Ok so today’s adventures ... had foot surgery on one foot and then shots in the other .... so I was glad to sit down at the table and weld all afternoon [emoji3]

I decided his morning to tackle the battery box issue and boy did I ever [emoji3]

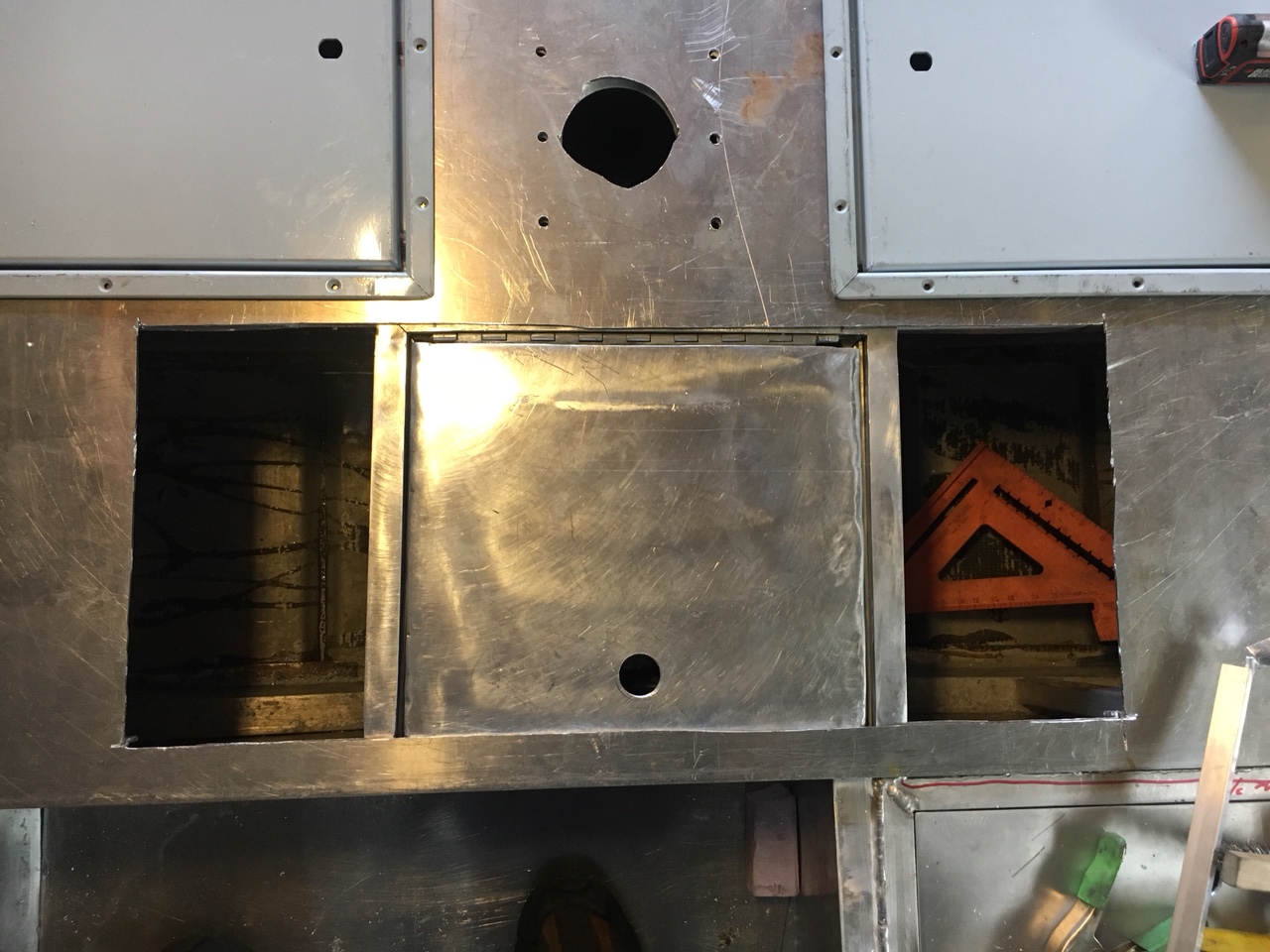

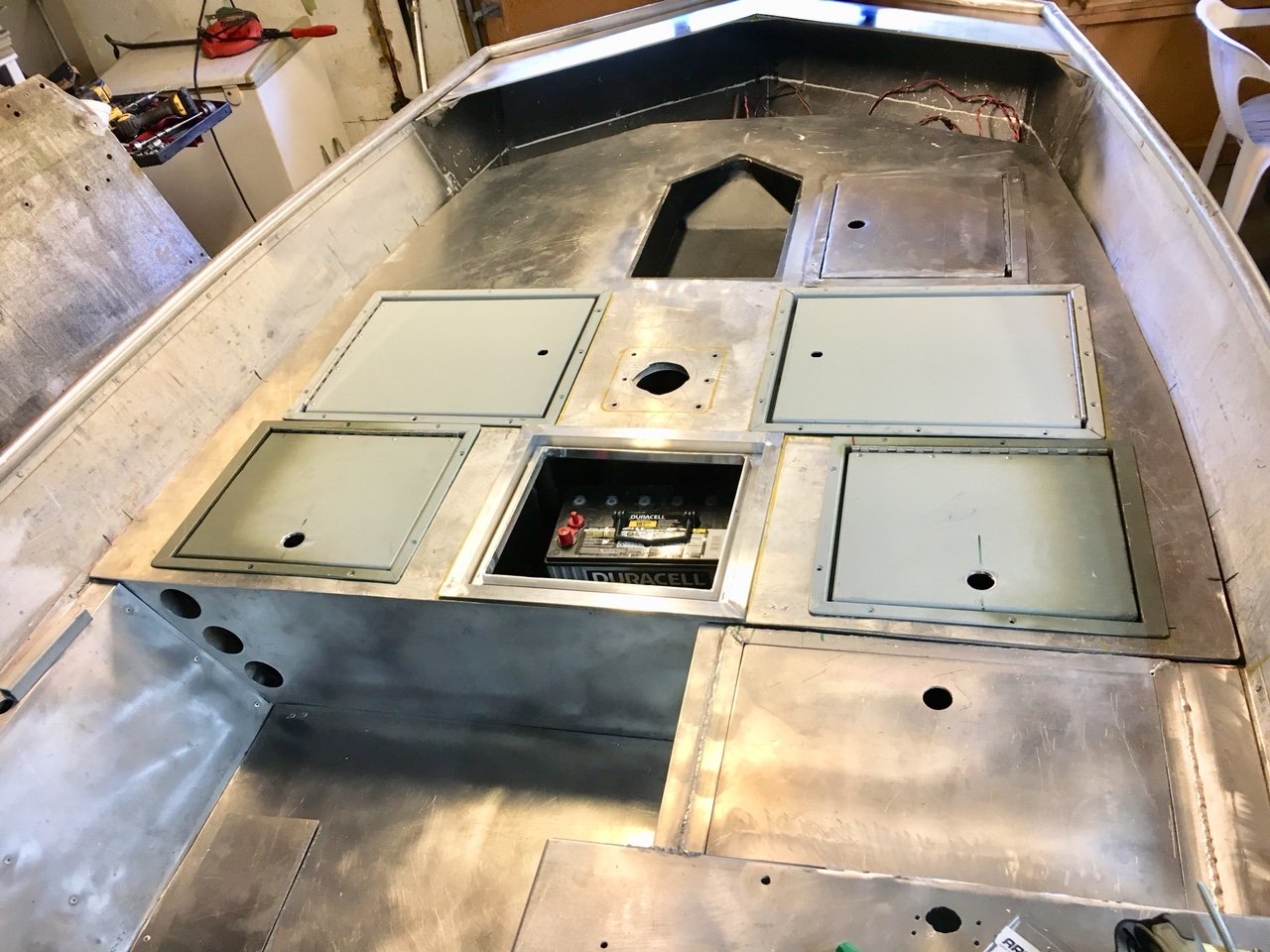

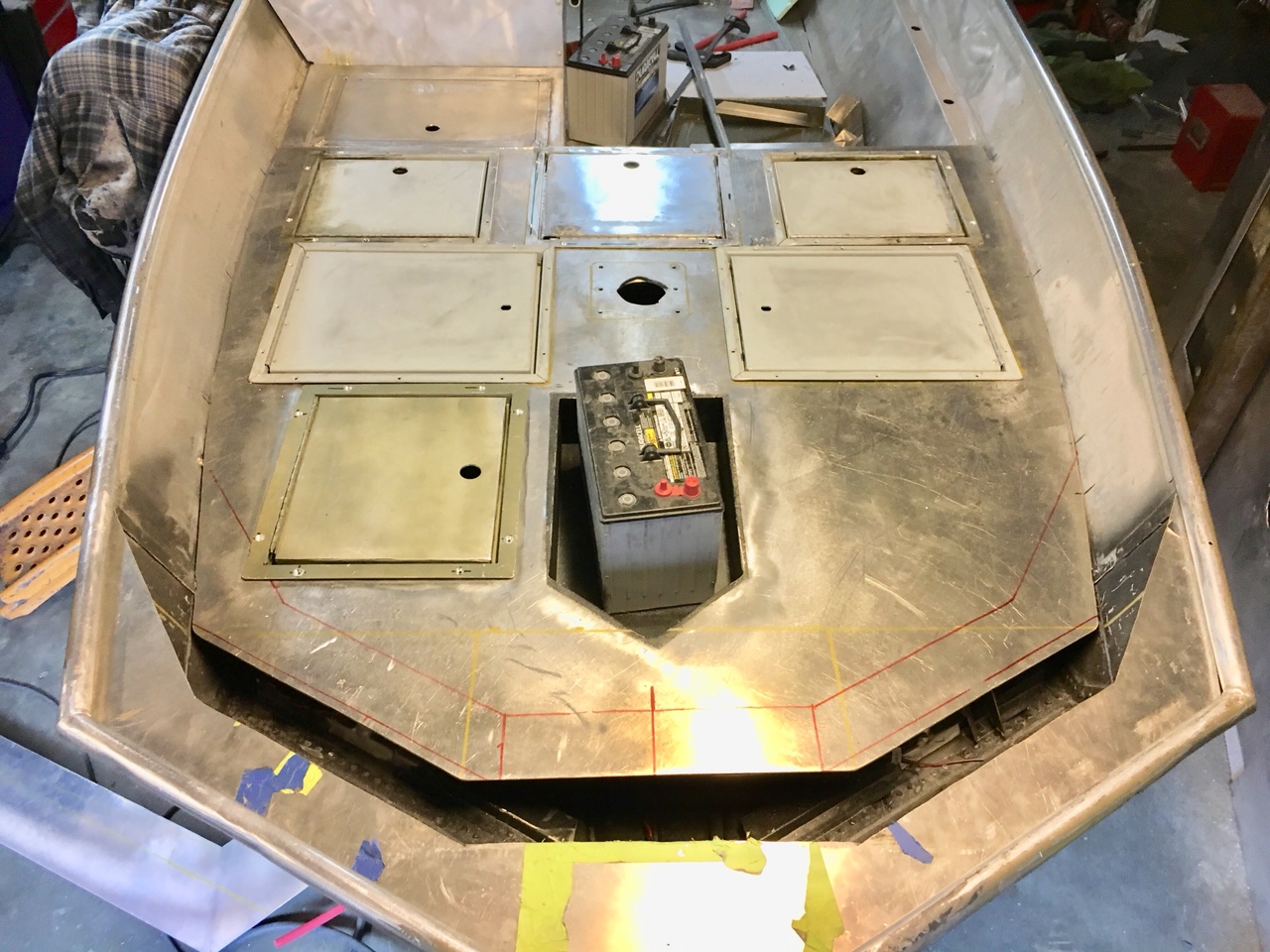

I decided to use a smaller door for the TM battery tray compartment . I removed the hold down system, rotated the batteries “sideways” in the hull and using the anchor locker door I made (which fit perfectly with just a little tweaking) decided to go for it and fill in the panels on the main deck and start over there [emoji3]

Door installed over the batteries with deck removed. Pop riveted the door in place temporarily to see how everything “worked” and made sure the batteries would actually come out if needed at a later date (that woulda sucked later if they wouldn’t come out LOL)

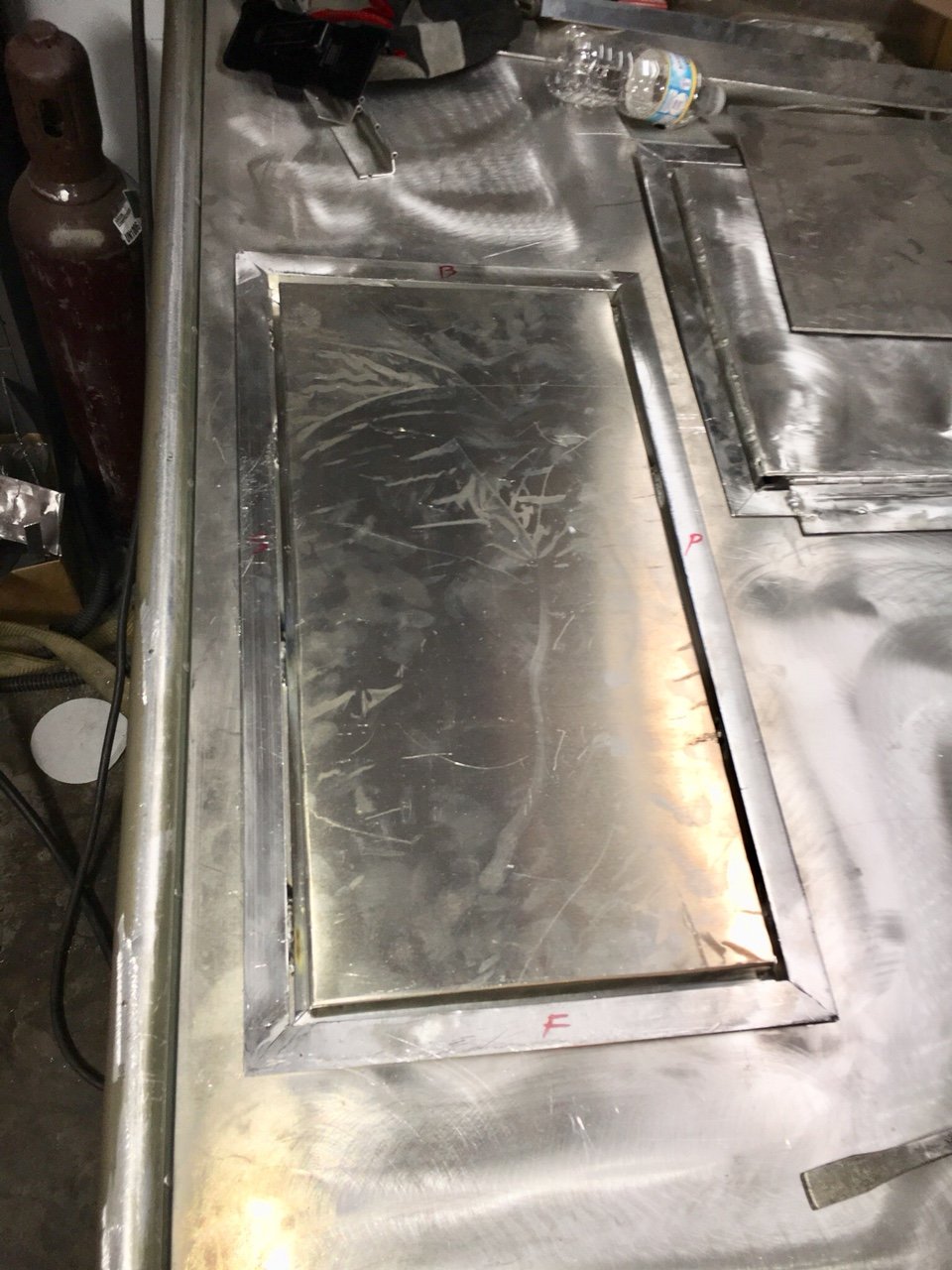

Placed the deck back in place and marked the area of the door access hole with the other doors installed to make sure everything fits at the same time.

