First off I would like to say thanks to the Tinboats forums. A lot of really cool projects on here and great ideas from people all over about how to build out our tin boats. The boat I have has been in our family since new in 1976. My dad got it from my step mom's dad back in 92 or 93 and we had a little 9.8 Mercury on it and a small 32 lb thrust transom trolling motor, no depth finder, straight stock bench seating, just as you would expect an old 14 foot Lund to be. A few years after we got the boat the motor seized up and the boat sat in the back yard for a couple years. After I got my driver's license my dad told me that if I bought a motor I could have the boat, so I saved all summer and picked up a 15 horse Mariner. Dad kept true and gave me the boat and I was fishin.

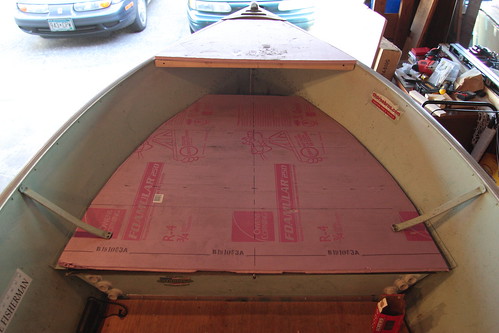

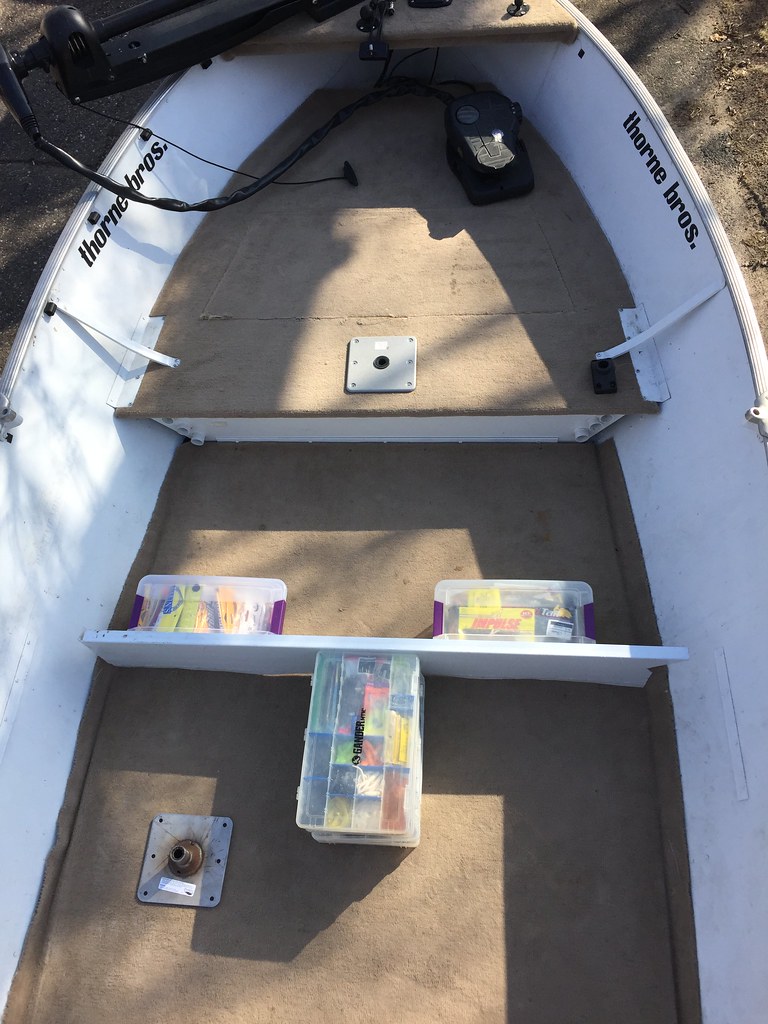

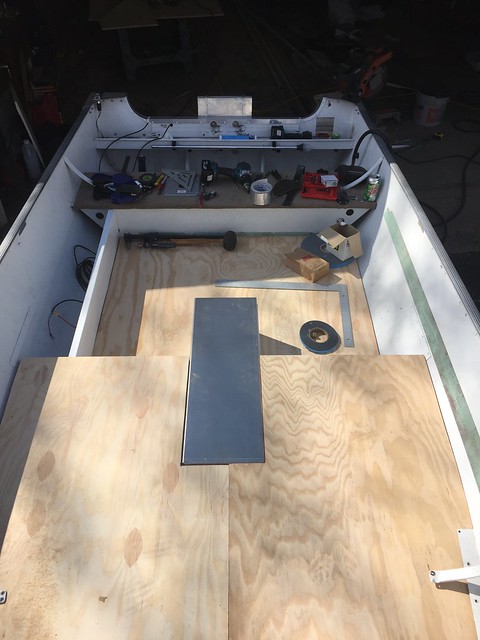

Fast forward a few years and a few beers and my buddy and I got the idea to rip out the middle bench and install a plywood floor in the center section of the boat. Out came the sawzall and that was that. I took the middle bench down about 6 1/2" below the top of the bench and then formed a 1" return on the top of both bench supports. This acted both as support for the floor as well as keeping the structural rigidity of the boat as best as possible. I also cut holes in the front bench and put PVC tubes through it for rod tubes. This worked pretty well and kept the tips of the rods down while traveling down the road while the reel weighed down the butt end, never lost a rod running down the highway like this.

Flat plywood floor circa 2007

Rod tubes

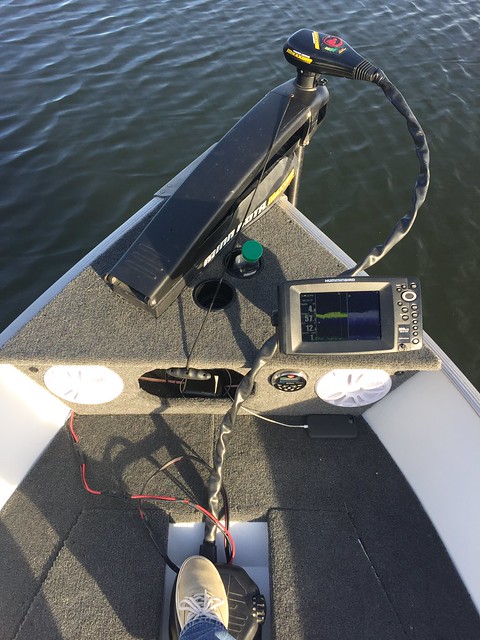

The old Mariner 15 would push the boat about 22-23 mph in this configuration, pretty decent clip across the water.

I remodeled the boat again a few years later in 2010. I will go thru that one in the next post. I am now in the process of my third remodel project and this is the biggest and most involved by far.

Thanks for reading,

Tom

Fast forward a few years and a few beers and my buddy and I got the idea to rip out the middle bench and install a plywood floor in the center section of the boat. Out came the sawzall and that was that. I took the middle bench down about 6 1/2" below the top of the bench and then formed a 1" return on the top of both bench supports. This acted both as support for the floor as well as keeping the structural rigidity of the boat as best as possible. I also cut holes in the front bench and put PVC tubes through it for rod tubes. This worked pretty well and kept the tips of the rods down while traveling down the road while the reel weighed down the butt end, never lost a rod running down the highway like this.

Flat plywood floor circa 2007

Rod tubes

The old Mariner 15 would push the boat about 22-23 mph in this configuration, pretty decent clip across the water.

I remodeled the boat again a few years later in 2010. I will go thru that one in the next post. I am now in the process of my third remodel project and this is the biggest and most involved by far.

Thanks for reading,

Tom