I went to the aluminum recycling place this afternoon and the closest thing I could find was a 5 foot piece of 3*5" 3/8 thick angle and a 3 footer of 5" 3/8 flat so that is what I'm building it out of. Cost was $48. 1/4 the price of a hd jack plate.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

flatbotm's 1542 build

- Thread starter Flatbotm

- Start date

Help Support TinBoats.net:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

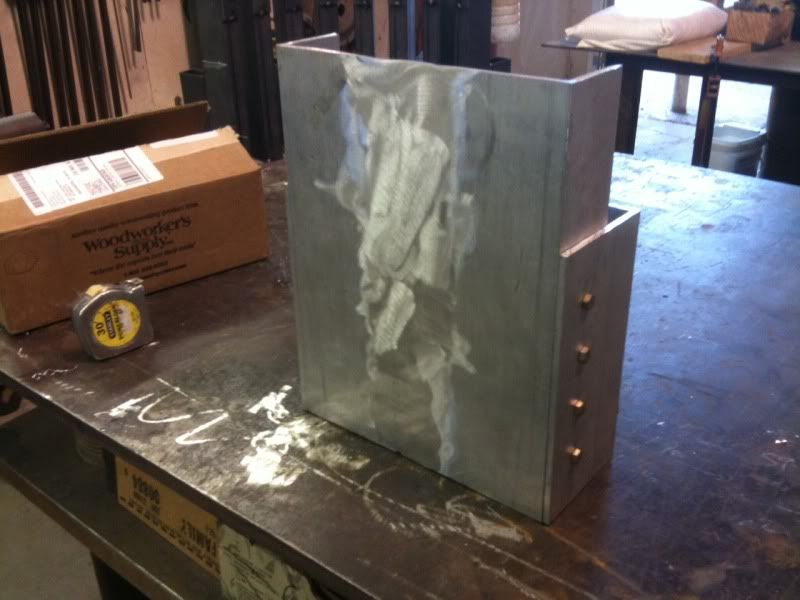

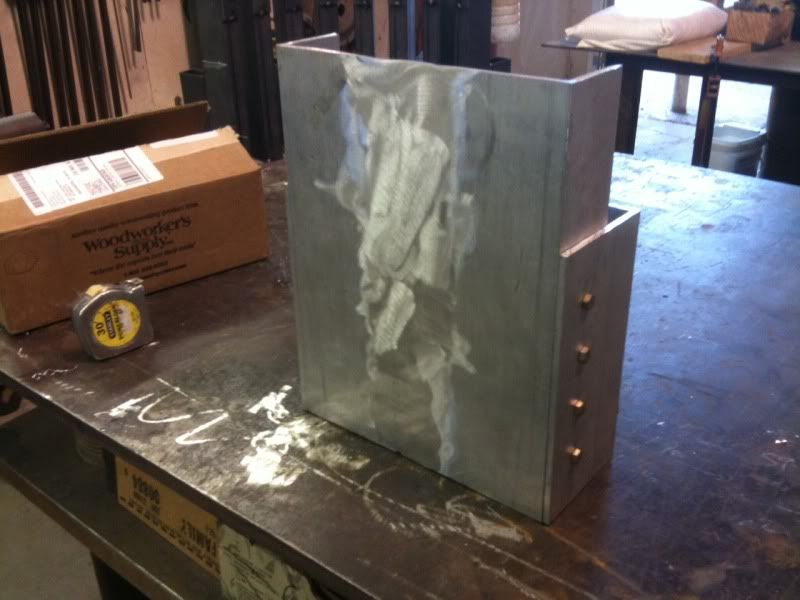

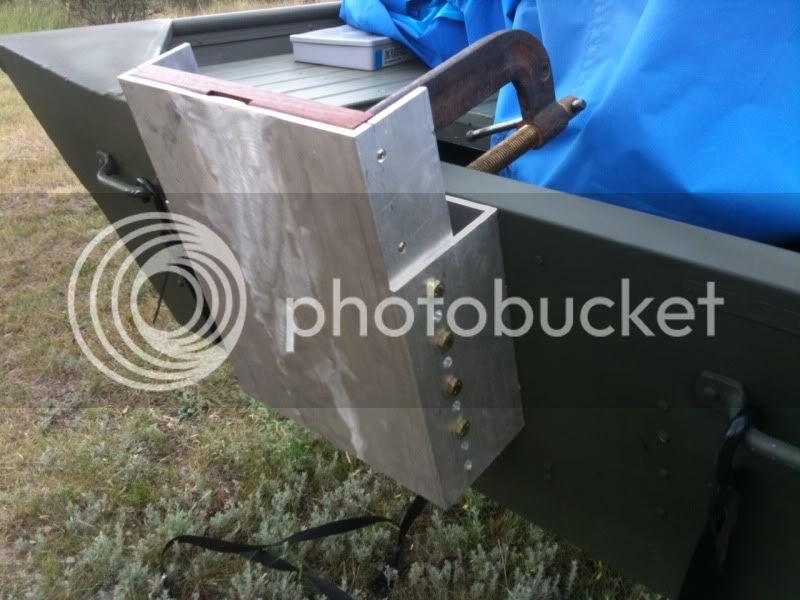

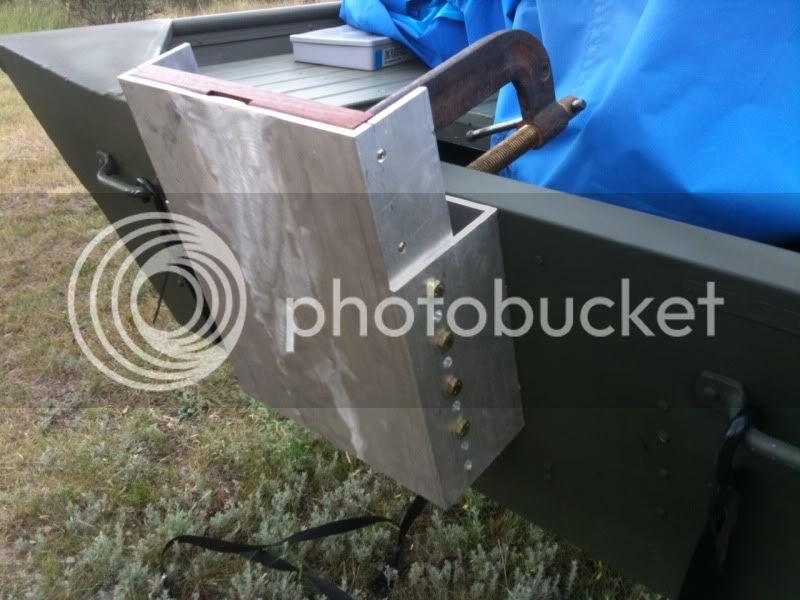

So I was wrong the angle was 1/4 and the flat stock was 3/8 woops! Oh well I Improvised. Here are the pics of the jack plate thus far. Its 5 inches of stand off and Initially it will have 5 inches of vertical rise but will be adjustable.

Derek

Well-known member

that looks great

How do you plan to make it adjustable? Are you going to slot the holes or just stagger them.

How do you plan to make it adjustable? Are you going to slot the holes or just stagger them.

Derek

Well-known member

The finite adjustment is the reason to slot them. Most people adjust them in increments of 1/2" anyway, so you should be fine with that spacing.

