You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rivet size

- Thread starter beagler1

- Start date

Help Support TinBoats.net:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

onthewater102

Well-known member

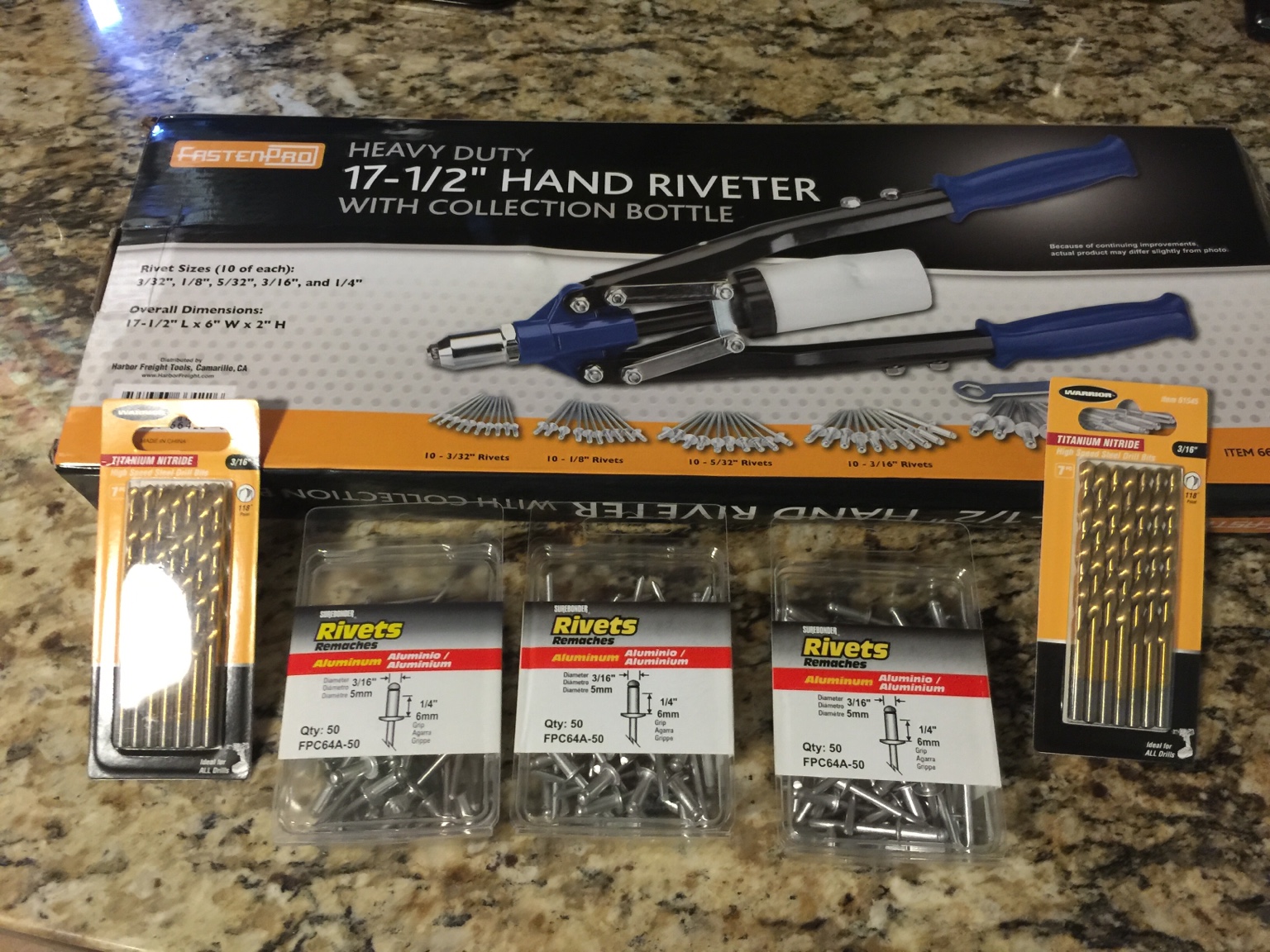

Got enough drill bits????

Those are the aluminum/aluminum rivets I was speaking of earlier.

Those are the aluminum/aluminum rivets I was speaking of earlier.

