JRyno10

Well-known member

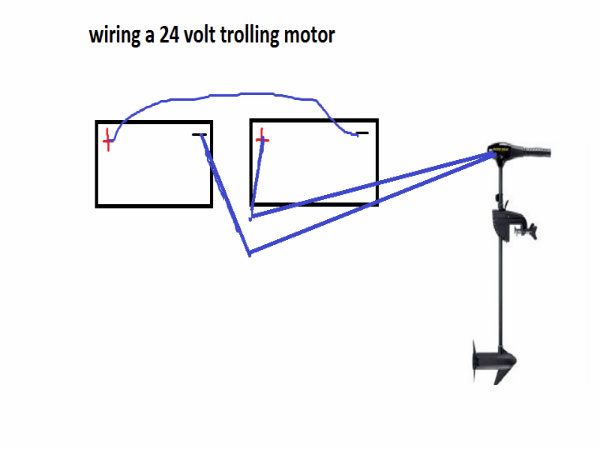

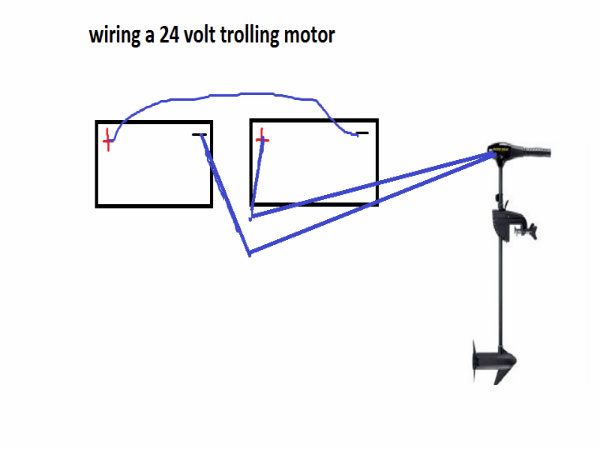

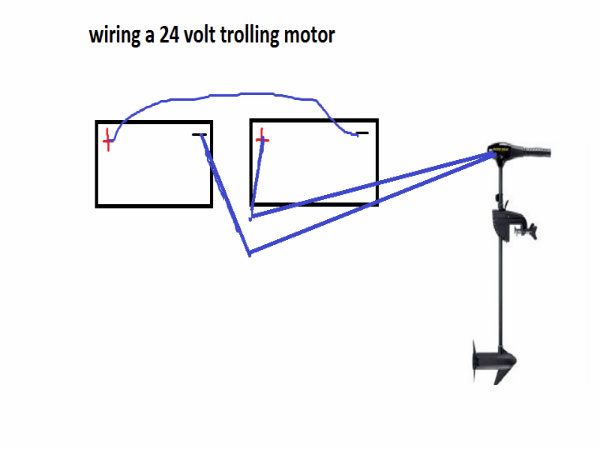

Is this the right way to wire a 24 volt trolling motor? Not a very good drawing but I think it looks correct.

Buddychrist said:I would not solder or use crimp connections.

Heat shrink electrical connections are the best when it comes to boating because they are waterproof, solid connections, and easy to remove later if you needed to do any work on the trolling motor

Bob Landry said:I do a lot of electrical work in the course of my marine business and use only crimp connectors. applied with a quality crimper and covered with adhesive lined heat shrink. I have never has a connection fail or corrode, but if I were to have to redo a connection for any reason, the most wire I would lose is 1/2".

I don't recommend solder because it really isn't needed and most people do not know how to solder and not melt the insulation or wick solder up under it, especially on the heavier wire.

JRyno10 said:Thanks everyone for the input. I probably should do something better about my connections. They are just crimped and then I put electrical tape over it. However I checked all my connections, and recharged the batteries - then tested the TM in my garage. I ran it at various speeds for about 20 minutes and it ran perfectly fine and it only took my batteries from about 11.90 to 11.84. Although I'm sure this may change when the prop is actually in water and has resistance. I think I am about to go out and give it another shot

jmcaswell said:If I have my trolling battery in the center bench, and my trolling motor on the front bow, that means I would have to run roughly 10' feet of wire from battery to motor- is this ok to have the length that long? Def adding a amp breaker up front.

Jim

jmcaswell said:Thanks Russ- I think I owe you some kind of consulting Fee at this point- great info!

So I will use thick G wire- but "distance" from battery to motor is ok? 10FT?

Enter your email address to join: