Prowelder said:

I just checked out your whole thread and all i can say is wow. You have some serious time in this thing. Years. I wish you were closer to me i could have helped you save tones of time with the metal work. I will say you got the job done one way or another tho. I've rebuilt 2 boats for myself and 6 for customers over the last couple years. If you get a second check out my tracker build. I definitely catered to my kids. 2 boys 7,4 and a girl 3. I used the best carpet and seats i could find. I also built a saftey rail that can be cut off later on down the road if need be. What are your plans for the interior?

Sent from my SM-G955U using Tapatalk

Yeah unfortunately this has taken way longer than I ever imagined , I pretty much lost all of 2016 and the majority of 2017 !!

I won’t go into all the excuses/reasons but I would be lying if I didn’t say it was probably the hardest couple years we have had to endure.

The good news is I’m “somewhat” back to a normal routine now. I still have major medical limitations but no longer have to punch a time clock and as long as The Good Lord wills it, I have plenty of time to work on this beast. [emoji3]

Now all that craziness aside, I have been following your posts and very much enjoy them and have gotten a ton of ideas reading through them.

Lol, just this morning I talked to Mindy at R&R and ordered 3 hatch lids to see how they will work with my front deck.

Since I have so much time on my hands now I decided about 6 weeks ago I guess to buy a welder and learn how to TIG, I figured since I won’t be able to do much like I used to, I can pretty much sit and spend some time under the hood, which will also help me with this project and I’ll have another life skill to fall back on if it gets tough enough where I have to try and make a living again.

