I picked this boat up to fish horsepower restricted lakes. It came with plastic board decking and wood bracing that weighed a ton, so wanted to lighten it up, add a livewell and level out the floor. I also wanted to clean it up, add some carpeting and set it up as a tournament boat.

I started my project by gutting the boat.

I had my local PPG auto paint store do a custom match on the Forest Green Tracker paint. Sprayed the interior using a HVLP paint gun and it was a spot on match.

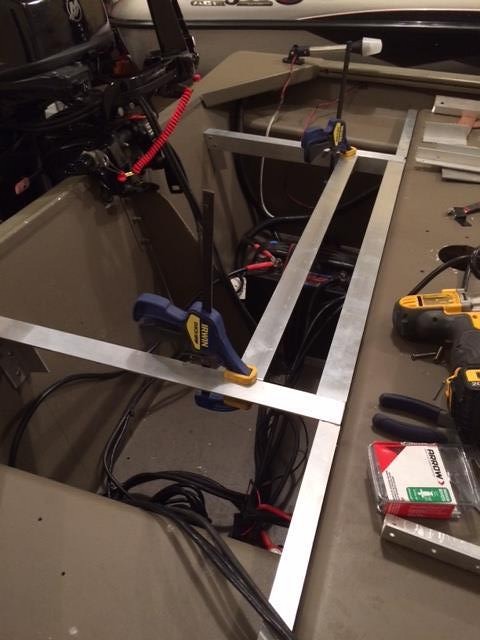

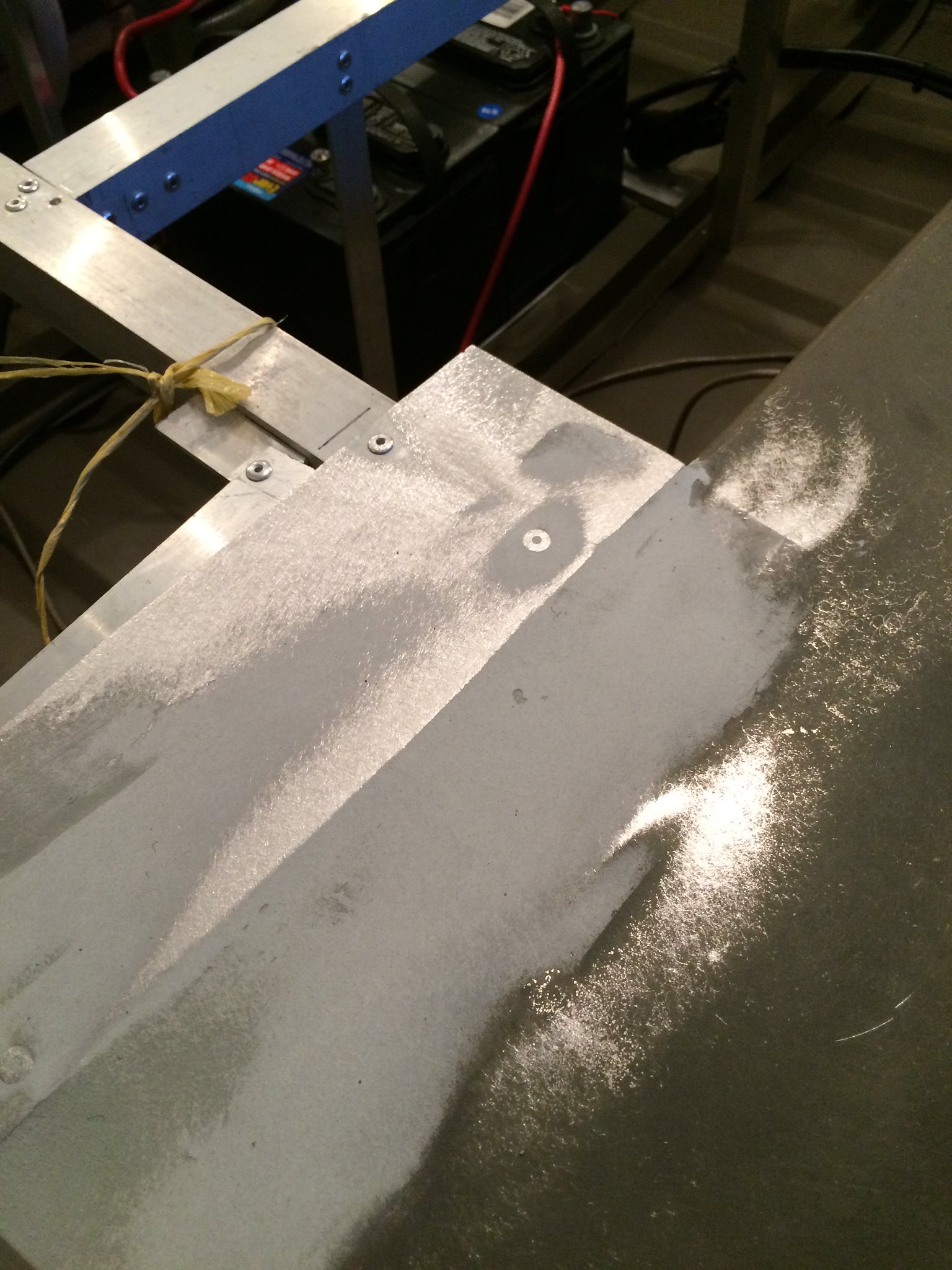

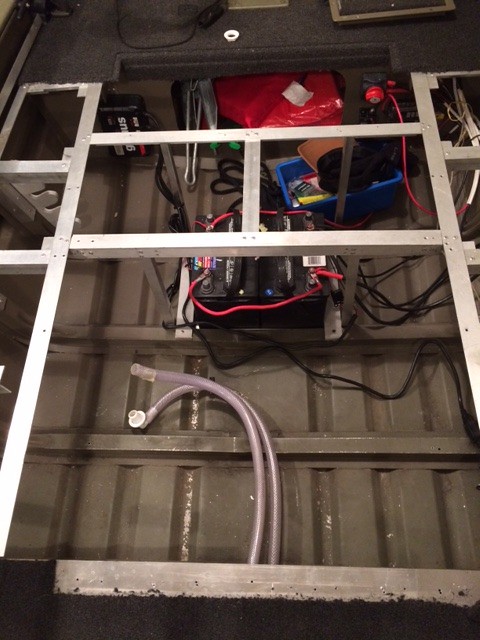

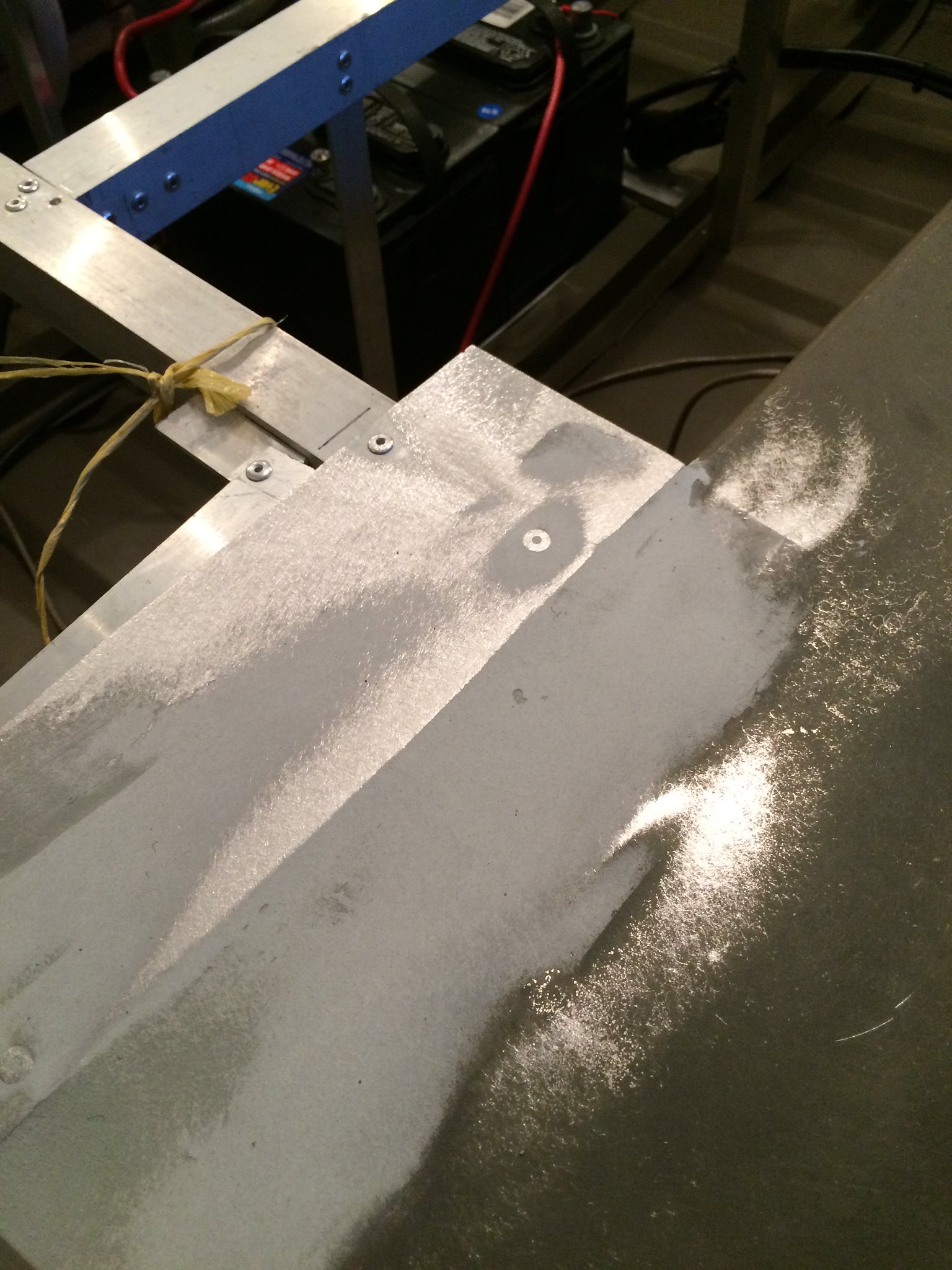

I lost the pics of the bracing, but leveled the floor using 1 1/2" aluminum angle riveted to the floor ribs and covered it with 1/8" thick 5050 aluminum.

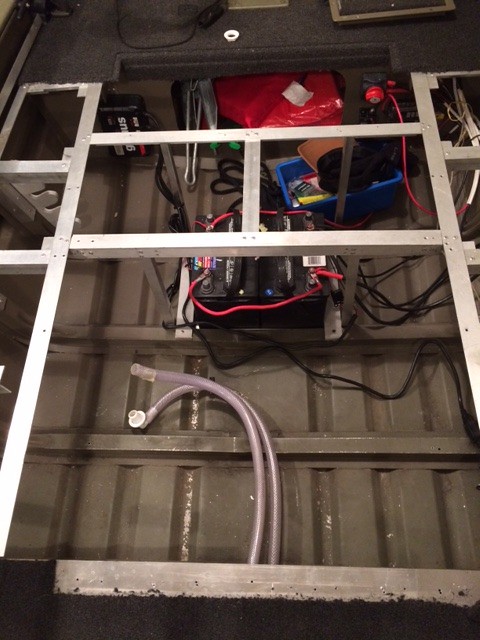

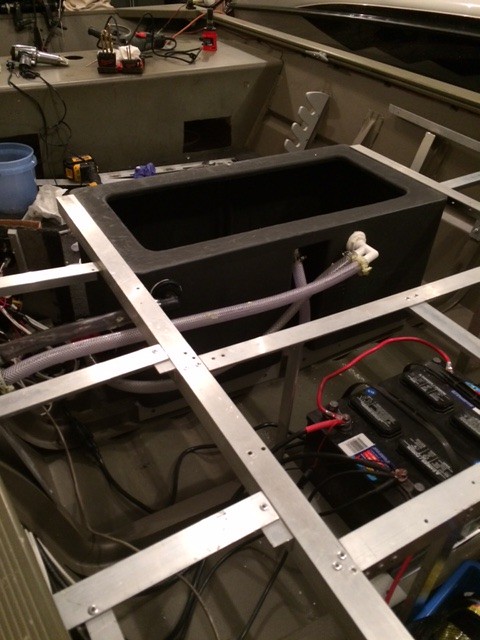

