PSG-1

Well-known member

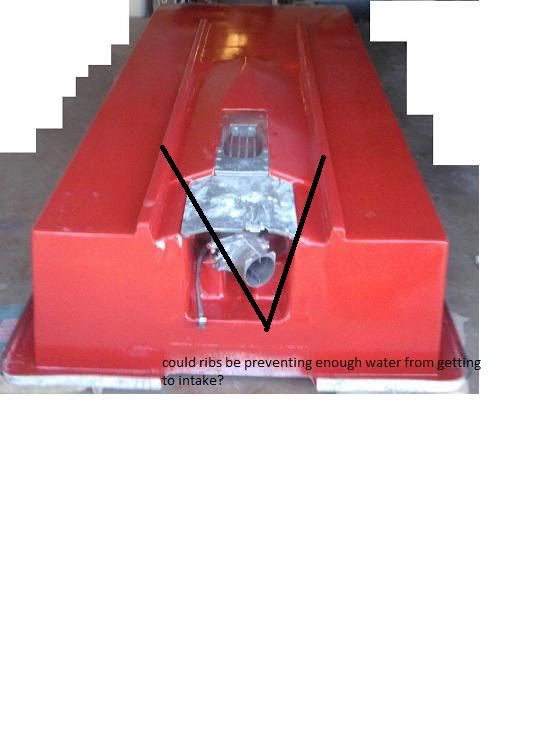

majkowskid said:do you not think it could be from the ribs on the bottom of the boat that are in this pic?

or is my spoon area not right?

No, but looking at the pictures, it appears that you have a 'step' between the hull and the body of the pump intake, it appears the pump intake is not flush with the hull, like it may be inset by a half inch or so. (Correct me if I'm wrong, and if I'm wrong, then, ignore the next part)

This step could be part of your problem, it will cause turbulence, right before the intake, which is something you do not want to do.

You could try to fill this void somehow, and try to blend and taper it, but the pump is still going to be inset from the hull, so, I don't think that will eliminate the problem.

Hate to say it, but it looks like the best option is to try to drop the pump a little bit, to get it flush with the bottom of the hull. Unfortunately, this may also mean having to change your motor mount design, to also drop the engine lower, to keep in line with the pump when you lower it. I know that isn't what you want to hear, but IMHO, I think that's the best course of action.

this is what i was trying to explain about cutting some slits in the ribs to direct water to the pump... also thought maybe one of the higher end intake grates with the scoop on it may help keep the pump loaded?

A top loader grate. Instead of having numerous longitudinal tines, most top loaders have 2 scoops on them, and they are supported by one massive tine on either side.

I ran a top loader on the Aluma-Jet for a while, but the problem with it, is when you operate in areas where there are weeds, etc. As it doesn't have a 'grate' so to speak, it becomes an even bigger vacuum cleaner, sucking up everything in its path.

When I designed the weedless grate on my boat, I really wanted to keep the top loader grate, but it was logistically and mechanically impossible to have a top loader grate AND a conventional grate with longitudinal tines operated by a push pull cable on a pivot..... so I had to choose between being able to operate in heavier chop without cavitation and not having a way to clear a fouled intake grate, or being able to clear my grate, but being more limited to operating at slower speeds in chop. In the end, I went with my weedless grate.

One other thought I had was that the sharp "V" in the hull ahead of the intake COULD be causing some turbulence, but before you try to modify that part of the hull, I would suspect that step between the pump and the hull.