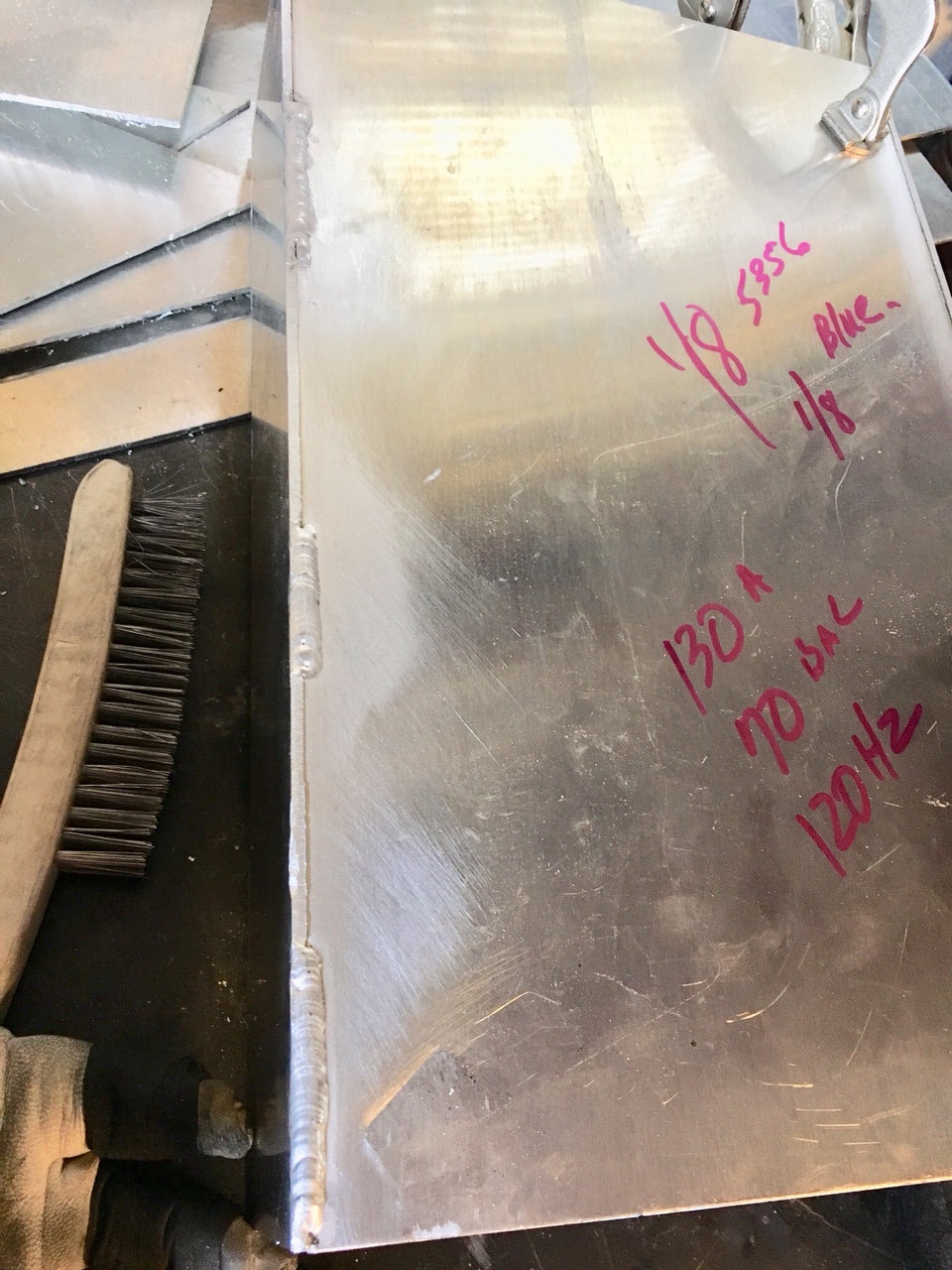

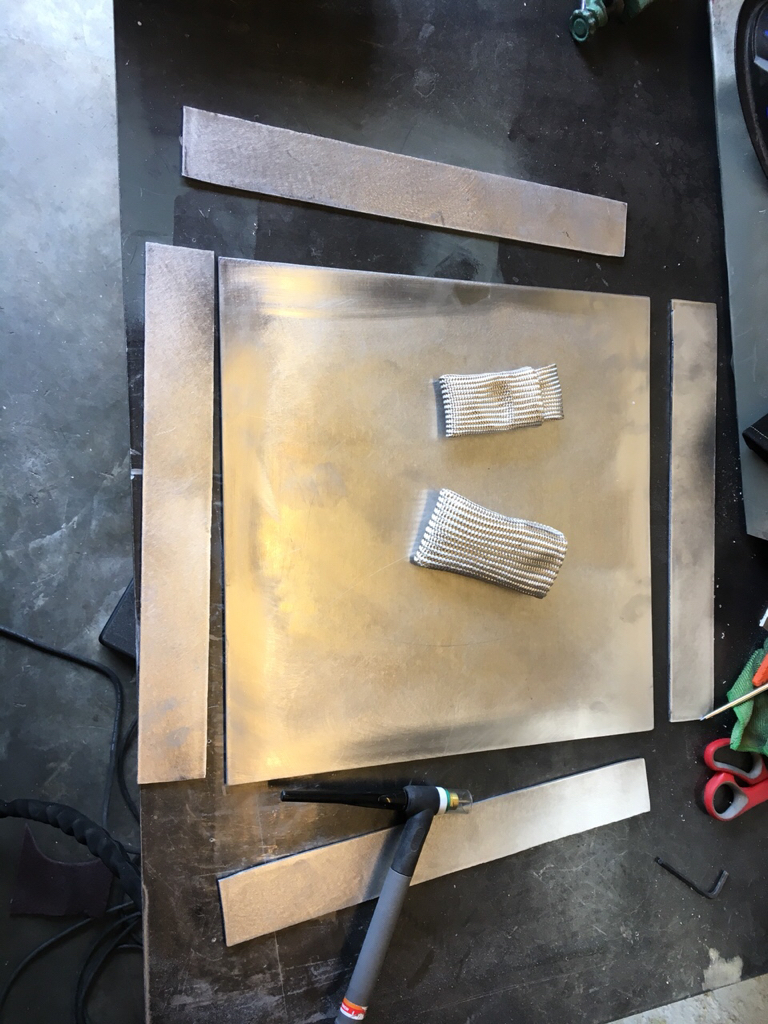

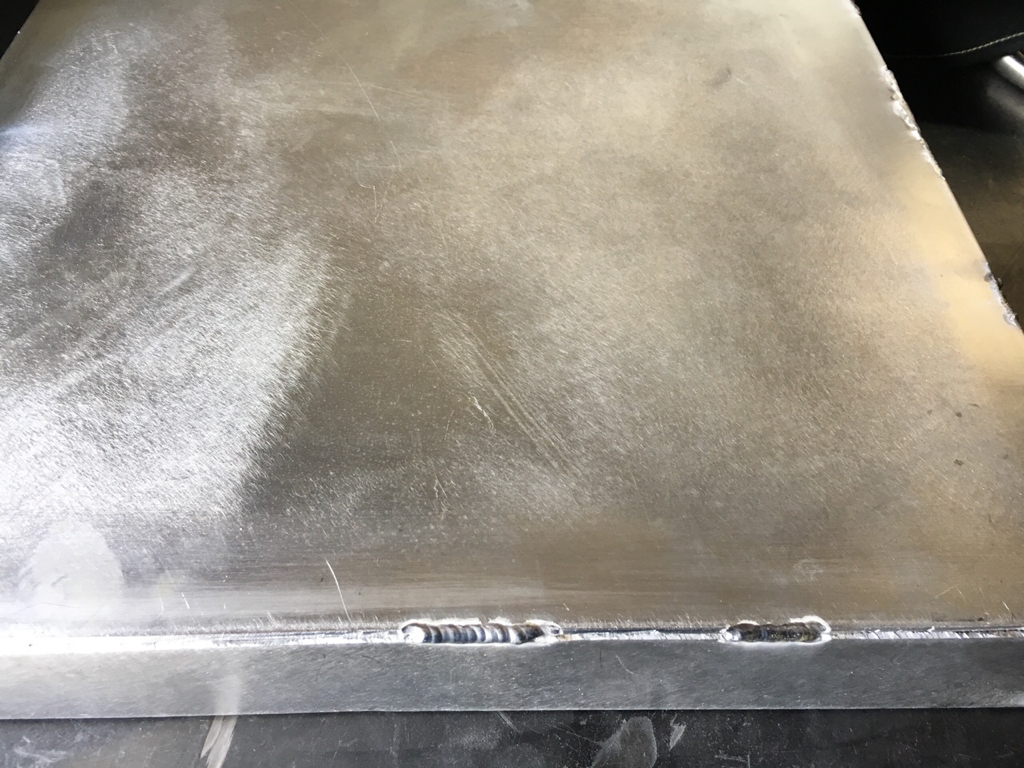

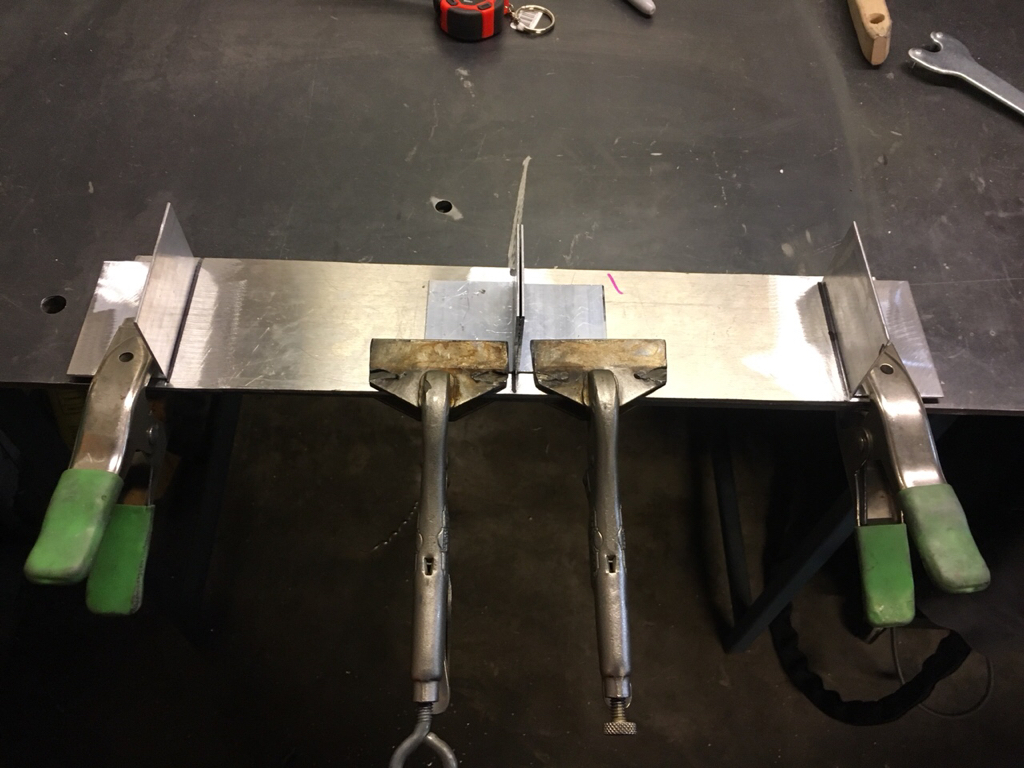

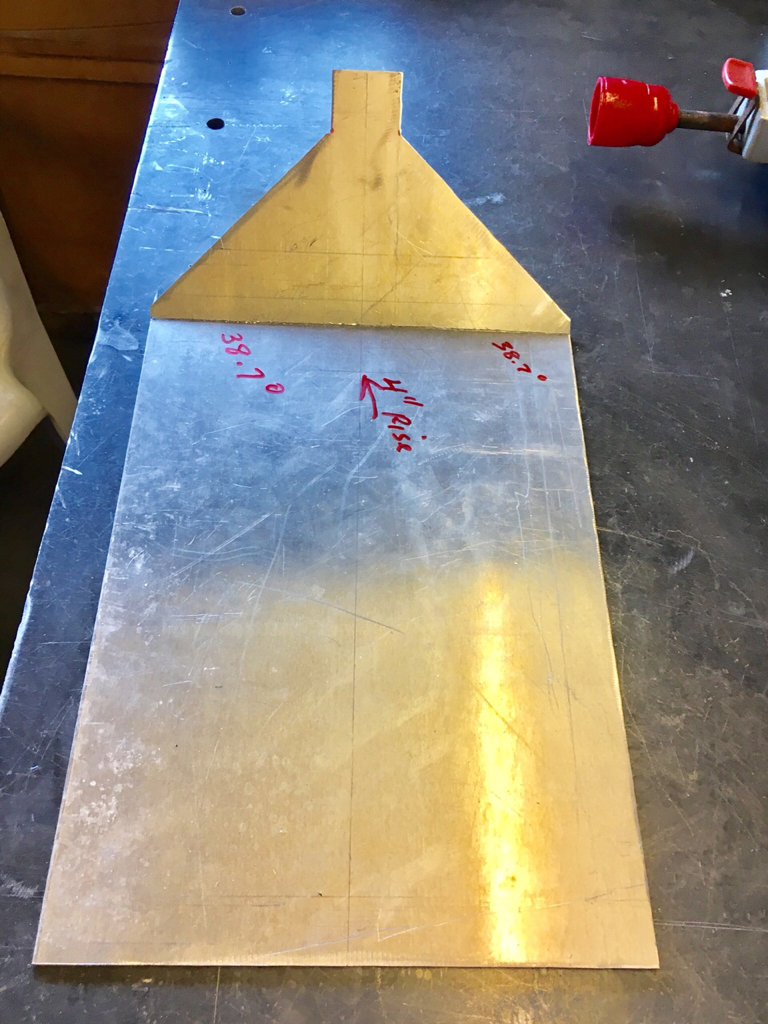

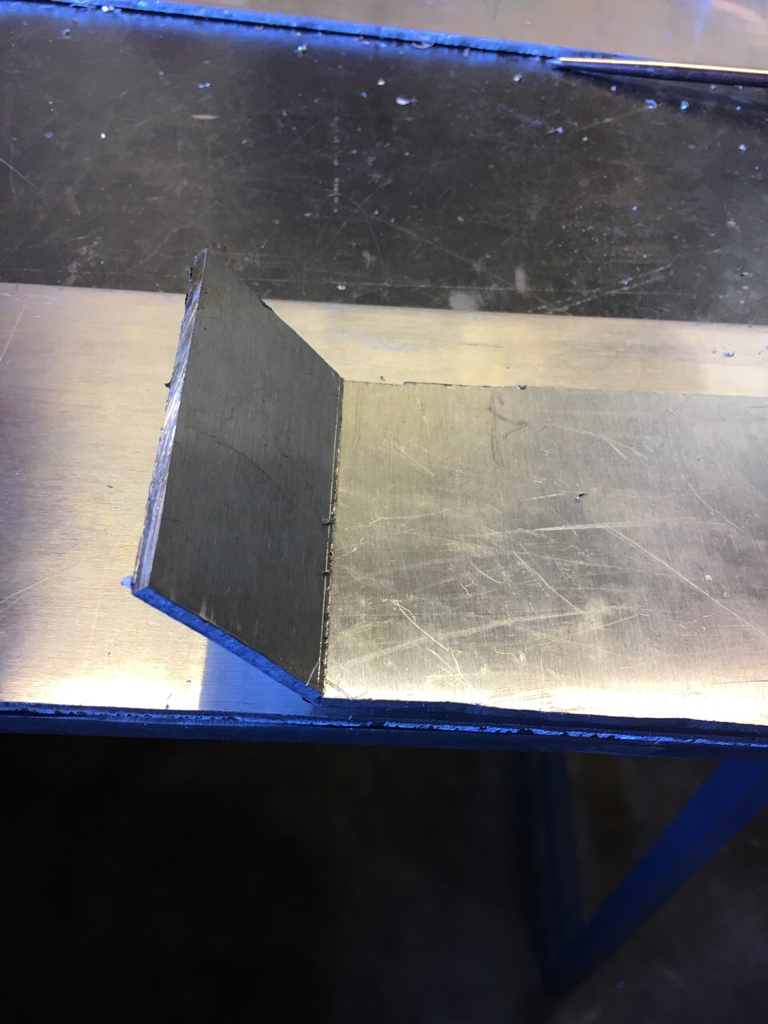