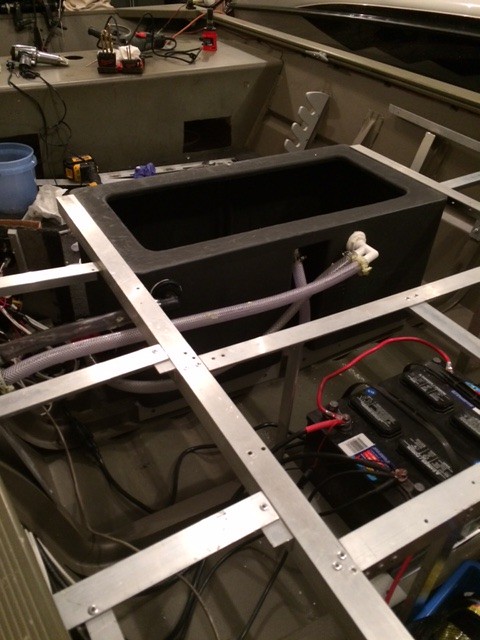

The frame was built with 3/4" and 1 1/2" aluminum angle and fastened together with aluminum rivets. I ran two lines from the back of the boat to the livewell under the floor. One for the fill pump and the second for the drain. It wasn't easy drilling the hole for the lines through the rear bench. I ended up putting two drill extension bits together so I could drill the hole.