$60.74

Seachoice Sterling Series Boat Cover, Water Resistant, 14-18 Ft., Fish and Ski Boat

Autoplicity ✅

$19.00 ($0.59 / Fl Oz)

$24.17 ($0.76 / Fl Oz)

STAR BRITE Instant Hull Cleaner - 32 Oz Gel Spray - Easily Remove Stains, Scum Lines & Grime on Boat Hulls, Fiberglass, Plastic & Painted Surfaces - Easy to Use Formula (096132)

Amazon.com

$21.89 ($21.89 / Count)

$26.88 ($26.88 / Count)

First-Aid-Kit-for-Car-Home-Travel-Camping-Businesses, 263pcs Compact Waterproof Hard Case, Public Emergency Medical Kits - Perfect for Survival, Vehicle, Boat, Sports, Hiking, Office, Dorm (PUMIER)

Pumier Medical

$104.98 ($104.98 / Count)

Ever-Ready Industries Premium Trauma First Aid Kit for Outdoors, Workplace, and Home - Exceed OSHA Guidelines and ANSI 2009 Standards - 240 Pieces - Includes Bonus Travel Kit

EVER-READY INDUSTRIES

$45.99 ($0.14 / Count)

$49.99 ($0.15 / Count)

330 Piece First Aid Kit, Premium Waterproof Compact Trauma Medical Kits for Any Emergencies, Ideal for Home, Office, Car, Travel, Outdoor, Camping, Hiking, Boating (Red)

THRIAID

$29.39

$34.59

Seachoice Cast Aluminum “S” Dock Cleat, Corrosion Resistant Aluminum, 12 In.