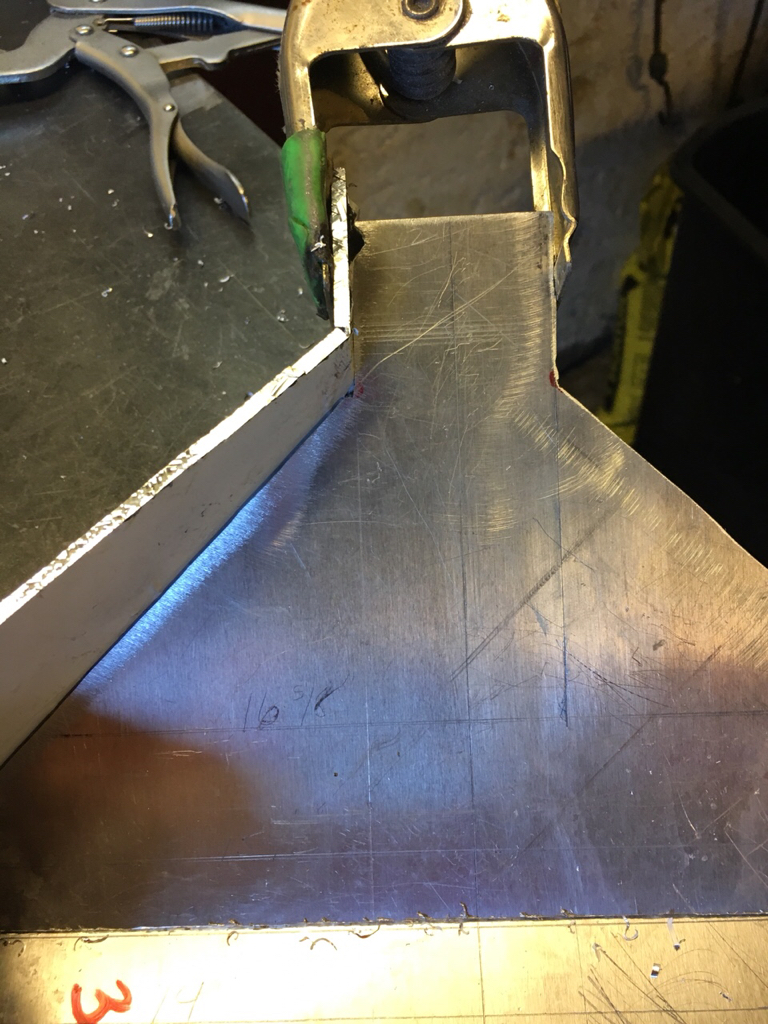

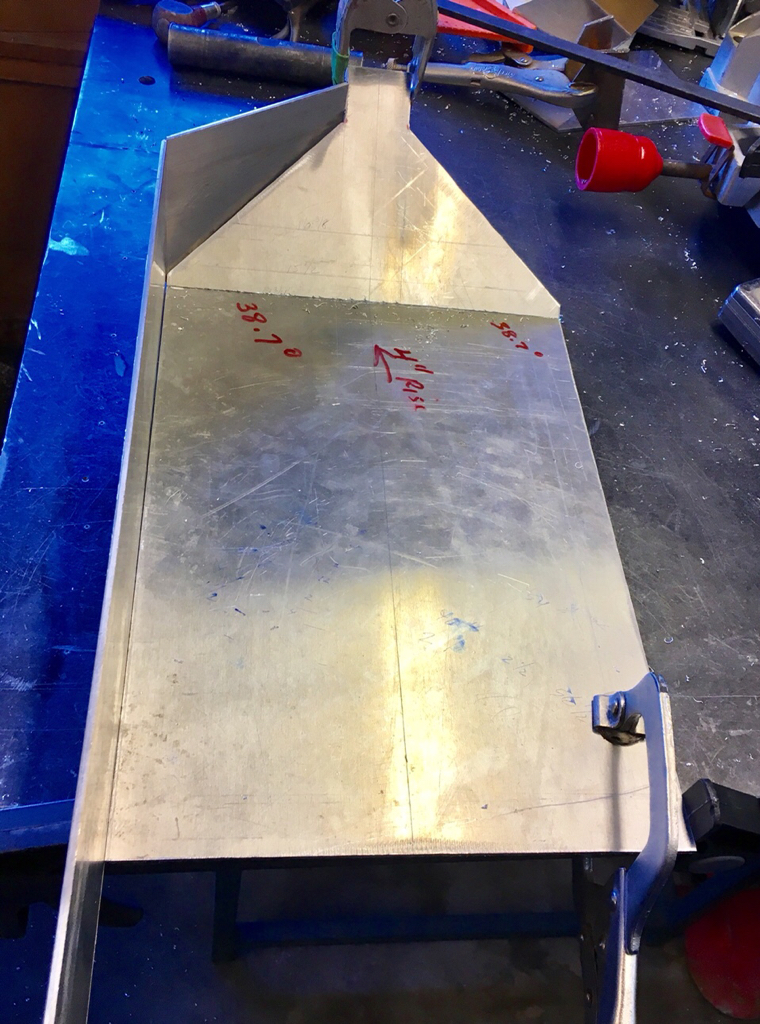

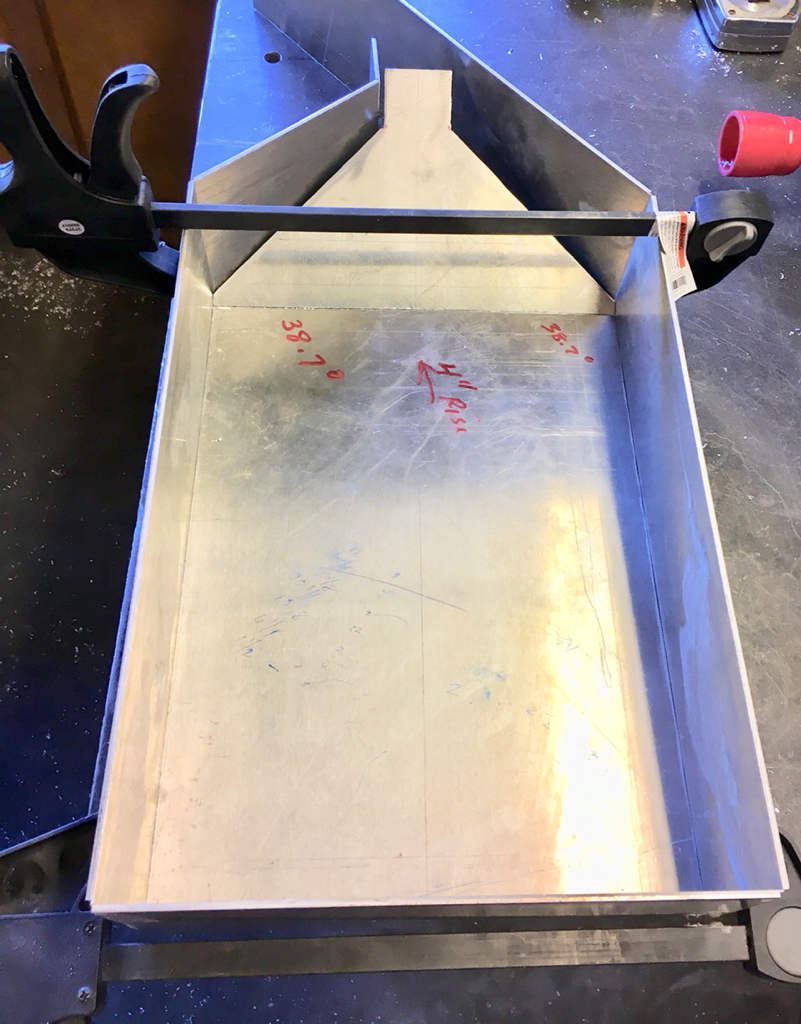

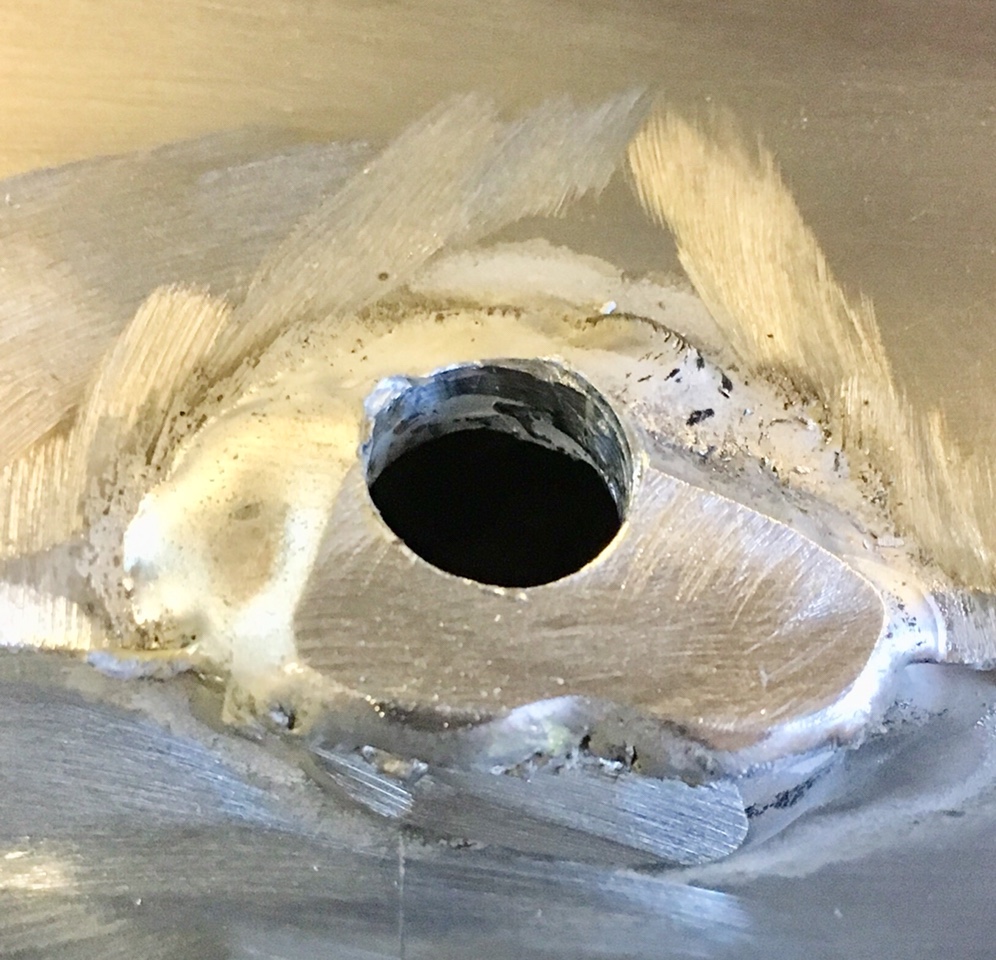

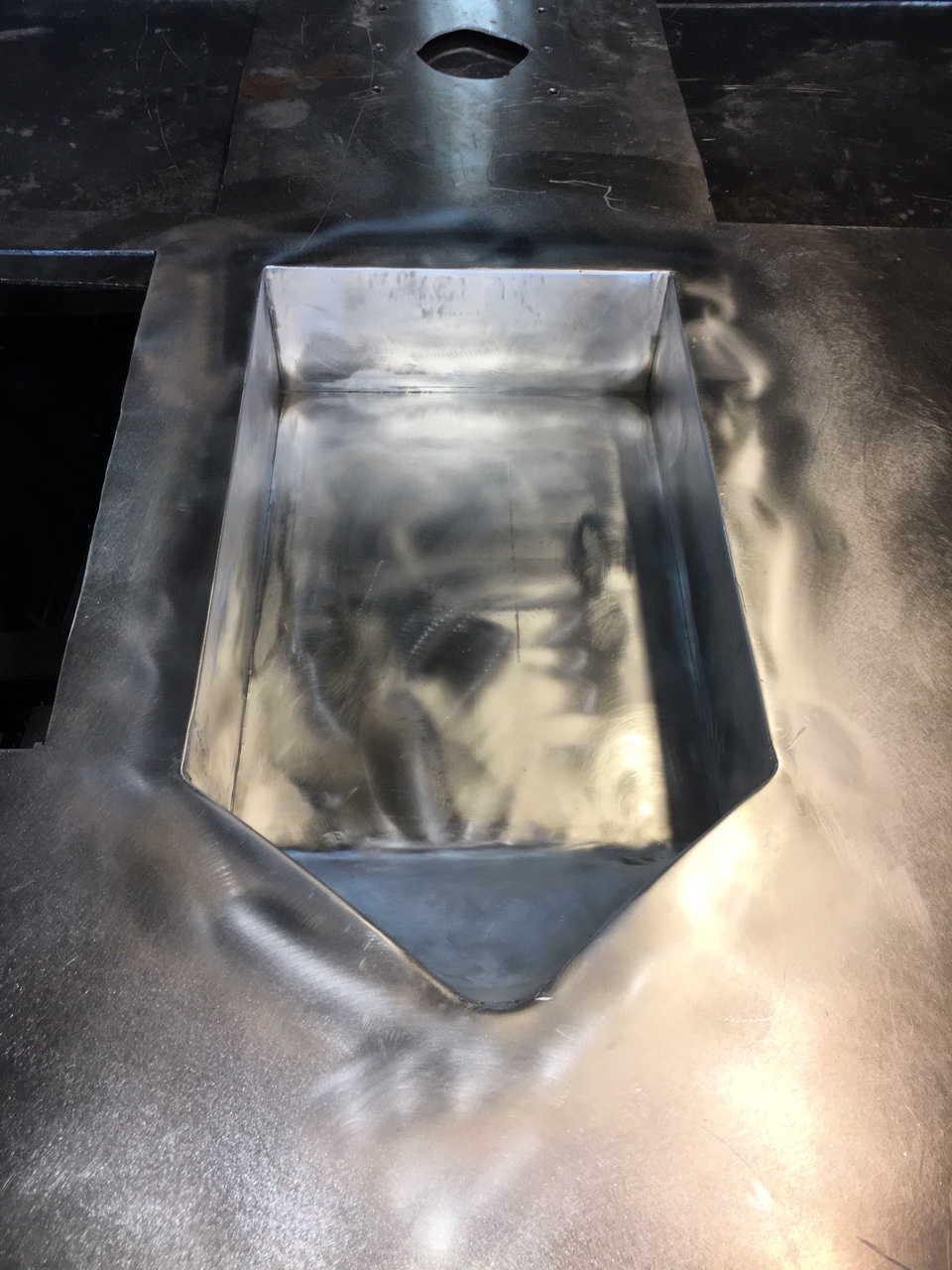

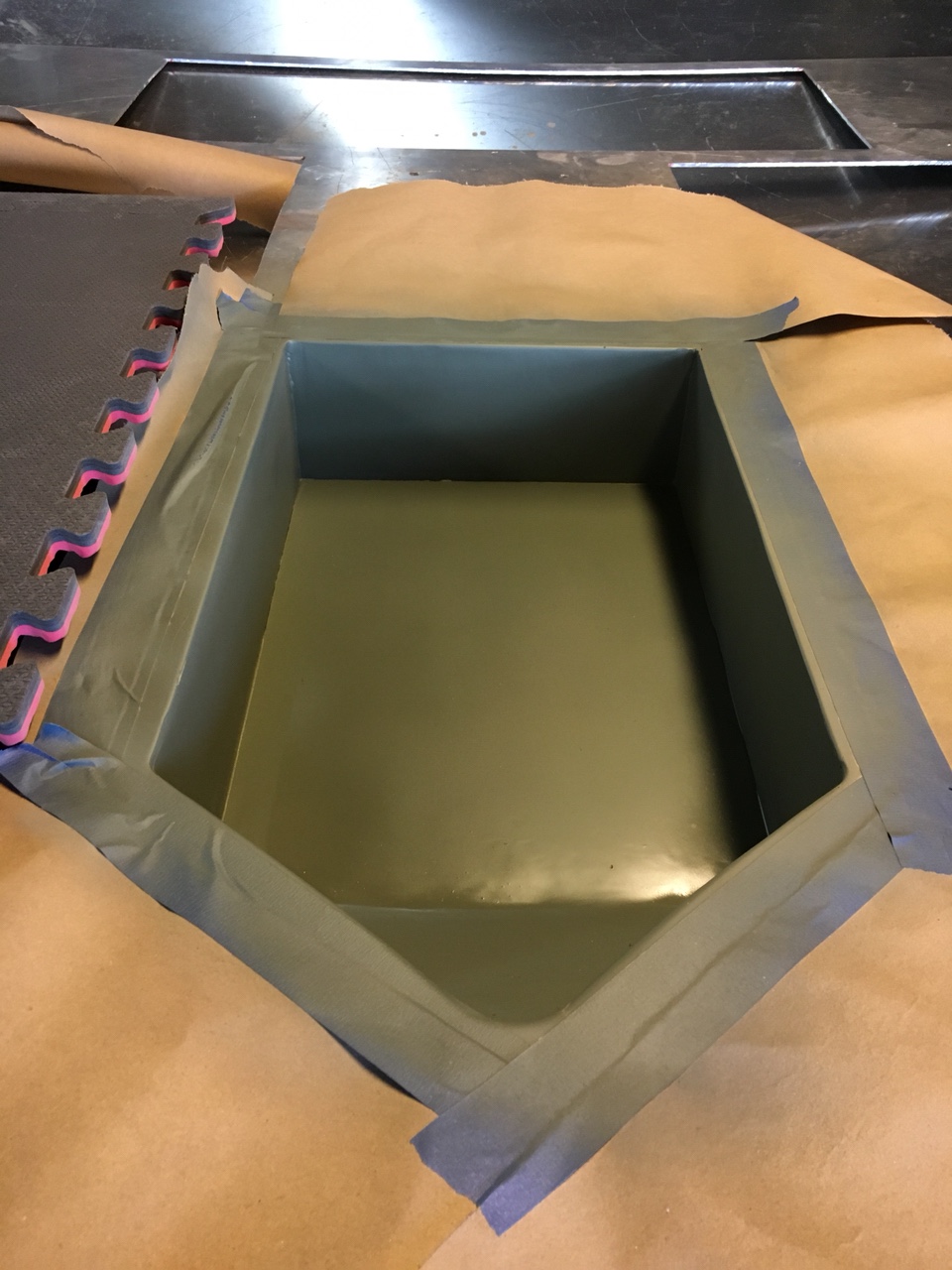