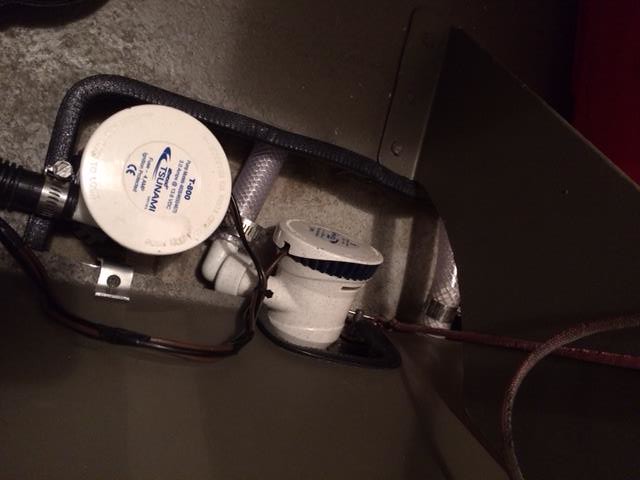

Since I planned to use the boat for tournaments, I wanted a solid livewell system. I installed the re-circulation pump on the side of the livewell so it was easy to access for cleaning and maintenance. I drilled a 1 1/4" hole right out of the side of the side of the boat for an overflow and added a Flo-Rite recirc/pump out valve, timer and LED lights inside the livewell. Originally mounted the batteries up front, but that caused some issues that I'll get into later in the post.

The flotation foam under the rear bench was completely water logged. The holes you see were used to remove the saturated foam, which must have weighed 150 pounds. The foam is suppose to be closed cell and not hold water, but this seems to be a common problem on these Trackers.

