onthewater102

Well-known member

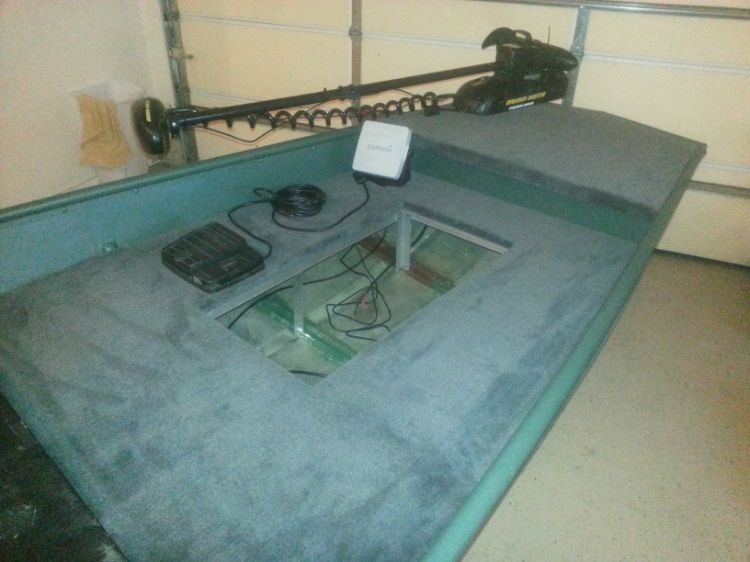

Yeah, thanx to the Mrs. I have to sell "Toys" (ie my other hobby stuff) that I'm no longer using in order to come up with the $$$ to play around with this boat as I haven't sold the Tracker Tournament 1800TF bass boat that I was supposed to in order to get the $$$ to do this.