I find that by "sneaking up on the torque" (actually breaking point) on those aluminum body/aluminum mandrel rivets, rather than setting them FAST ... that one can get them pretty darn tight. They do not replace solid rivets by any means, but should be fine for sub-structure installs. FYI, on that Aircraft Spruce website, there's some guidance on the number of rivets per inch to hold the material used as needed for the designed sheer stress rating.

yup got the rivets from tractor supply!! Figure if i break a drill bit id be pissed to go buy one cause i live in the woods and have to "travel into town" just to get anything lol.onthewater102 said:Got enough drill bits????

Those are the aluminum/aluminum rivets I was speaking of earlier.

Then if i break that many bits i rekon ill be pretty pissed off lol

Sent from Mossy Oak Swamp Bottom

DaleH said:I find that by "sneaking up on the torque" (actually breaking point) on those aluminum body/aluminum mandrel rivets, rather than setting them FAST ... that one can get them pretty darn tight. They do not replace solid rivets by any means, but should be fine for sub-structure installs. FYI, on that Aircraft Spruce website, there's some guidance on the number of rivets per inch to hold the material used as needed for the designed sheer stress rating.

You mean going nice and slow before it pops?

Sent from Mossy Oak Swamp Bottom

onthewater102

Well-known member

I was using the squeeze riveter - not the two handed tool, perhaps that influenced my results.

$23.89 ($23.89 / Count)

$26.88 ($26.88 / Count)

First-Aid-Kit-for-Car-Home-Travel-Camping-Businesses, 263pcs Compact Waterproof Hard Case, Public Emergency All Purpose Medical Kits - Perfect for Survival, Vehicles, Boat, Sports, Hiking (PUMIER)

Pumier Medical

$39.91 ($39.91 / Count)

$65.98 ($65.98 / Count)

Poygik Premium 420 Piece Large First Aid Kit for Home, Car, Travel, Camping, Truck, Hiking, Sports, Office, Vehicle & Outdoor Emergencies - Emergency Medical Kits, Businesses & Home Medical Supplies

POYGIK

$26.99

$29.99

Calamus Fishing Tackle Bags - Fishing Bags for Saltwater or Freshwater Fishing - Rip-Stop PE - Padded Shoulder Strap - Pliers Storage -Green

Landon Technology

$104.98 ($104.98 / Count)

Ever-Ready Industries Premium Trauma First Aid Kit for Outdoors, Workplace, and Home - Exceed OSHA Guidelines and ANSI 2009 Standards - 240 Pieces - Includes Bonus Travel Kit

EVER-READY INDUSTRIES

$42.83

$47.79

STAR BRITE Telescopic Floating Extend-A-Brush Quick-Connect Handle with Boat Hook Attachment, 3'-6' (040054)

Amazon.com

$45.99 ($0.14 / Count)

$49.99 ($0.15 / Count)

330 Piece First Aid Kit, Premium Waterproof Compact Trauma Medical Kits for Any Emergencies, Ideal for Home, Office, Car, Travel, Outdoor, Camping, Hiking, Boating (Red)

THRIAID

$44.88

$49.99

Plano Angled Tackle System with Three 3560 Stowaway Boxes, Fishing Tackle Storage, Premium Tackle Storage

Amazon.com

$61.67

Seachoice Sterling Series Boat Cover, Water Resistant, 14-18 Ft., Fish and Ski Boat

Autoplicity ✅

$29.39

$34.59

Seachoice Cast Aluminum “S” Dock Cleat, Corrosion Resistant Aluminum, 12 in.

Amazon.com

$36.68

$41.94

Attwood NV3012SSR-7 LightArmor 2-Mile Vertical Surface Mount Navigation Light, Red LED Lighting, Round Stainless Housing

Amazon.com

THIS ... snug, then re-gripping or 'choking up on it' a couple times! Maybe its keeping the toolhead only a 1/16" or so from the pull that makes it tighter, i.e., less shaft under tension? But I find it works!Shaugh said:I seem to get the best results when I tighten the rivet just snug first, then open the gun and re-grip for the final slow pull. Don't be in a hurry. Going slow helps get them tight as possible.

Similar threads

- Replies

- 19

- Views

- 3K

- Replies

- 5

- Views

- 1K