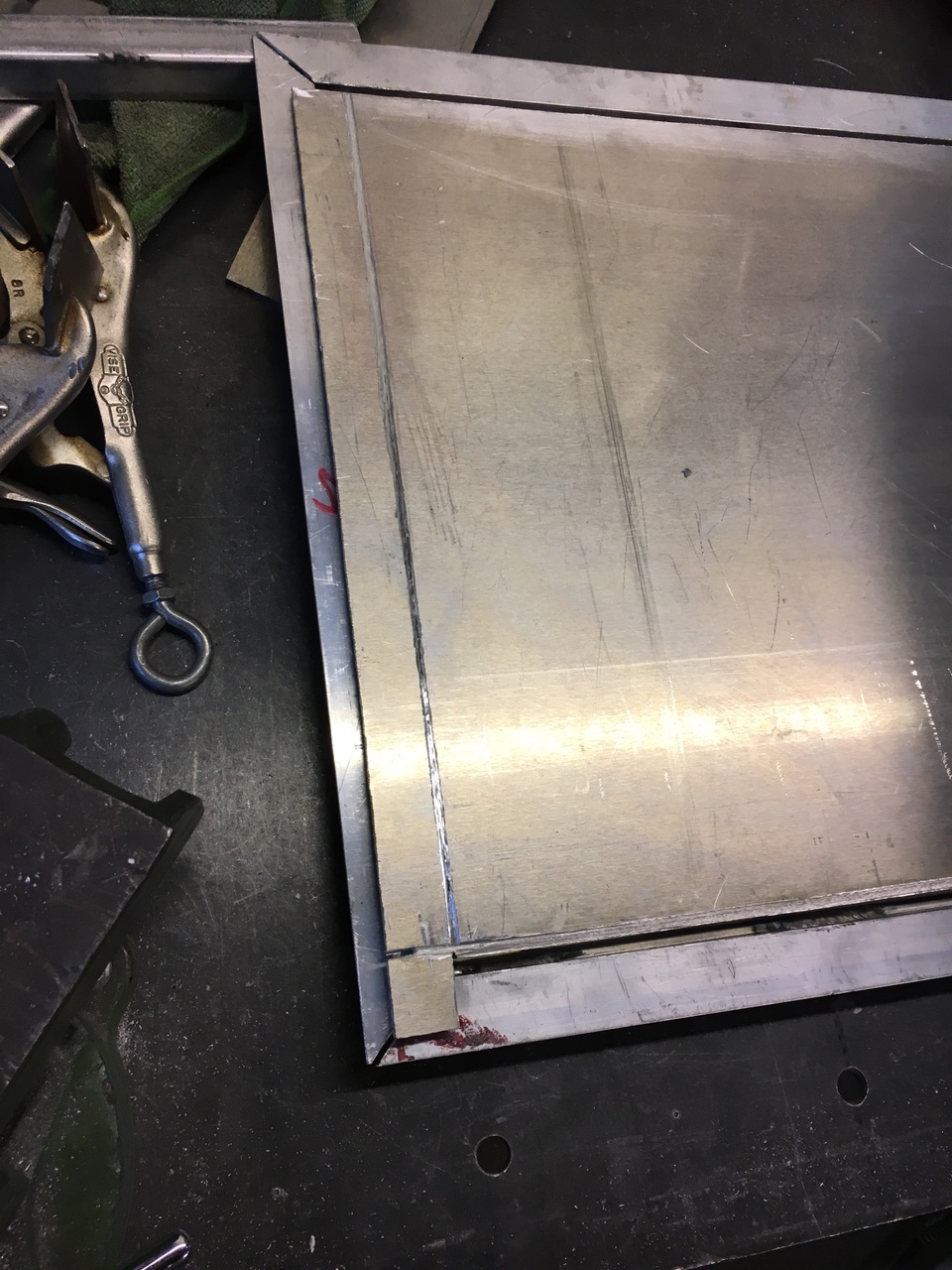

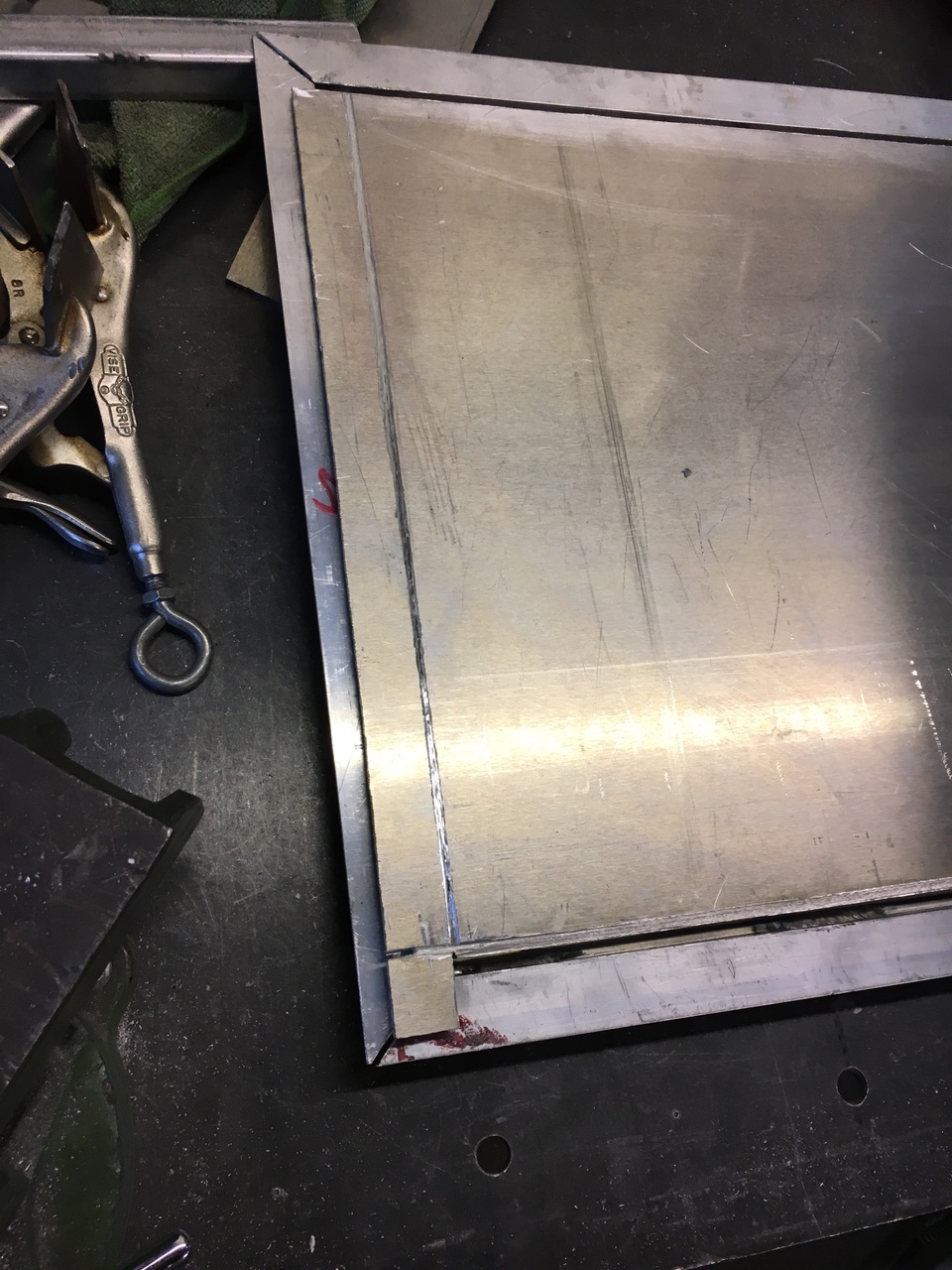

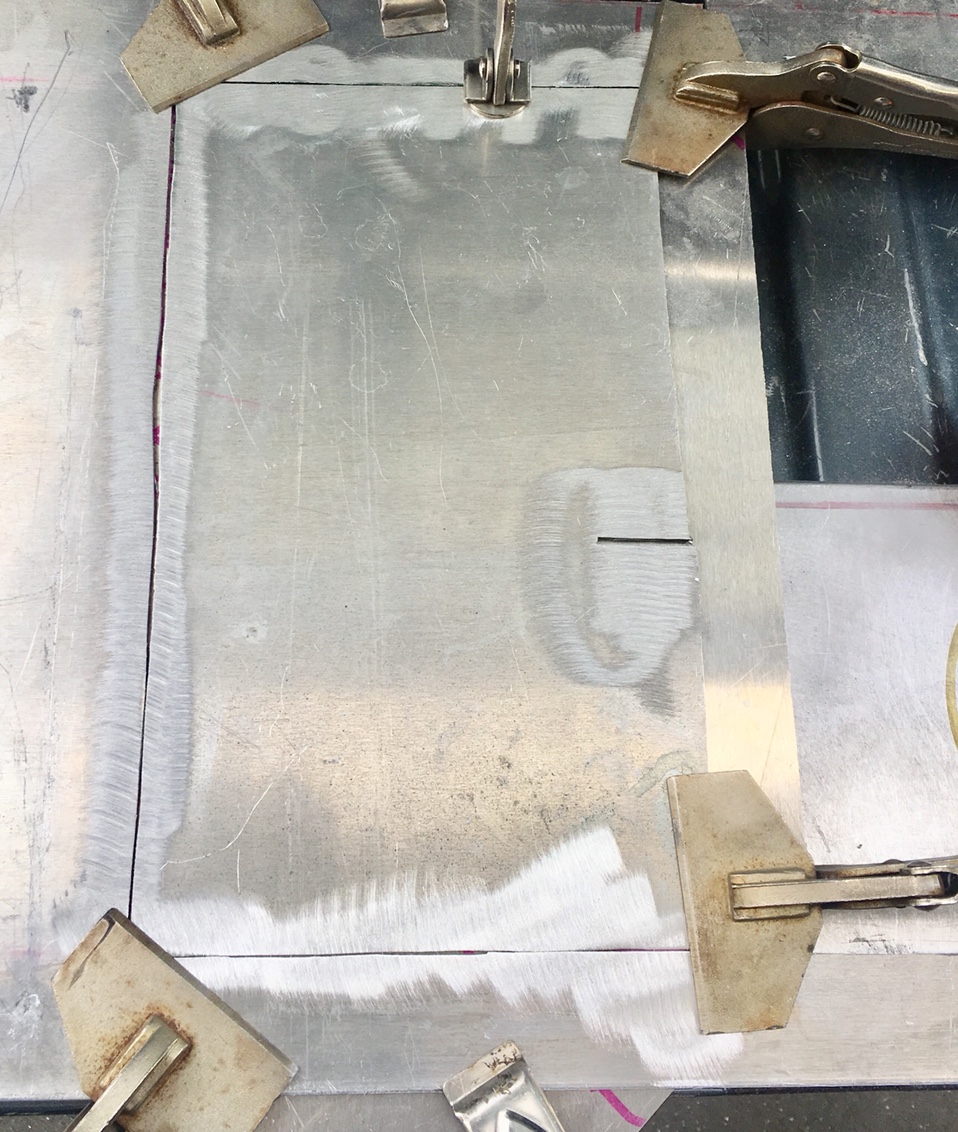

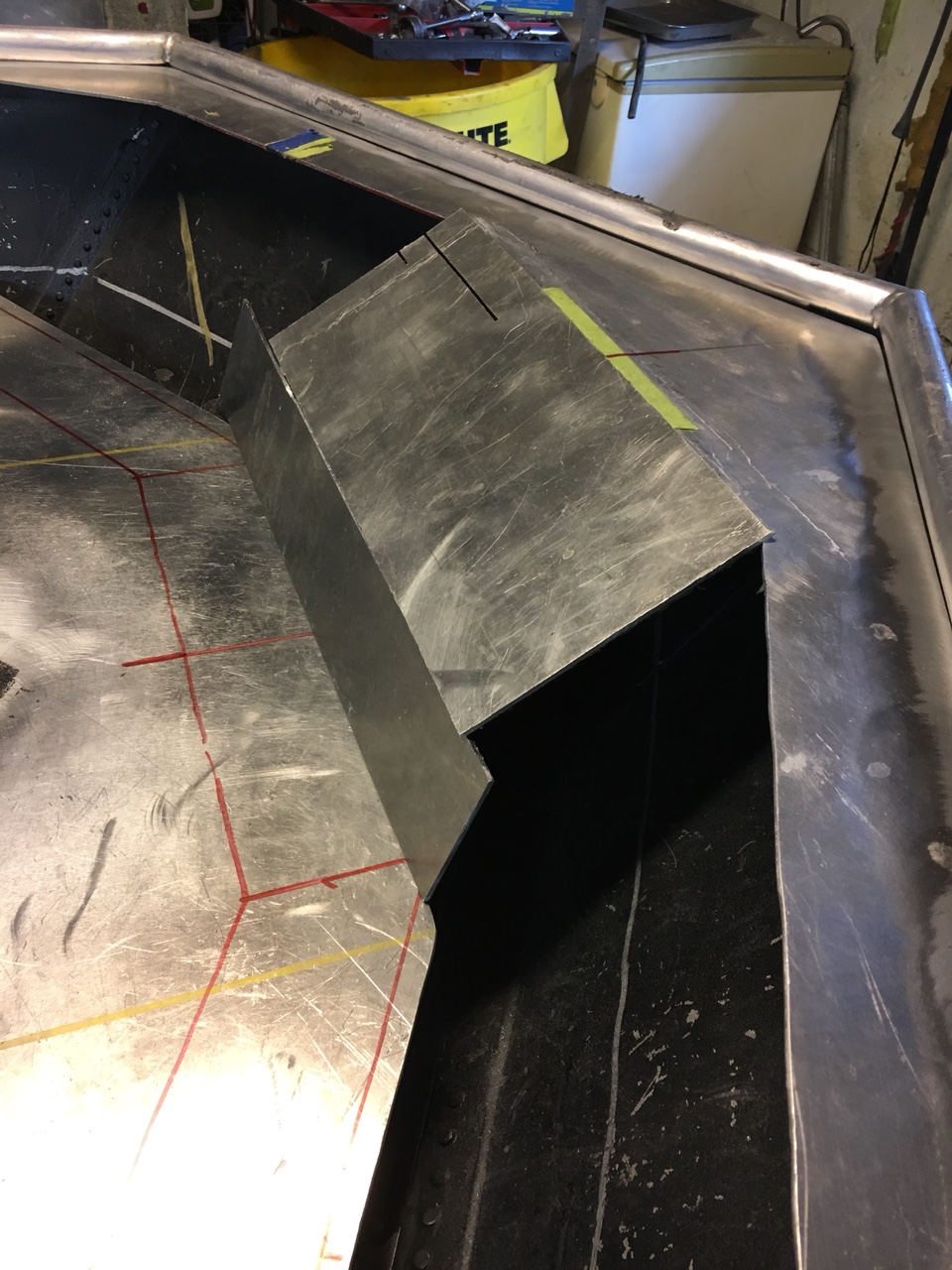