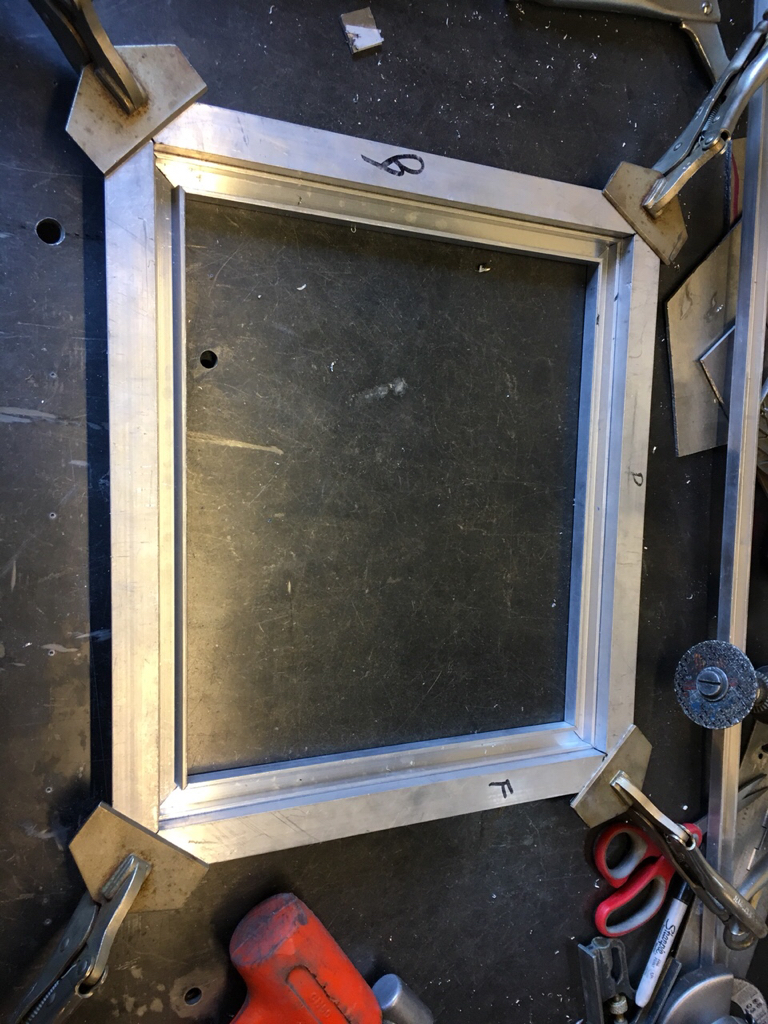

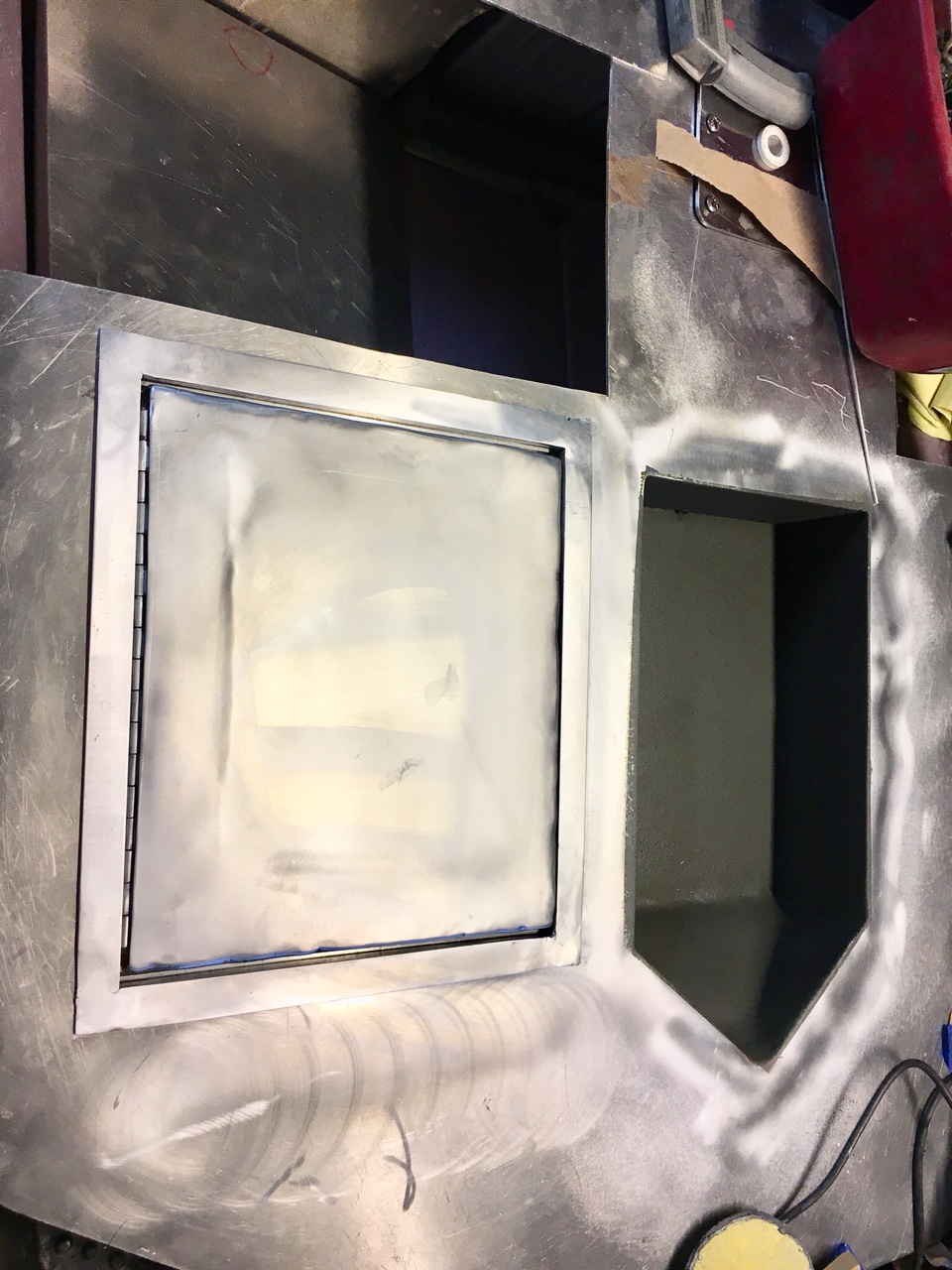

I practiced a couple hours today on my outside corner welds (to make my own dry boxes), this was my first attempt and surprisingly enough they turned out pretty decent! I went to a #8 Stubby gas lens and a 3/32 tungsten and with both 1/8 & 1/16 filler they turned out sweet but I got so excited that I tried to run a couple beads beside it and got it too hot lol. That’s been my biggest problem is heat control ! I’m starting to learn to feed filler pretty steady and been using my foot control more lately to taper off and things like that. I’ve been practicing like crazy and soaking up everything I can, every chance I get. I know it’s just going to take time lol.

And YES I wish you lived closer also LOL.