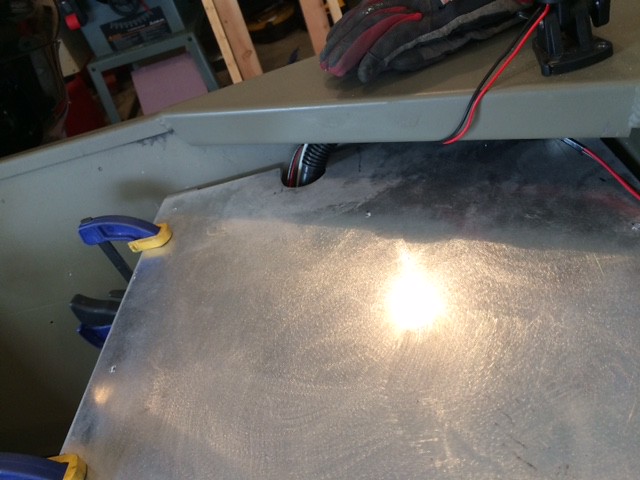

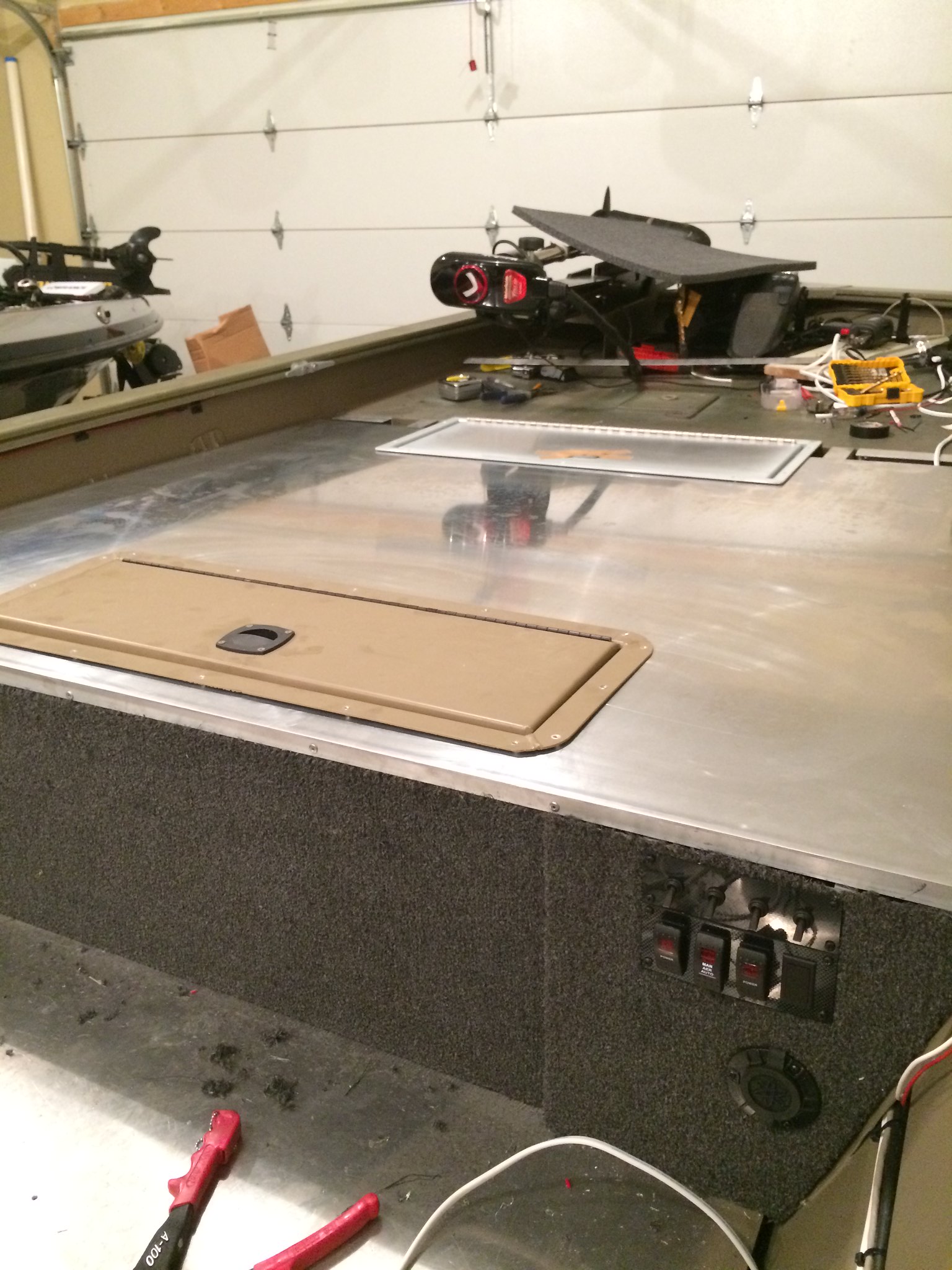

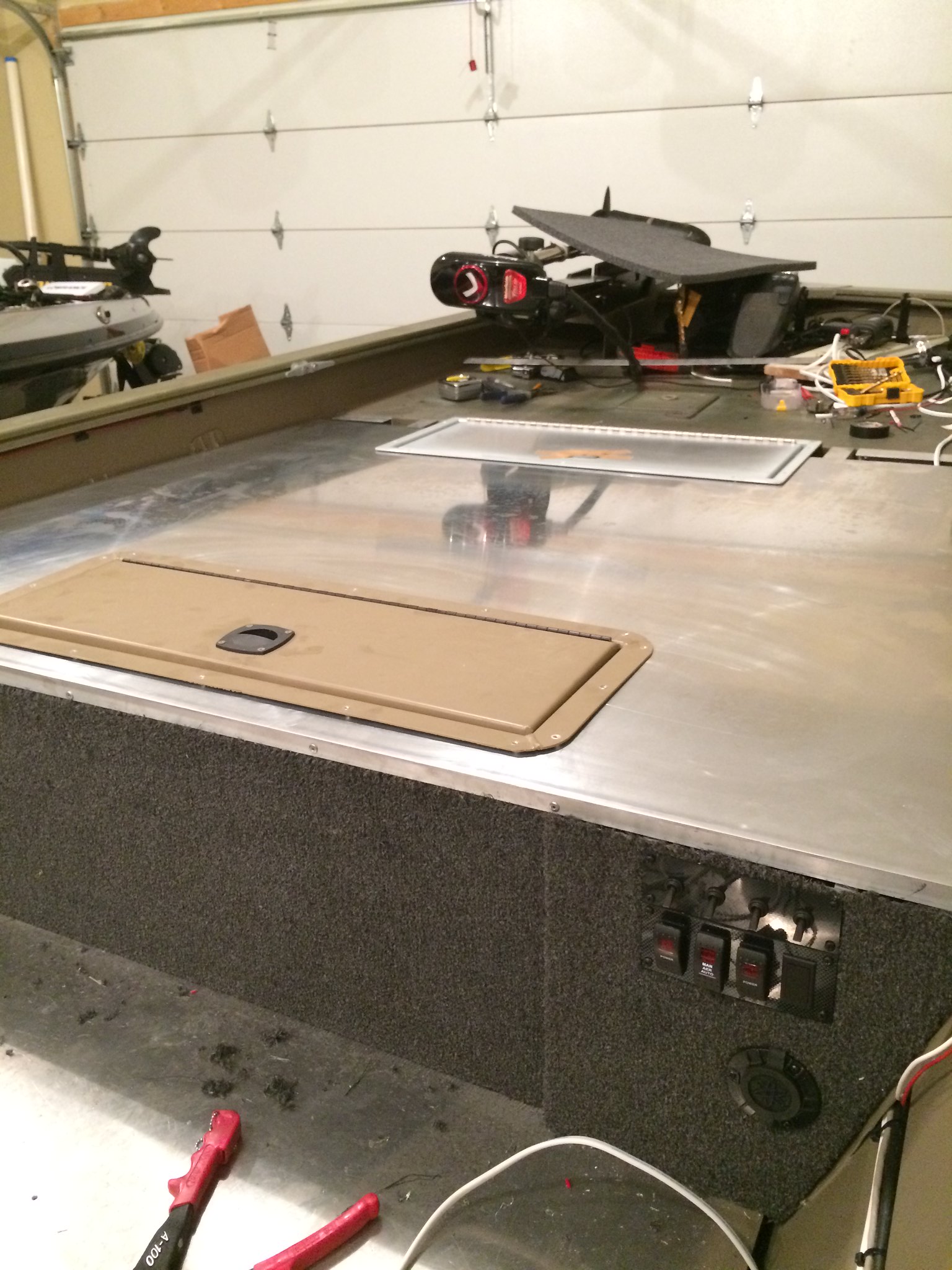

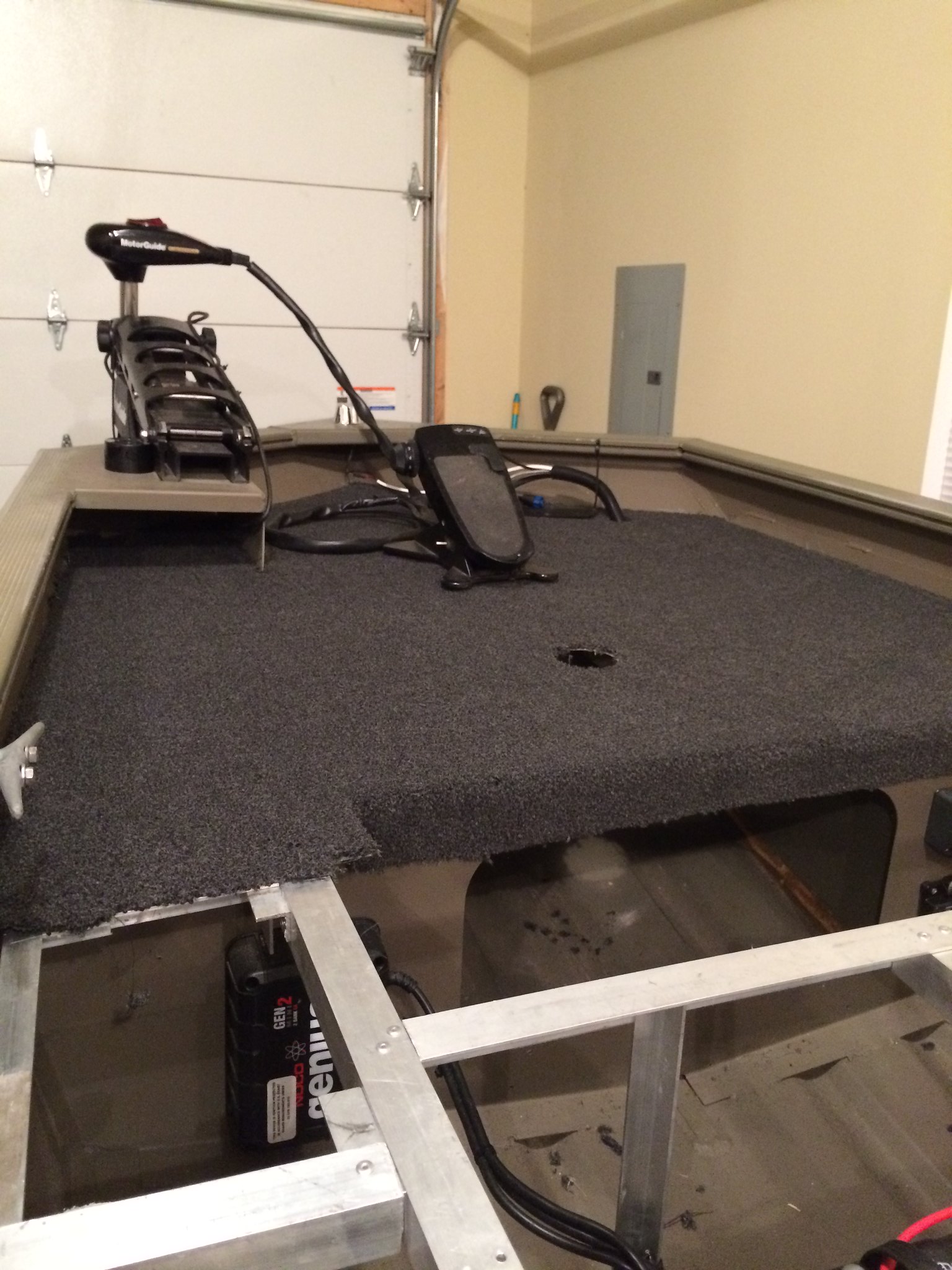

Dry fitted the aluminum deck and lids. Since the top of the boat was wider than 4', I turned the sheet so I had a nice tight fit on the sides.

I used a small piece of the old deck to make a side mount rod holder.

Closed the gap by piecing in some scraps.

I may have gone overboard, but didn't want to feel any seems, so filled them with fiberglass.