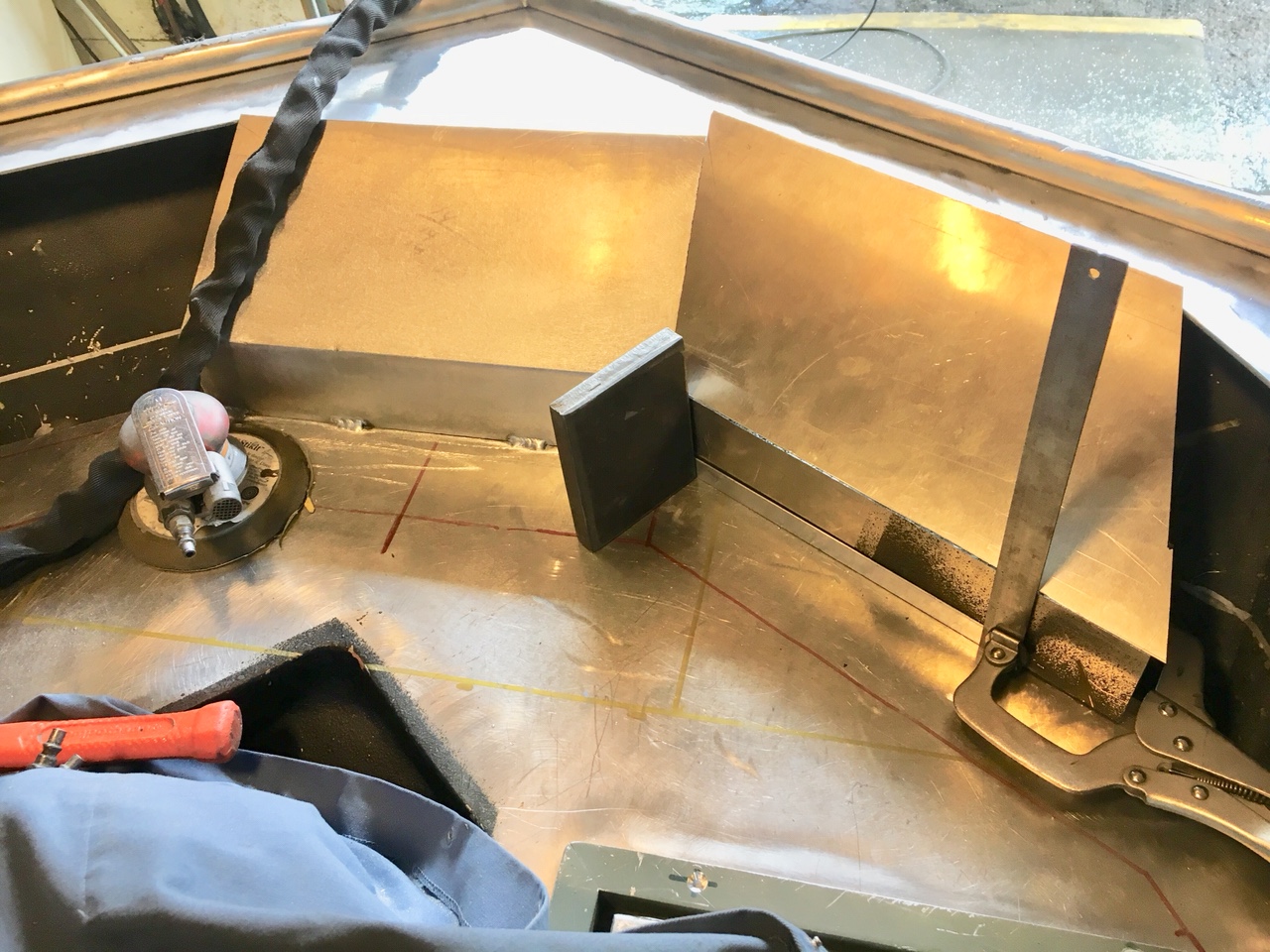

Using my table on one half and my truck tailgate on the other half of the deck I rough fit 2 scrap panels to fill in the sides to make the hole smaller.

