russ010

Well-known member

Got a little more done tonight... but I ran into a few problems. When I first got the boat last year I got this real plush marine carpet from Lowe's that they had in the store. Well, I went back tonight to get some more. Figured I'd check the one closest to the house first, but they didn't have anytihng. So I drove to the next one (8 miles down the road) to where I bought it the first time - they sold out 6 months ago and haven't got any back in and don't expect to get any more. They had it in black, but that gets to hot (I'm figuring anyways) and it would show all the mud and dirt a lot more, so I went back to the standard stuff they have. Looks better than what I thought it would next to the good stuff.

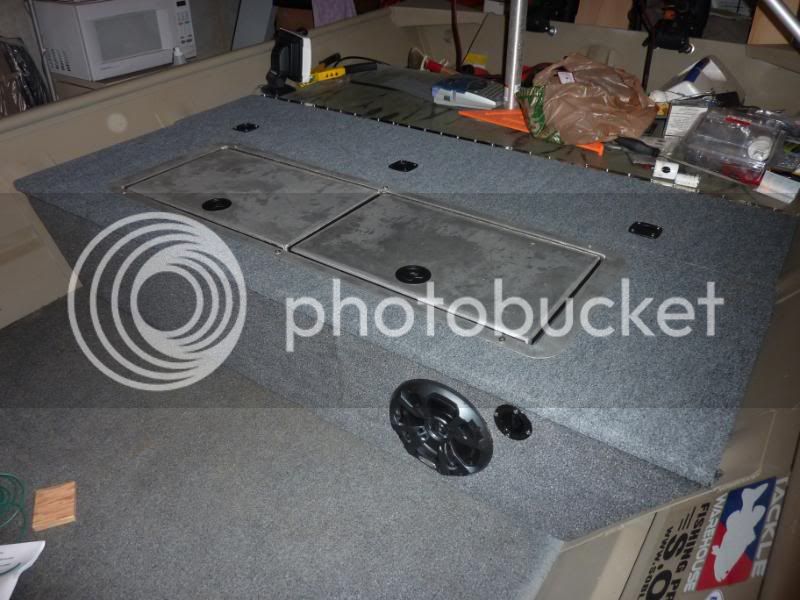

I got all the carpeting done except for one lid... and wouldn't ya know - I ran out of staples. Oh well... I did get the 2 outer lids attached. This time I did the piano hinges a little different. I attached them to the rear bench - main reason because I didn't want them to open up a full 180 degrees. I wanted to open them up because I plan on fabricating some of those "cook's tackle system" things. I'm going to cover the bench with the other roll of Hydro Turf I have left over. I was going to carpet, but I like this stuff. I wanted to do the decks and all with it, but I didn't know how to do the lid edges, and I didn't want to cut and attach them because I want my lids to be tight and I can see that stuff peeling off with the abuse.

Then I got to playing around with the livewell a little more. I got my flow rite thru hull fittings and all, and figured I'd do that since i was at a stand still with everything else. I cut the hole on the livewell for the drain. The white stuff you see is this stuff called Aqua Mend. It's the epoxy that comes in a tube, you knead it up and then apply it. A little over 60 minutes and it was cured. I swore that I would never use that 5300 stuff again because of the mess it makes. Only problem I have now is that if I ever have to change anything, I'll have to grind this stuff off with my side grinder. I wish I would have gotten a new livewell pump, but this one works still and I'll deal with that whenever it dies.

Here is the 90* drain plug on the bottom of the livewell. Then on the inside, I have these little plugs that fit into it and seals everything up.

Then it was time to cut the drain... yea, I screwed up. I should have cut it about 1/2" lower, but there should be enough pressure to drain it out.. the drain is just a little higher then the 90* bend under the livewell. I already had the hole cut, so there was no turning back.

We're supposed to get about 3-4 days of rain starting tomorrow night... so I've got a pretty good bit done considering our tourney is this Saturday. I've still got to put the fitting for the fill in the livewell, and that's pretty much it. I've got a pretty good idea for how to mount the switches, so I'll try to get all that wired up too. I'm waiting on a package from BluewaterLED, then I can really move on and start screwing everything down in place. the only thing that is set right now are the lids and the middle support brace that the lids rest on.

I got all the carpeting done except for one lid... and wouldn't ya know - I ran out of staples. Oh well... I did get the 2 outer lids attached. This time I did the piano hinges a little different. I attached them to the rear bench - main reason because I didn't want them to open up a full 180 degrees. I wanted to open them up because I plan on fabricating some of those "cook's tackle system" things. I'm going to cover the bench with the other roll of Hydro Turf I have left over. I was going to carpet, but I like this stuff. I wanted to do the decks and all with it, but I didn't know how to do the lid edges, and I didn't want to cut and attach them because I want my lids to be tight and I can see that stuff peeling off with the abuse.

Then I got to playing around with the livewell a little more. I got my flow rite thru hull fittings and all, and figured I'd do that since i was at a stand still with everything else. I cut the hole on the livewell for the drain. The white stuff you see is this stuff called Aqua Mend. It's the epoxy that comes in a tube, you knead it up and then apply it. A little over 60 minutes and it was cured. I swore that I would never use that 5300 stuff again because of the mess it makes. Only problem I have now is that if I ever have to change anything, I'll have to grind this stuff off with my side grinder. I wish I would have gotten a new livewell pump, but this one works still and I'll deal with that whenever it dies.

Here is the 90* drain plug on the bottom of the livewell. Then on the inside, I have these little plugs that fit into it and seals everything up.

Then it was time to cut the drain... yea, I screwed up. I should have cut it about 1/2" lower, but there should be enough pressure to drain it out.. the drain is just a little higher then the 90* bend under the livewell. I already had the hole cut, so there was no turning back.

We're supposed to get about 3-4 days of rain starting tomorrow night... so I've got a pretty good bit done considering our tourney is this Saturday. I've still got to put the fitting for the fill in the livewell, and that's pretty much it. I've got a pretty good idea for how to mount the switches, so I'll try to get all that wired up too. I'm waiting on a package from BluewaterLED, then I can really move on and start screwing everything down in place. the only thing that is set right now are the lids and the middle support brace that the lids rest on.