DaveInGA

Well-known member

Trailer hubs now ready to be installed:

Hubs ready to go. Any leftover grease from packing was wiped off in the hub to help fill it with grease.

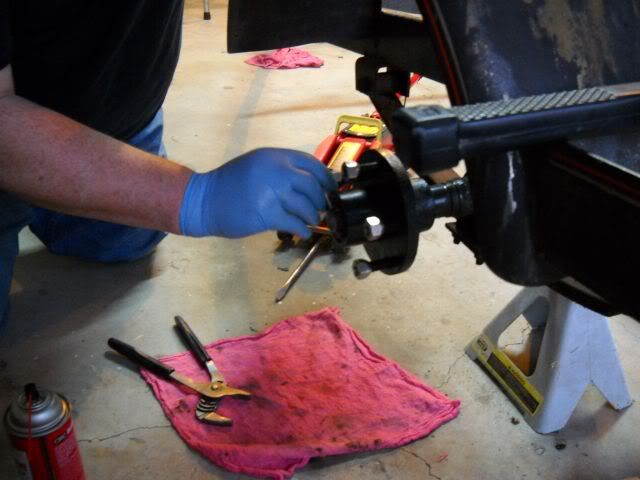

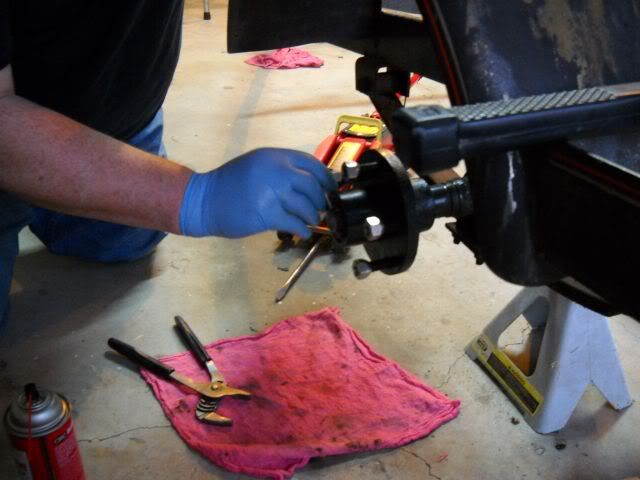

Installing castle nut. First, turn down as far as possible by hand.

Tighten down with slip joint pliers. Keep tightening until you "feel" the bearing press against the face of the shoulder in this case. At this point, the hub should be difficult to turn and is "too tight."

The back of the hub and you can see the hub is now overlapping the thicker portion of the axle like it should be. This allows you to place your cotter pin and have proper tension on the castle nut along with proper movement of the hub.

Backing the castle nut off enough to place cotter pin.

Don't forget the cotter pin and don't forget to bend it down to lock it into place! About ready to install bearing buddies.

Hubs ready to go. Any leftover grease from packing was wiped off in the hub to help fill it with grease.

Installing castle nut. First, turn down as far as possible by hand.

Tighten down with slip joint pliers. Keep tightening until you "feel" the bearing press against the face of the shoulder in this case. At this point, the hub should be difficult to turn and is "too tight."

The back of the hub and you can see the hub is now overlapping the thicker portion of the axle like it should be. This allows you to place your cotter pin and have proper tension on the castle nut along with proper movement of the hub.

Backing the castle nut off enough to place cotter pin.

Don't forget the cotter pin and don't forget to bend it down to lock it into place! About ready to install bearing buddies.