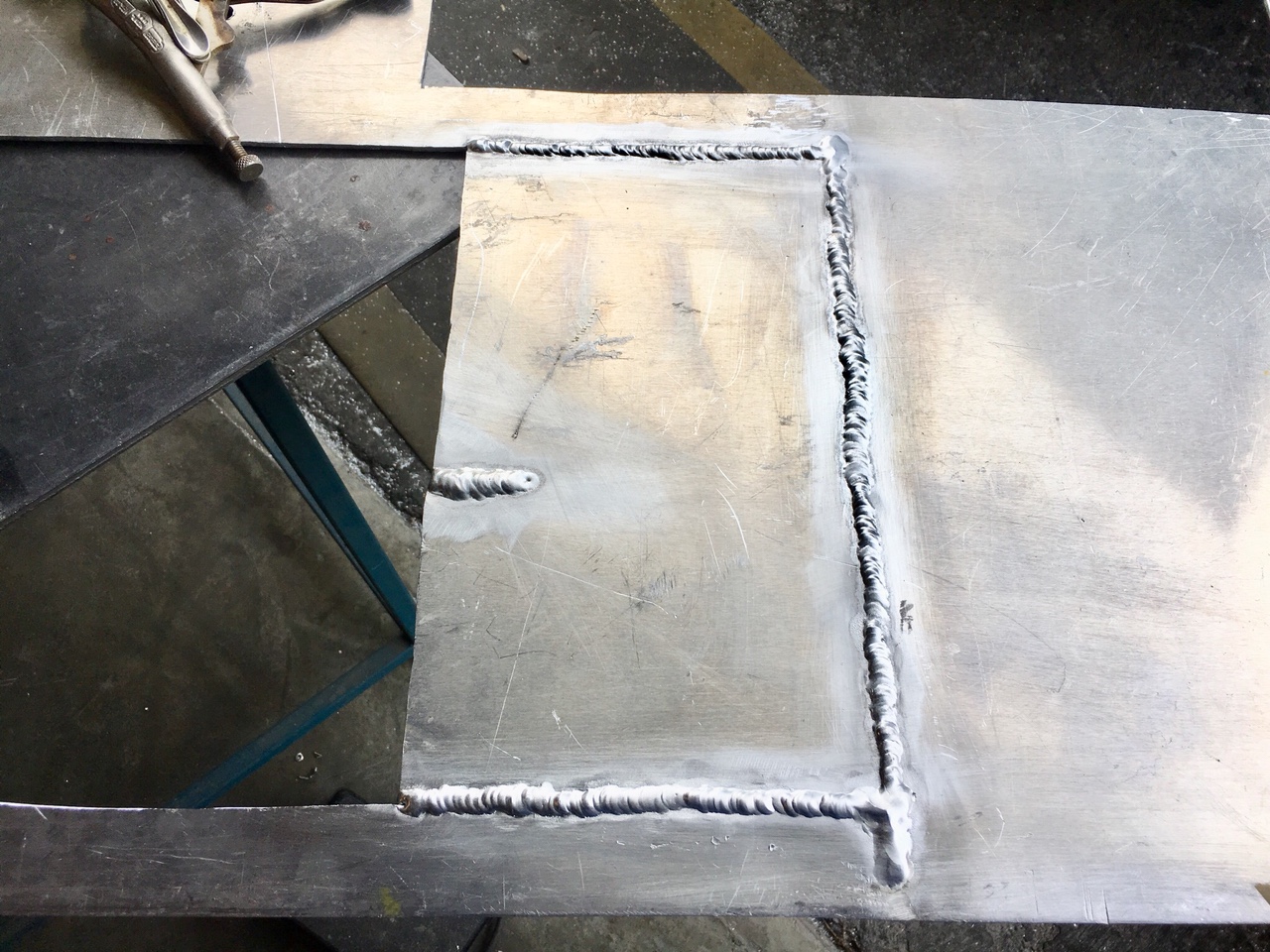

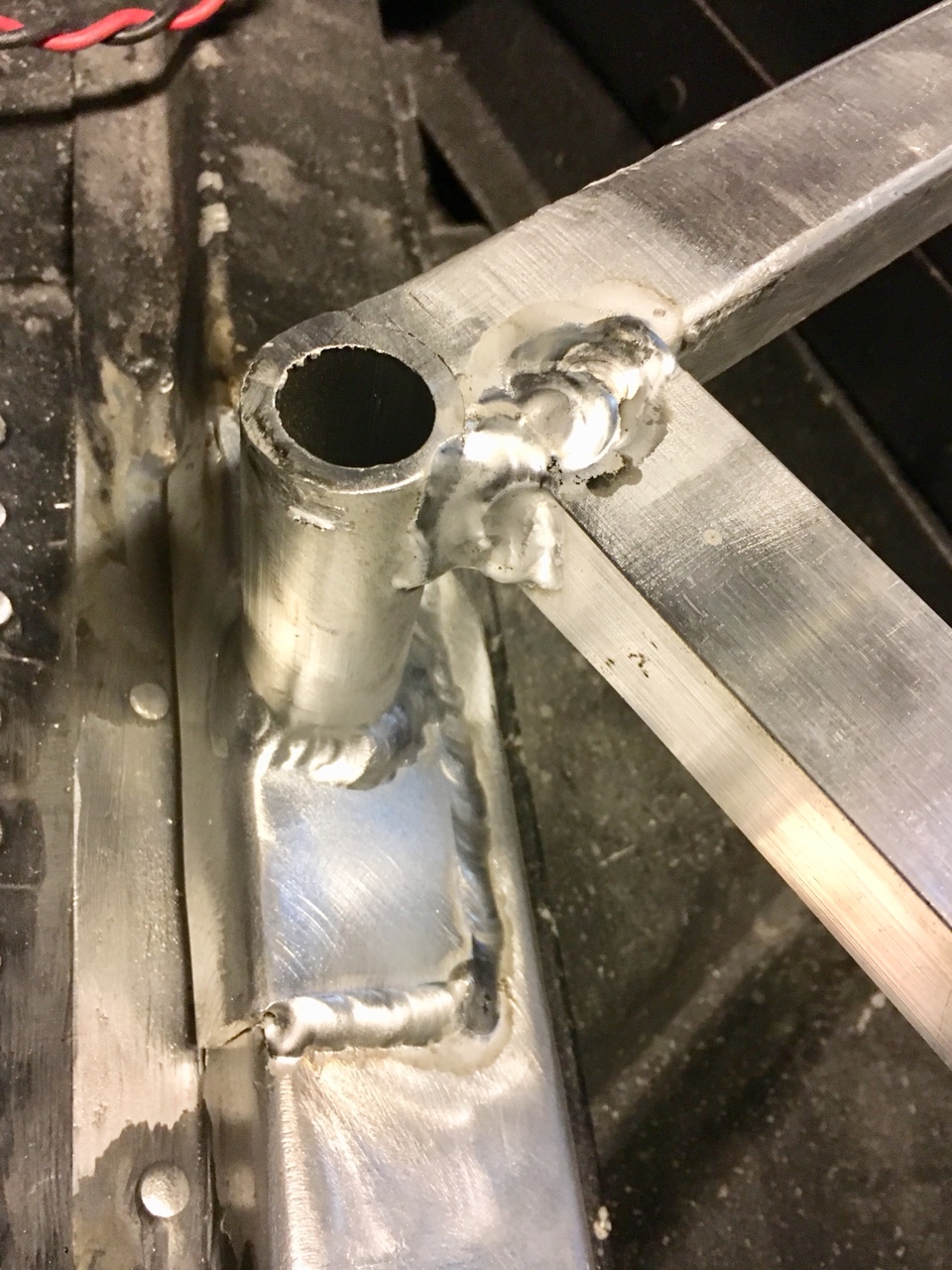

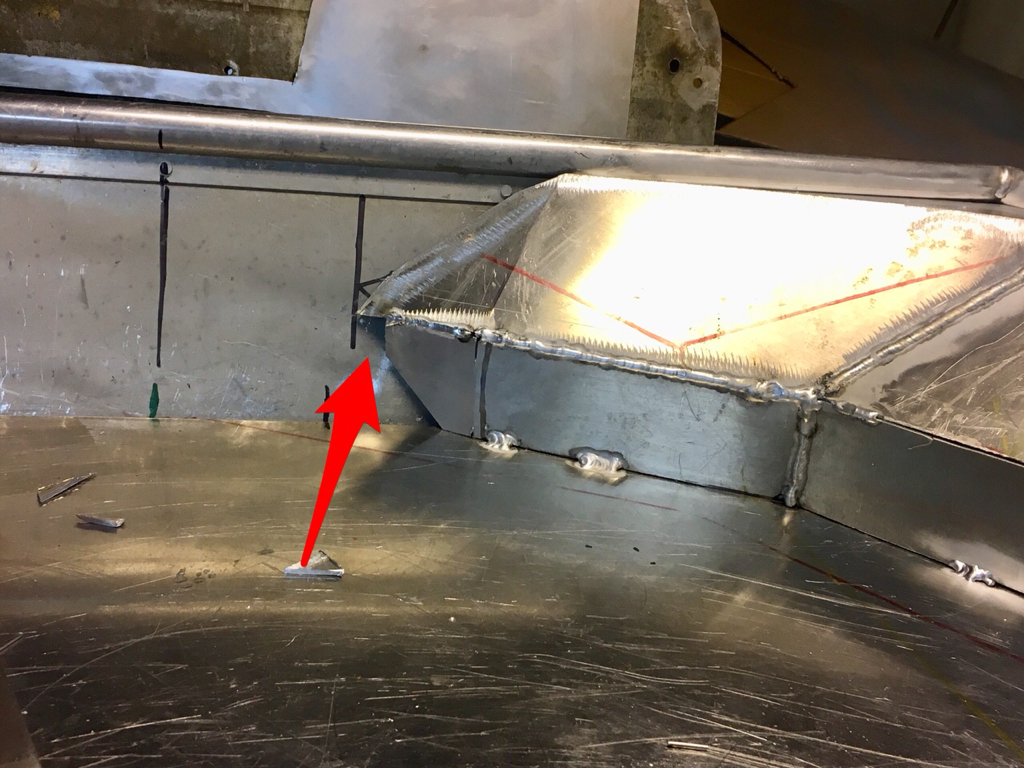

Welded up the bottom first , hotter than I normally weld to get good penetration.

