wmk0002

Well-known member

I picked up a 1990 Yamaha 25, model 25ESD, Friday. Had good even compression and started and briefly ran so I got it. Got home and checked the spark and looked it over good and found nothing that stood out....until I looked up the plugs that came out of it. Thought they looked incredibly small when I was buying it and turns out someone had put small weedeater or chainsaw plugs in it lol. Put the correct ones in it and it actually sounds halfway decent when it runs now. Like I said, I can't find any issues or concerns that stand out as of yet but it really makes you wonder what all else someone who would swap plugs like that my try to have "fixed".

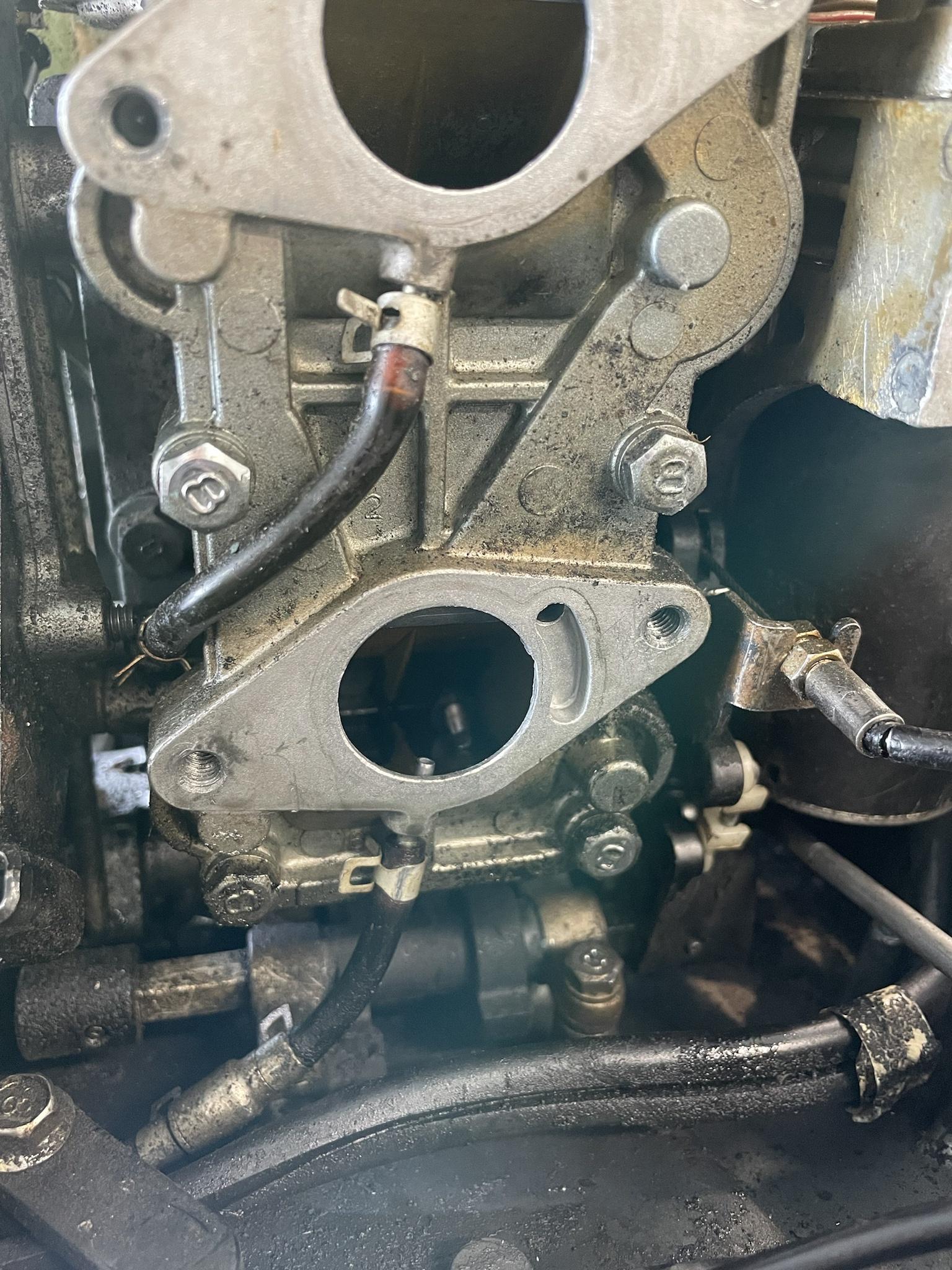

I ordered a used $20 factory service manual from Ebay and went ahead and ordered a new fuel filter, generic kill switch, and lower unit plug washers. Surprisingly, the water pump was done correctly by someone as it pumps like a champ. Plan to pressure test the lower unit and reseal if necessary, then clean the carbs, replace fuel lines/filter, and do a full link and sync and I guess let her rip.

My only concern is the oiler system. I know the service manual will give me the procedure and flow rate to test it for but as someone who has never had a direct oil injection motor (or one not already disabled) it gives me pause as at least someone in the past has touched this thing who shouldn't have been wrenching on anything. I have 3 gallons mixed at 50:1so I am covered though. Is this a motor where I should fully delete the oil system or should I test it and if it passes just roll with it?

I ordered a used $20 factory service manual from Ebay and went ahead and ordered a new fuel filter, generic kill switch, and lower unit plug washers. Surprisingly, the water pump was done correctly by someone as it pumps like a champ. Plan to pressure test the lower unit and reseal if necessary, then clean the carbs, replace fuel lines/filter, and do a full link and sync and I guess let her rip.

My only concern is the oiler system. I know the service manual will give me the procedure and flow rate to test it for but as someone who has never had a direct oil injection motor (or one not already disabled) it gives me pause as at least someone in the past has touched this thing who shouldn't have been wrenching on anything. I have 3 gallons mixed at 50:1so I am covered though. Is this a motor where I should fully delete the oil system or should I test it and if it passes just roll with it?