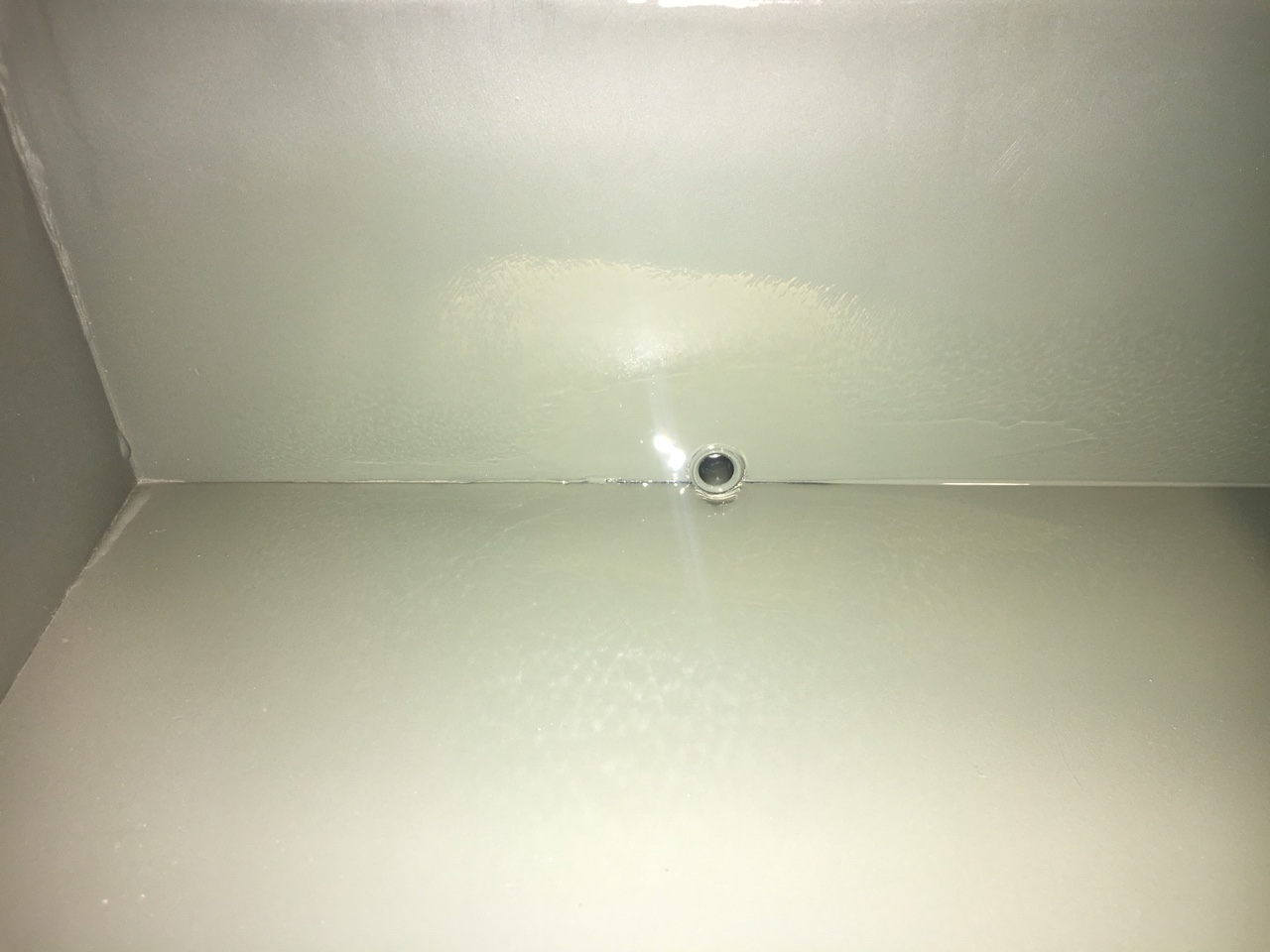

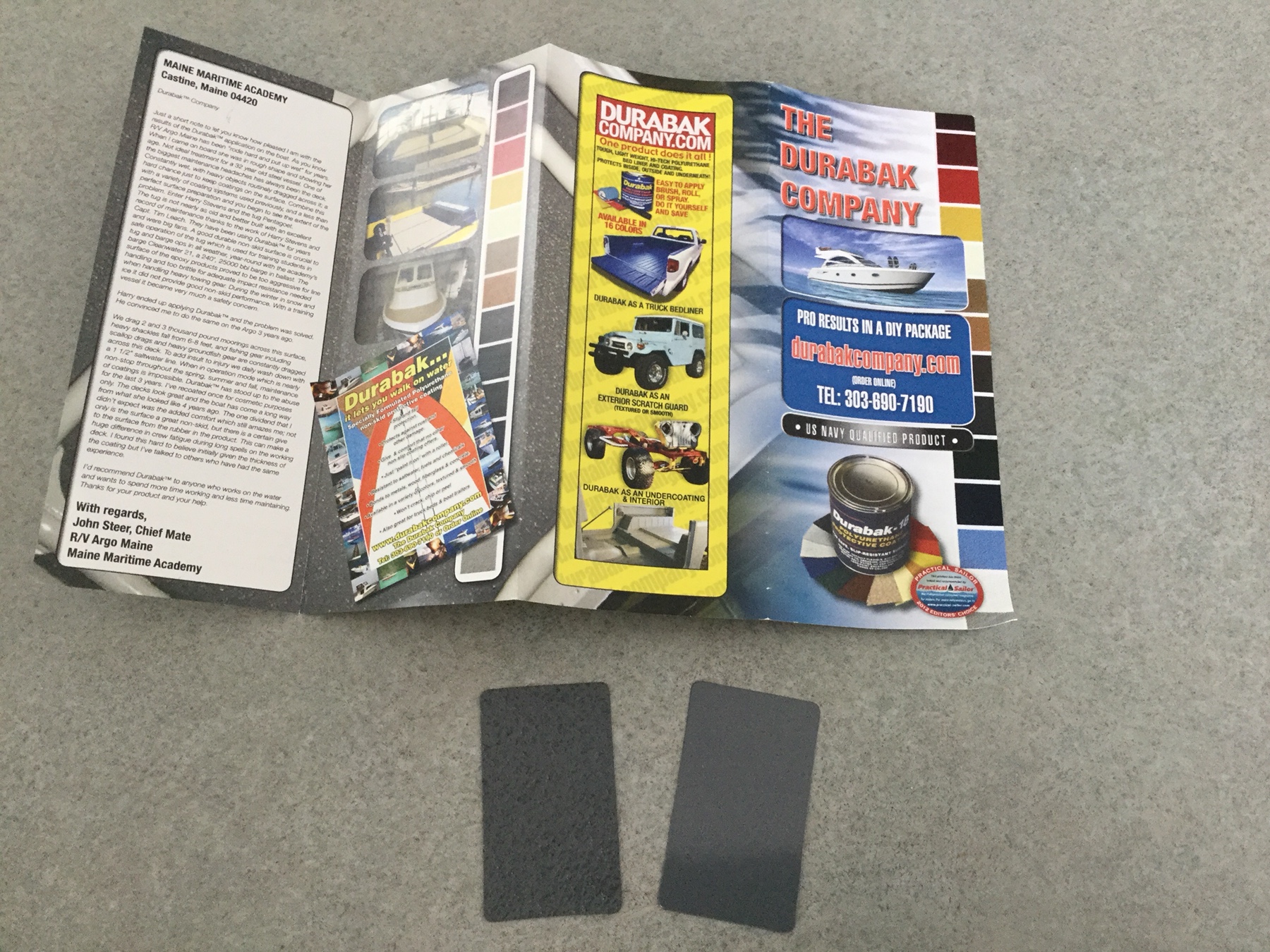

The interior is going to be painted and I was thinking of a non skid surface for the floor but I also have been considering that padding type material, I’m just undecided about that still lol. I’d like to do a Camo paint scheme but that’s still up in the air but may just go with Camo seat covers lol.

I want to put a “jump seat” in the middle of the two tempress frames , one of those was off my Ranger and another I bought from a local garage sale that came off a Stratos. Worked out perfect where I had 2 matching seat frames like this one has

found a jump seat for the center that has a step pad built into the back when folded down similar to this

I am going to get eventually.

I want to box in a insulated cooler in front of the console maybe with couple tool holder slots there for pliers and stuff.

On the port side wall I want to put a set of those newer type rod rack holders that swivel out of the way when not in use like in the newer aluminum, like this one on a Ranger RT188.

The front bow area I wanted to do like the earlier renditions in this post but I think I may have to just stick to this type for simplicity in the welding process

unless my skills get better within the next 3 months.

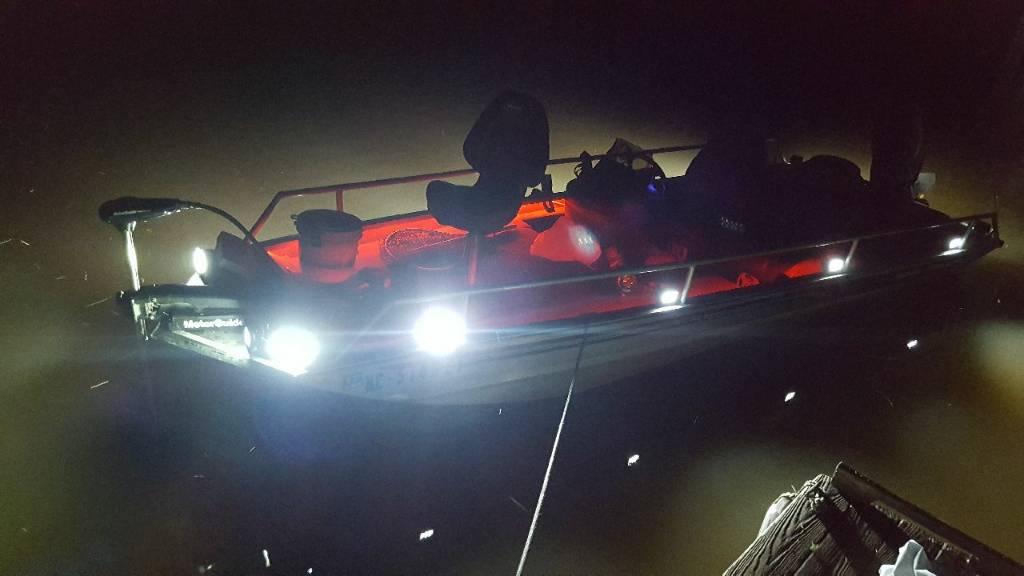

If my doctors release me to fish again I am hoping for a April road test !!!! But will have to play that by ear and I am putting the front bow design off as long as possible lol.

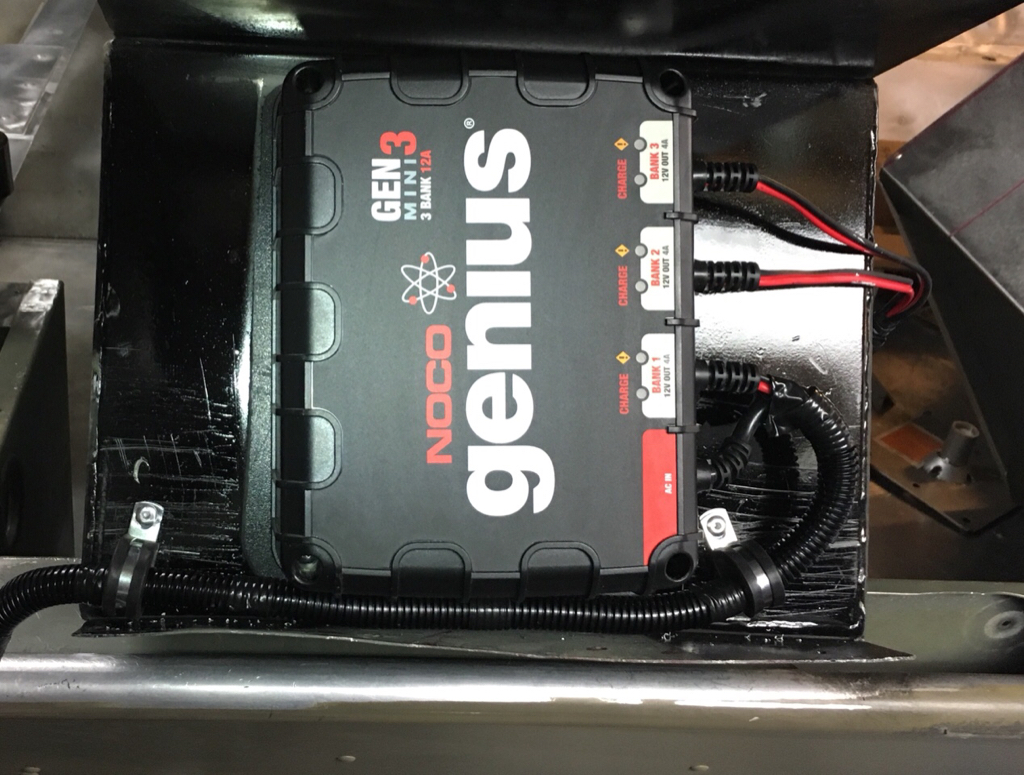

My gas tank and NOCO charger will be here tomorrow, bilge pump on Thursday.