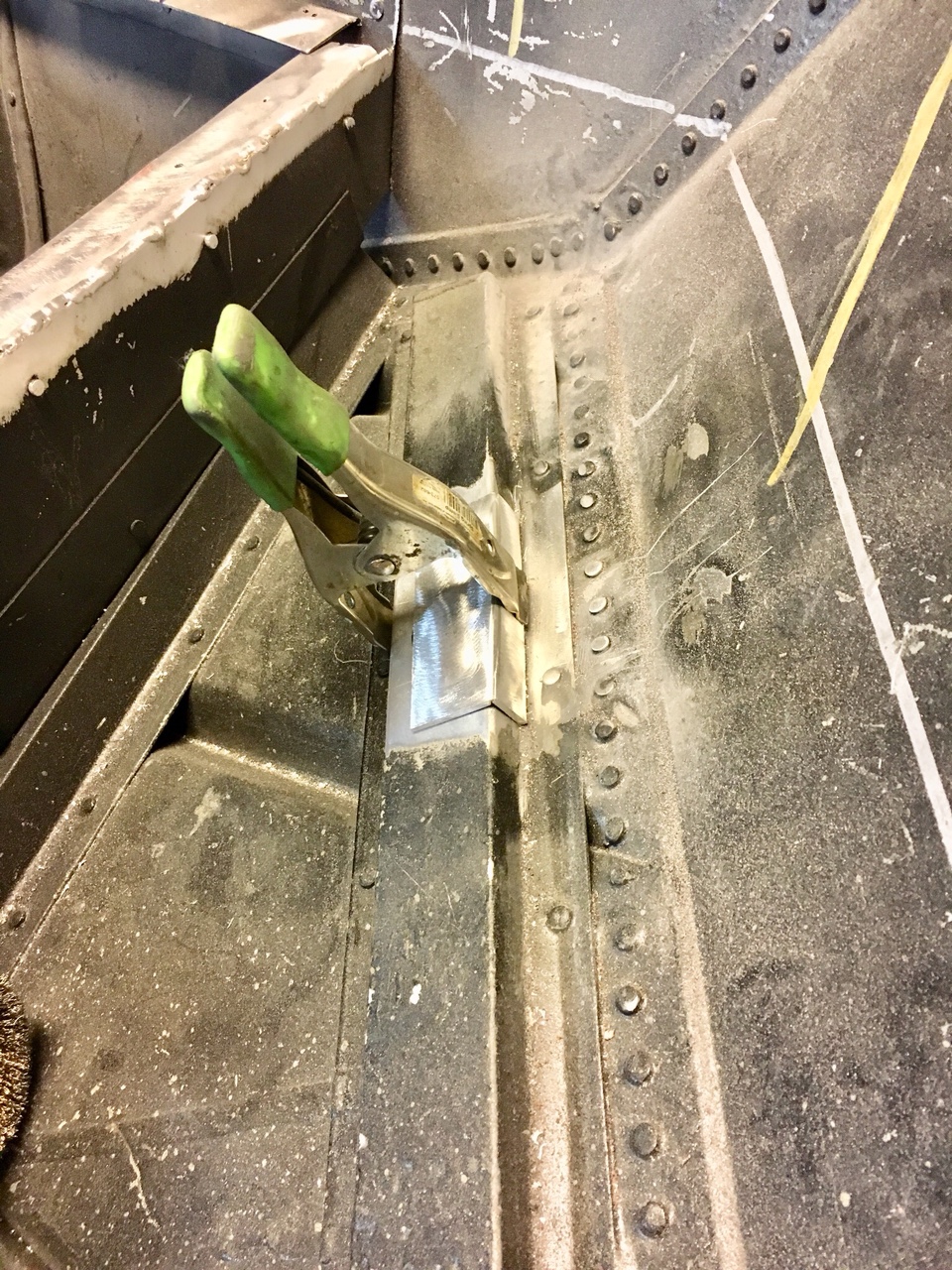

Used backing plates to prevent “blow out” at corners and tried to fight the warpage from heat with scrap sheets and heavy steel weights. Everything was clamped as tight as I could with what I have available.

They may not be pretty but that’s the bottom and I had great penetration on the top side .

