Well thank ya Andrew.

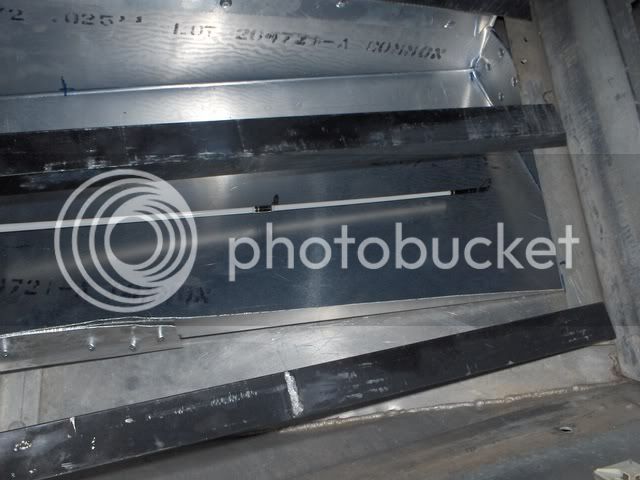

I should have another update with pictures some time soon. I have finished the bow deck structure, and have started making my measurements for the sheet. Just haven't yet had time to upload the pictures. Then comes carpet. Uggh. I don't particularly like carpet work.....

I should have another update with pictures some time soon. I have finished the bow deck structure, and have started making my measurements for the sheet. Just haven't yet had time to upload the pictures. Then comes carpet. Uggh. I don't particularly like carpet work.....