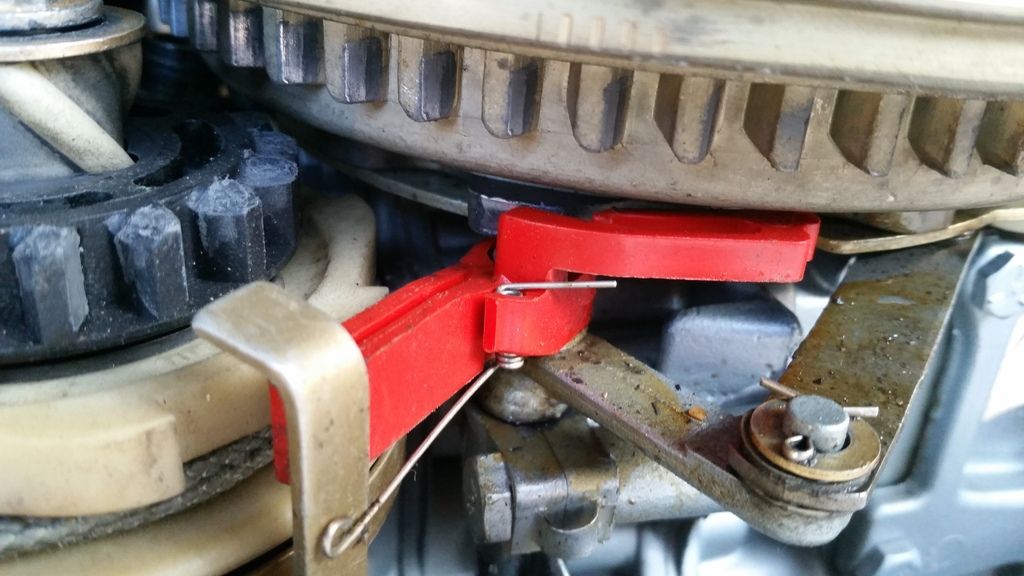

Problem #2: I was able to get it started but the idle never did get up to an RPM that was sustainable without me having to slightly advance the throttle. Engine finally died. Could not get it to restart again. However, a secondary and more pressing issue is that I'm having problems with the recoil starter in that there is a red colored "arm" that keeps engaging the starter gear that stops the pull cord from coming out. I now have a sprained wrist due to this. When I try to pull the cord (yes, in NEUTRAL) the cord will come out maybe 1/4 or 1/3 of the way then dead STOP and lock. It's the red arm thingy (darned if I could find what this part is called on Boats.net or my service manual.) I also need to replace the recoil spring as the cord does not retract all the way. So - how do I 1) replace the recoil spring and how do I keep that red arm thingy from engaging the starter gear? See attached pic.

I tried to restart the motor in the driveway after the failure at the lake. I could not reproduce the leaking fuel at this time, however I still plan to pull and check the carb after I get the starter issue resolved.

Thanks for any guidance on this.

CMOS

I've been working on this motor for a few months and finally got her fired up in the driveway last weekend. This weekend (Labor Day) was supposed to be its maiden voyage. Lady Luck was not having any of that however. We never got away from the dock. Hoping for some help with a few things I will need to to.

Problem #1 at the boat ramp: When priming the bulb I saw fuel pouring out of the rear part of the lower cowling (float issue I'm betting). I did do a full carb kit in this carb myself, so the leaking fuel was a surprise.

Problem #2: I was able to get it started but the idle never did get up to an RPM that was sustainable without me having to slightly advance the throttle. Engine finally died. Could not get it to restart again. However, a secondary and more pressing issue is that I'm having problems with the recoil starter in that there is a red colored "arm" that keeps engaging the starter gear that stops the pull cord from coming out. I now have a sprained wrist due to this. When I try to pull the cord (yes, in NEUTRAL) the cord will come out maybe 1/4 or 1/3 of the way then dead STOP and lock. It's the red arm thingy (darned if I could find what this part is called on Boats.net or my service manual.) I also need to replace the recoil spring as the cord does not retract all the way. So - how do I 1) replace the recoil spring and how do I keep that red arm thingy from engaging the starter gear? See attached pic.

I tried to restart the motor in the driveway after the failure at the lake. I could not reproduce the leaking fuel at this time, however I still plan to pull and check the carb after I get the starter issue resolved.

Thanks for any guidance on this.

CMOS