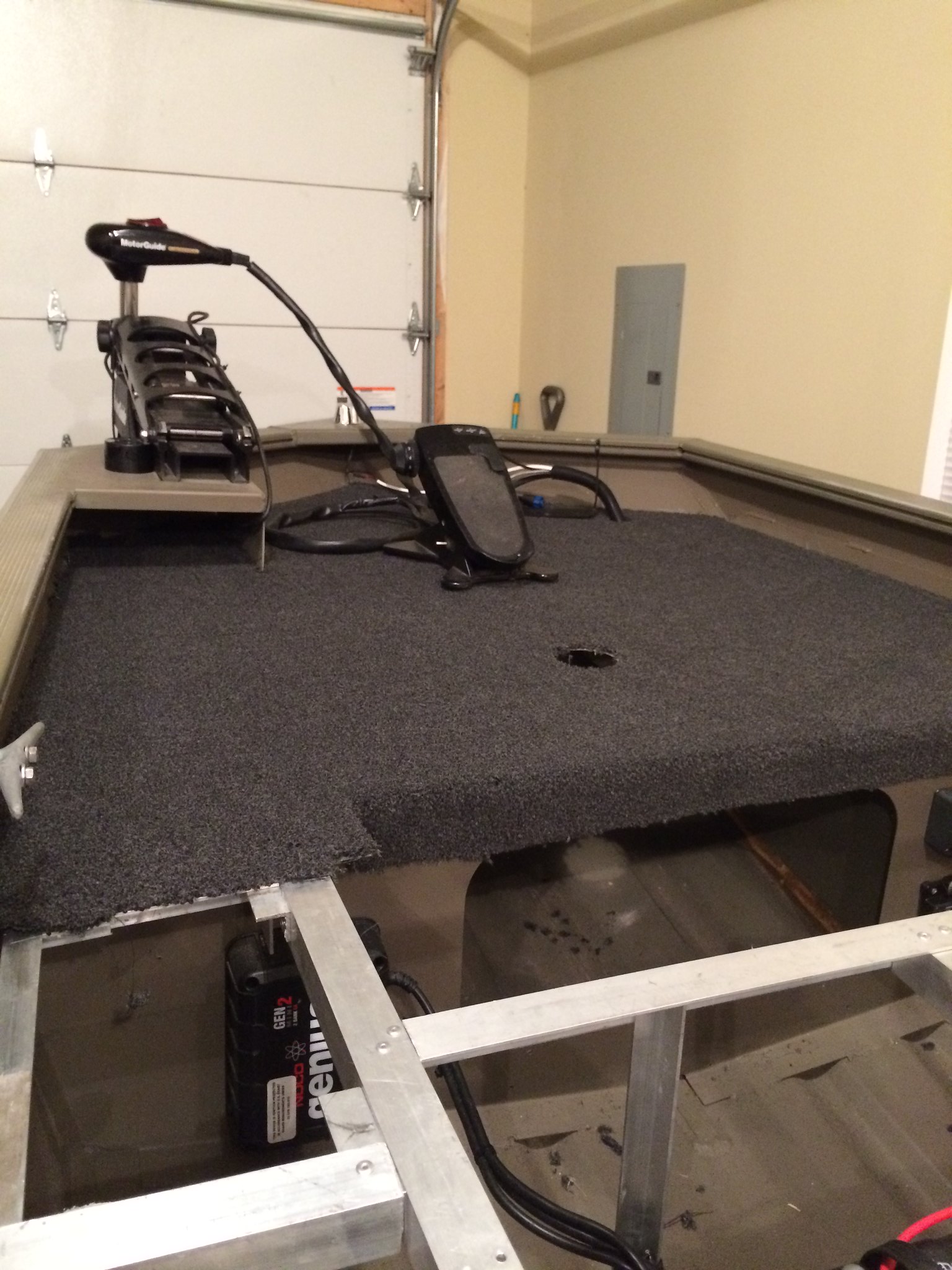

Once the carpet was down, you couldn't find the seems if you tried.

Marine wire was used for all of the electric runs. Main power is controlled by a master cut-off switch that feeds a Blue Sea sub panel for all of the accessories. I added a 24v trolling motor with 82 lbs of thrust. It has it's own breaker switch.

Mounted an Lowrance HDS7 Touch Screen on the back of the boat and have it networked with my HDS12 on the front that I plan to switch between my other boat. Networking allows me to share waypoints and a single map chip.

Structure Scan transducer and sonar.

Well that's about where I am at. I still need to build a cover for the rear hatch. If anyone has any good plans for that, I'd love to see them.

I started my project by gutting the boat.

I had my local PPG auto paint store do a custom match on the Forest Green Tracker paint. Sprayed the interior using a HVLP paint gun and it was a spot on match.

I lost the pics of the bracing, but leveled the floor using 1 1/2" aluminum angle riveted to the floor ribs and covered it with 1/8" thick 5050 aluminum.

The frame was built with 3/4" and 1 1/2" aluminum angle and fastened together with aluminum rivets. I ran two lines from the back of the boat to the livewell under the floor. One for the fill pump and the second for the drain. It wasn't easy drilling the hole for the lines through the rear bench. I ended up putting two drill extension bits together so I could drill the hole.

Since I planned to use the boat for tournaments, I wanted a solid livewell system. I installed the re-circulation pump on the side of the livewell so it was easy to access for cleaning and maintenance. I drilled a 1 1/4" hole right out of the side of the side of the boat for an overflow and added a Flo-Rite recirc/pump out valve, timer and LED lights inside the livewell. Originally mounted the batteries up front, but that caused some issues that I'll get into later in the post.

The flotation foam under the rear bench was completely water logged. The holes you see were used to remove the saturated foam, which must have weighed 150 pounds. The foam is suppose to be closed cell and not hold water, but this seems to be a common problem on these Trackers.

Dry fitted the aluminum deck and lids. Since the top of the boat was wider than 4', I turned the sheet so I had a nice tight fit on the sides.

I used a small piece of the old deck to make a side mount rod holder.

Closed the gap by piecing in some scraps.

I may have gone overboard, but didn't want to feel any seems, so filled them with fiberglass.

Once the carpet was down, you couldn't find the seems if you tried.

Marine wire was used for all of the electric runs. Main power is controlled by a master cut-off switch that feeds a Blue Sea sub panel for all of the accessories. I added a 24v trolling motor with 82 lbs of thrust. It has it's own breaker switch.

Mounted an Lowrance HDS7 Touch Screen on the back of the boat and have it networked with my HDS12 on the front that I plan to switch between my other boat. Networking allows me to share waypoints and a single map chip.

Structure Scan transducer and sonar.

Well that's about where I am at. I still need to build a cover for the rear hatch. If anyone has any good plans for that, I'd love to see them.