New River Rat

Well-known member

I'm using a trailer that could stand to be roughly two feet longer. This would help the boat transom be supported as well as keep my feet out of the water when loading. Unloading is a non-issue.

I would like a simple weld of an extension in the 20"-24" range. My concern is about the strength of the wld itself. I haven't measured the wall thickness of the trailer tongue, but it seems kinda thin.

Is there a good way to "beef" this area without looking like crap? I'd like the outside to remain smooth.

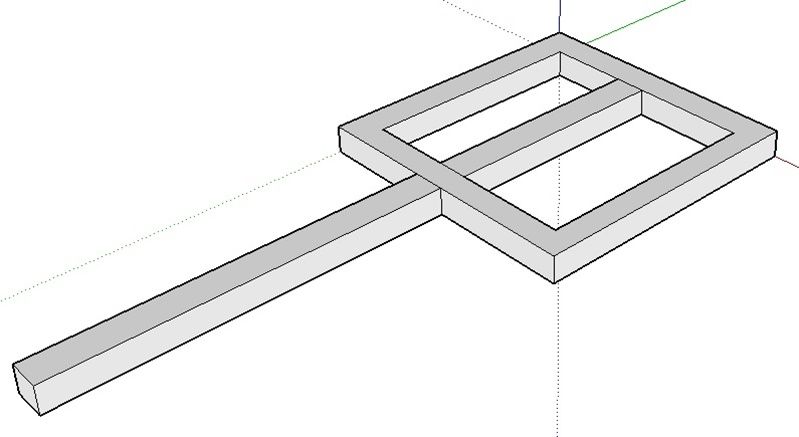

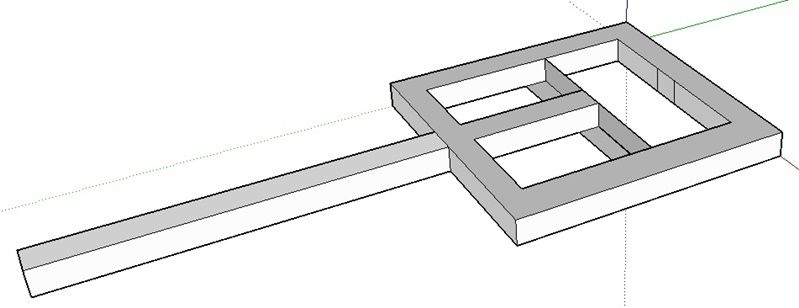

i HAVE A ROUGH IDEA OF CUTTING SYMMETRICAL NOTCHES, INSERTING ANOTHER SQUARE TUBE, AND WELDING EVERYTHING TO WORK AS ONE. aNY IMPROVEMENTS ON THIS IDEA IS WELCOME. sorry 'bout the caps.

I would like a simple weld of an extension in the 20"-24" range. My concern is about the strength of the wld itself. I haven't measured the wall thickness of the trailer tongue, but it seems kinda thin.

Is there a good way to "beef" this area without looking like crap? I'd like the outside to remain smooth.

i HAVE A ROUGH IDEA OF CUTTING SYMMETRICAL NOTCHES, INSERTING ANOTHER SQUARE TUBE, AND WELDING EVERYTHING TO WORK AS ONE. aNY IMPROVEMENTS ON THIS IDEA IS WELCOME. sorry 'bout the caps.