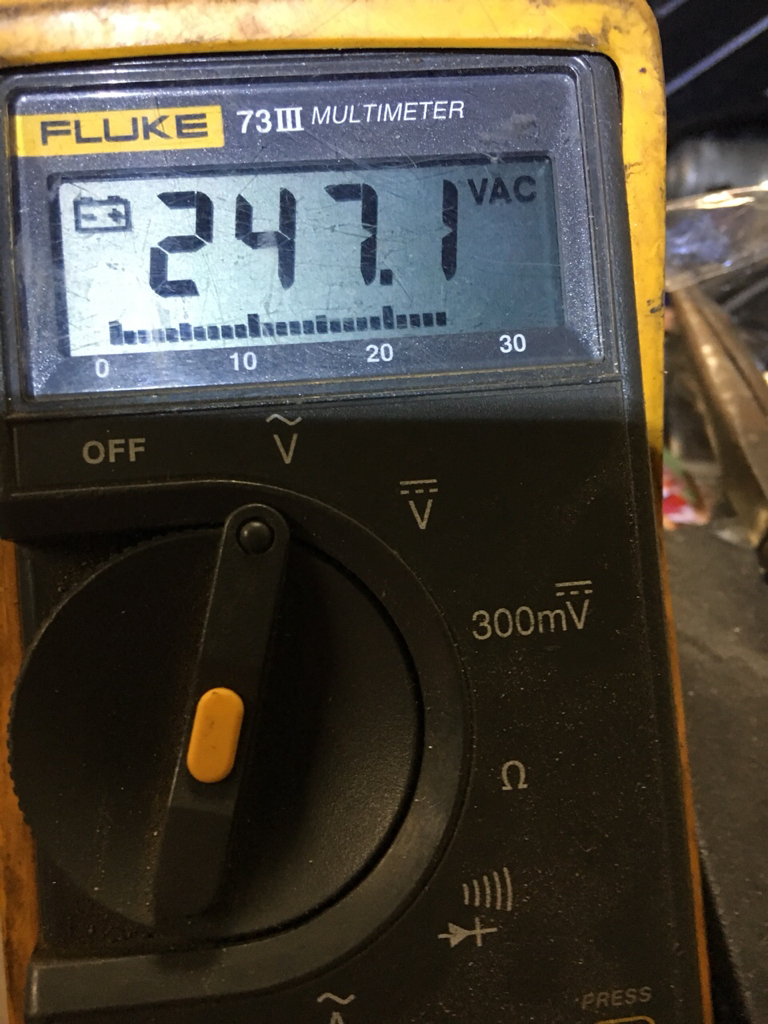

I have the fuse block,battery kill switch, TM breaker, a couple digital voltage gauges , LSS module and a bunch of other small items I need to figure out so hopefully I can start wiring everything up maybe tomorrow. Have a couple early doc appointments and then I got the rest of the day to work on it.

I need to fabricate a transom cap and install a plate to the rear for the motor to mount through. That’s all that’s holding up the motor being mounted back on it.

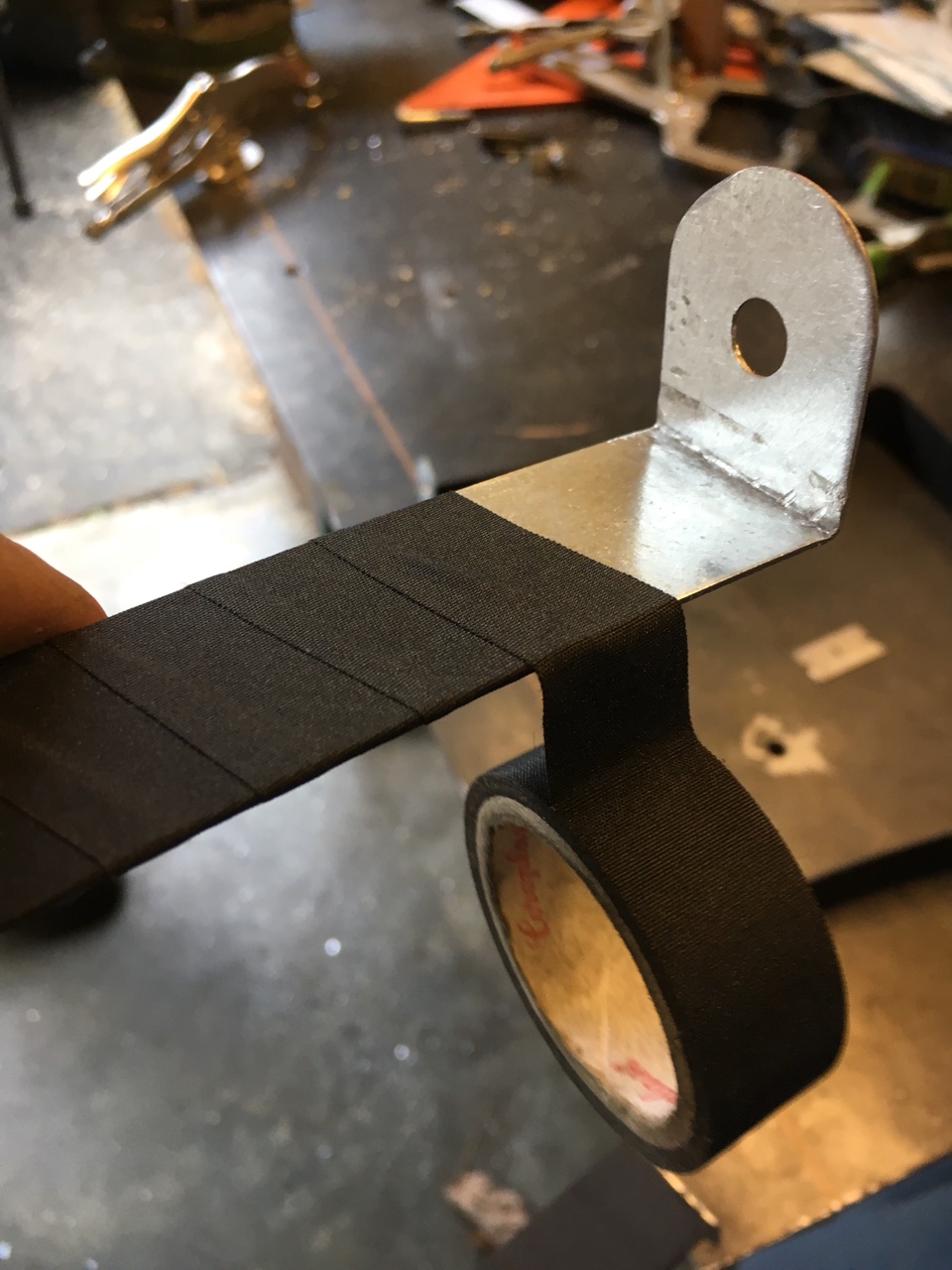

I’m going to attempt to bend a 90 on a 56” Long piece of 1/8 5052 and then hopefully I can weld the remaining piece to make a U channel and fit it to the transom since it’s 2 bends so close together ( 1 1/2” apart).

Tomorrow I am going to play around with bending some curves so I can build my own trolling motor tray but I want the curved front design much like some of the factory bass boats used to have.

I also need to find me some 1/4 to make a TM mount out of but have thought I could just weld 2 1/8 sections together if that would work. I have a lot of aluminum left but also been practicing a lot and it’ll probably go faster than I realized. I went below a 1000 on my argon bottle today lol. It’s going fast !!

Anyways I’m rambling brother ! Thanks so much for dropping by and can’t wait to see how your latest build turns out.