All right! I made some good progress on my transom rebuild over the weekend!

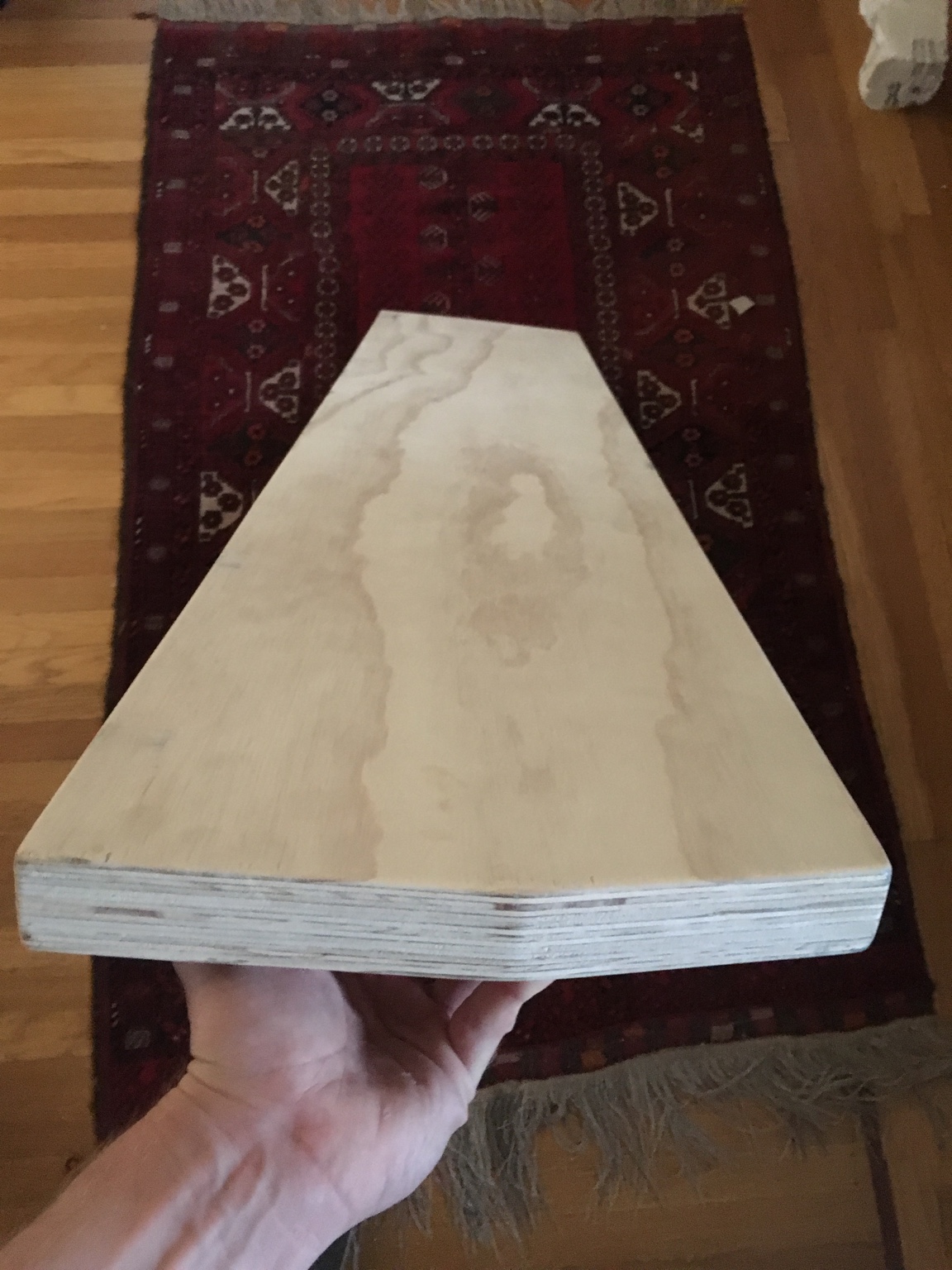

I cut the two triangle-shaped transom braces, and fabricated some aluminum plates to secure them back together. I also removed the old transom wood (wow was it sh*tty...) and laminated up a new one using ACX plywood and Titebond III glue (pics to come).

Before I reinstall the wood, I want to do a nice job patching all the extra holes (red circles in the attached photo) that have been drilled through the aluminum transom. Some holes are below the water line, and some are above. Some will be hidden under the transom wood, and others will be visible from inside the boat.

Here's how I plan to repair the holes. Please let me know what you think.

1) Remove all the old patching materials (JB Weld, I think? 5200 maybe?).

2) Lightly sand/scuff the aluminum surrounding each hole, then wipe clean with acetone.

3) Using JB Weld, glue small (approx 1" square or round) patches of ~1/32" aluminum sheet on the INSIDE of each hole to act as backing plates. Allow to set.

4) Apply JB Weld to each hole on the the outside, filling the void in the aluminum. Allow to set.

5) Sand each repair on the outside, leaving just a small circular spot of JB weld at each hole.

How does this sound? I'm leaning toward this ethos because I think it will give me a solid repair that doesn't stick out like a bolt/nut/glue patch would. Many of these repairs will be under the transom wood, so they can't stick out at all.

Thoughts?

Sent from my iPhone using Tapatalk