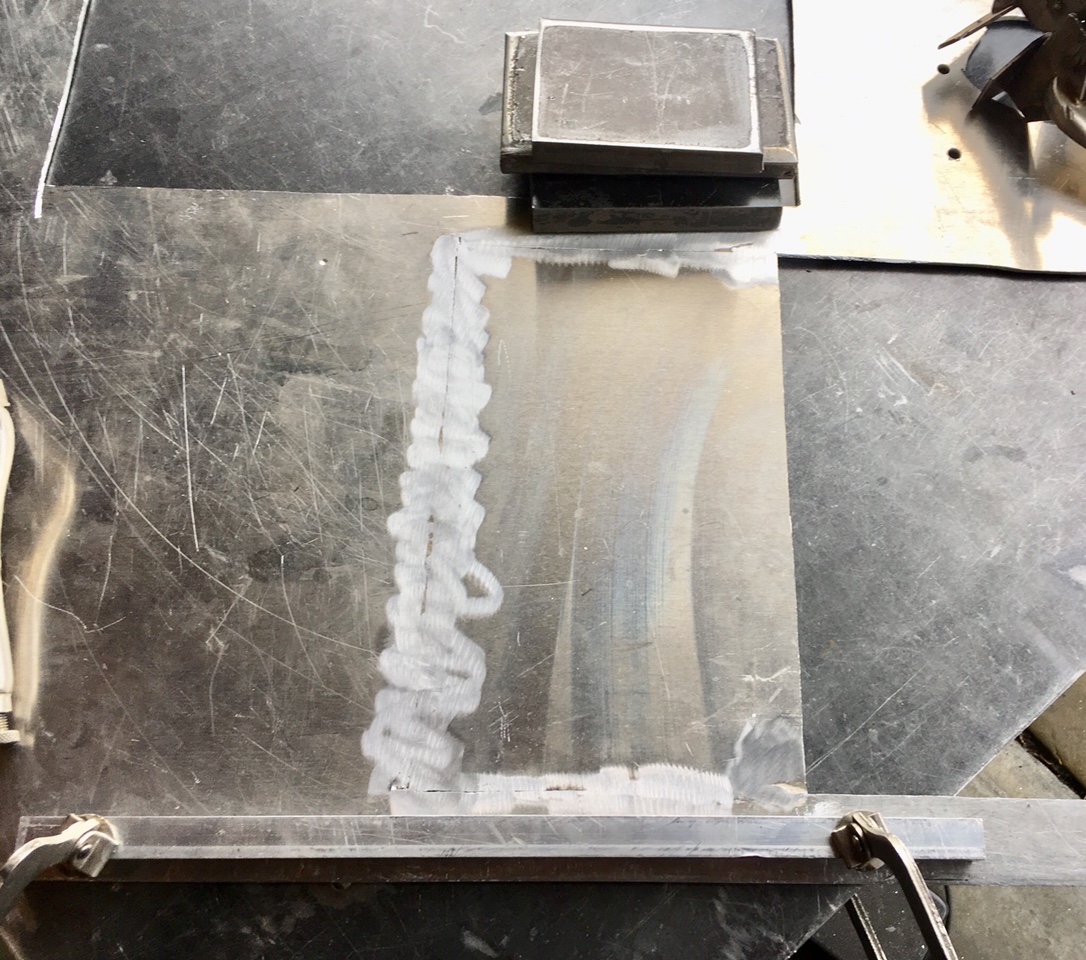

Flipped it over and sanded the area real good to make a sort of

Concave groove section, cleaned with SS brush and acetone wipe. I had to beat out some warpage and turned amps down to 100 and slowly worked my way around a little at a time very gently !

I also thought why not use my air nozzle to blow this thing cool after every small pass. Problem was I didn’t think of that until the second side lol. It worked really well after that and as I am new to welding I’m just glad to learn as I go and enjoy a challenge. [emoji3]

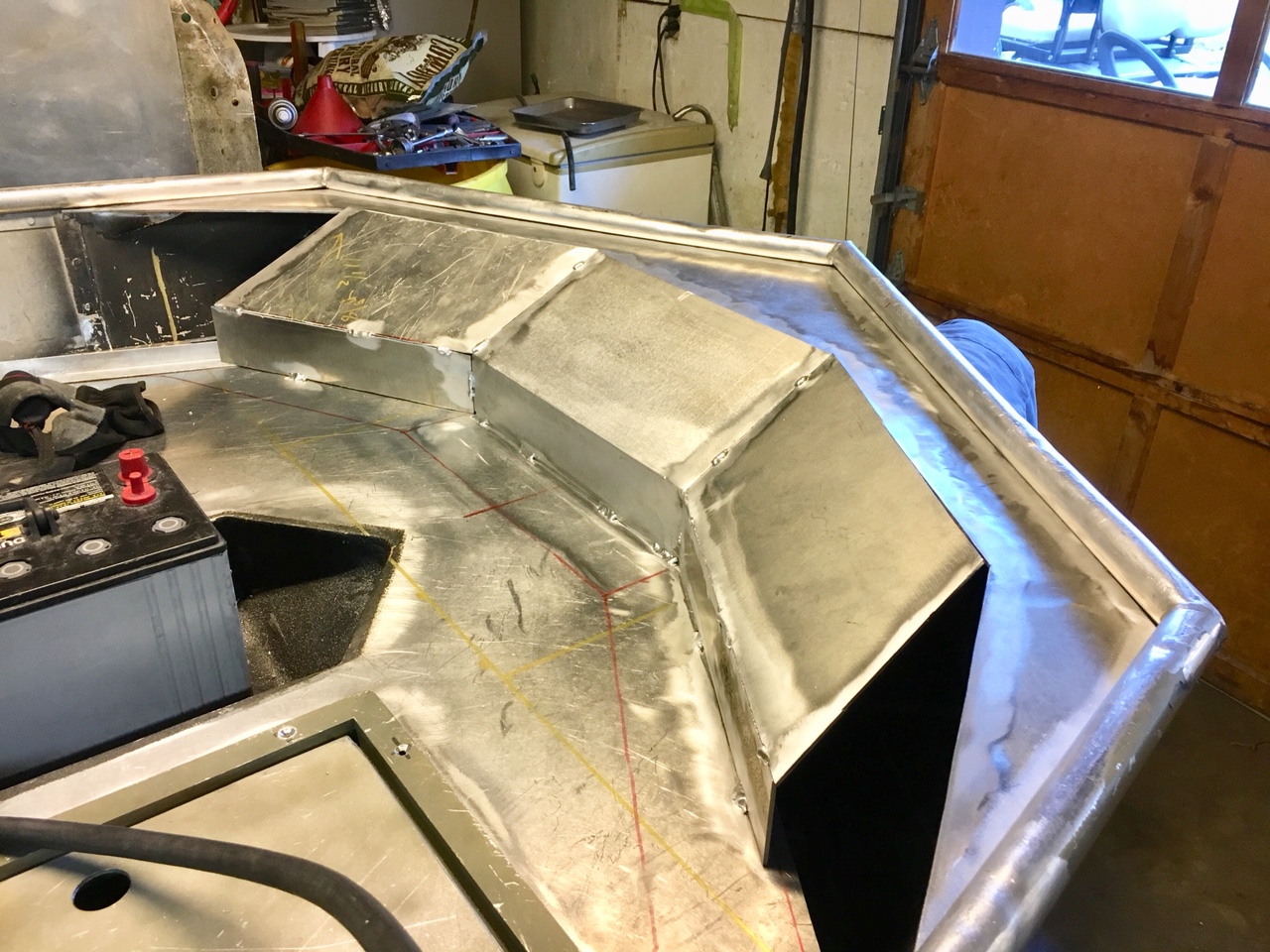

Once I had those 2 filler panels welded in on both sides I sanded down the welds on the top deck real gently [emoji3]

Marked areas with a sharpie that needed attention and then hit it with various grit on a DA sander. It came out pretty nice !

I also slapped some filler on there while it was still warm lol

Now this part was just me being silly I guess because after thinking about it the filler probably won’t hold up to human foot traffic and may chip away at a later date [emoji3] but I’ll hit those areas in the morning with a long board in-line sander and then the DA again but since the final finish will be thick and textured and of a flat color I don’t think that anything would be even visible lol but anyways we will see how it goes tomorrow ! I will be using prowelders tip on heat control for warpage in the future !! Thanks brother !

Now I will be cutting my brand new R&R hatch (the big one) exactly in half , welding ends on them to match what they made (after receiving them and looking them over I know I can duplicate what they have and not “waste” the new door) and installing these 2 “new” doors on each side of the battery compartment for true dedicated storage areas with lots of room and access ! Trust me when I say I am truly happy with R&Rs hatch lids but didn’t wanna waste what I ordered and may just order the anchor locker lid from them now to keep everything more uniform. The one thing I wondered about with their doors is the hinges stick up more than I expected. Is it a game changer ? No not in the least but the ones I built were extremely flush but took every ounce of “smarts” I had to make happen lol. Definitely recommend R&R designs for your hatch needs [emoji3]

I have a little more framing to do to the deck to make it solid and to add the supports for the 2 additional side locker doors. I will then smooth out my greenhorn welds and make sure the deck lays flat and does not rattle

(that would drive me batty on the water lol).

I will also add drains to each hatch door , even the ones I built with U channel to drain them to the bilge area also thanks again Prowelder !!!

I will make another door for the anchor locker up front and still need to add a water draining system to my built in dedicated ice chest/cooler !!

The front bow panel should be this weekend if I don’t run out of argon again !!! I am at the point where I have to decide on it and get started [emoji3]

Thanks for all the great tips, encouragement , ideas and just hanging out !!

After spending 7 months in a traction device I can’t tell y’all how glad I am to be mobile and doing something with my hands again even if it isn’t what I have been doing all my life (wrenchin). Stay tuned this could be epic !!! Ha Ha !