Amazon.com

Cool I'll just go with the 1/2 spacing then. For the initial run how high should I jack the motor. Cav plate even or 1/2 inch up? Also what size bolts and how many for bolting to the transom? Any Special silicone?

mmf

Well-known member

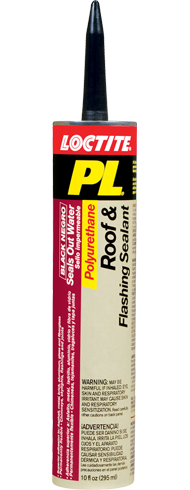

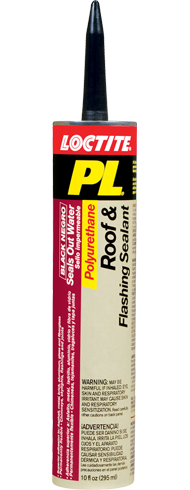

Flatbotm, this is the best sealant I have ever used on transom fasteners and on any thing to seal out water, it is polyurethane and it turns to a tough rubber like compund when dry (takes about 3 days to fully cure). Warning, wear gloves or you will have to wear it off of your hands!

mmf

Well-known member

Are you meaning the jack plate? If so, 4 might get it but I would use 6 to be on the safe side......PS, on that Loctite PL adhesive, make sure it is the "roof and flashing" sealer.....good luck and watchin your build..... 8)Flatbotm said:Thanks MMF! I'm going to go pick up some locktite. Do you guys think (4) 1/2 bolts would be enough to hold the transom to the boat?

What I meant to ask was do you think (4) 1/2 bolts will be enough to hold the jackplate to the transom? Sometimes I post with my phone and it is easy to make typos. I want to make as few holes as possible in the transom.

mmf

Well-known member

probably so, my 150 HP Mercury only has 4 SS- 1/2" bolts holding it to the transom, as a matter of fact, all my motors have 4 SS- 1/2" bolts going thru transom.......Flatbotm said:What I meant to ask was do you think (4) 1/2 bolts will be enough to hold the jackplate to the transom? Sometimes I post with my phone and it is easy to make typos. I want to make as few holes as possible in the transom.

Derek

Well-known member

agreed, my 70 has 4 - 1/2" bolts holding it on

I was hoping 4 would be enough because I allready bought 4 and they were $4.00 each. My local true value didn't have the right locktite stuff so I'm going to try home depot today.

I used my little bending break to make a bracket for the controls yesterday.

I used my little bending break to make a bracket for the controls yesterday.

Tonight I finished drilling all the holes in the jack plate. I picked up the locktite pl stuff. Do you guys with homemade jack plates mount a piece of wood where the motor clamps? I will be drilling the transom and mounting the jack plate in the morning and I was wondering if I should mount some wood or sandwich some wood in aluminum like the transom?

So I didn't get completely done this weekend as planned but I did completely finish the jackplate and it is in place and ready to drill and mount. I used a piece of Brazilian walnut for the motor mount clamps ( i am going to bolt it as well). I used some linseed oil to treat the wood. I counter sunk the stainless screws holding the (ipe) Brazilian walnut to the jack plate. I have stainless 3/8 bolts for the jack plate as well as 1/2 stainless to bolt it to the transom. Here's the pics.

Derek

Well-known member

Looks great

I am getting ready to hang the new motor and Im trying to decide where to set the jack plate up for the first run. Setting it at 5 inches of raise the bottom of the drain plug is right at 20". The bottom of the rest of the boat is 19.25 or so. I know the cavitation plate should be even with the bottom of the boat but is that refering to the lowest point? Here is the bottom of the boat so you can see what Im asking.

mmf

Well-known member

flatbotm, it's the flat part of the boat, don't count the tube....PS, if you experiment with motor height for better speed, don't get too high and starve the water pump from water without a low water pickup, it will make fast history of your motor!

Similar threads

- Replies

- 47

- Views

- 8K

- Replies

- 12

- Views

- 3K

- Replies

- 0

- Views

- 1K

- Replies

- 29

- Views

- 4K