bonz_d

Well-known member

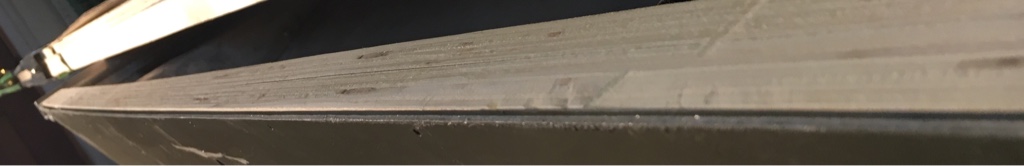

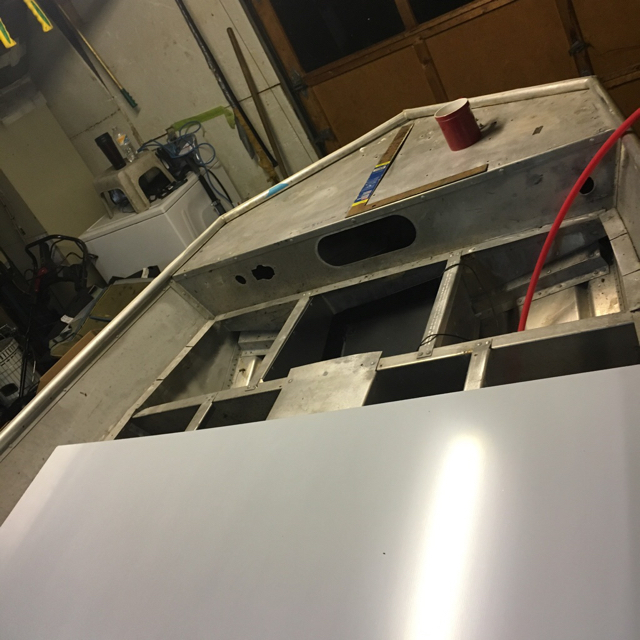

I haven't run into a problem yet with the thickness. The Nymph actually has a transom that's only 1 1/4" so I had to use a sheet of 3/4" and a sheet of 1/2". Luckily I had some 1/2" for another project that I could spare and didn't have to buy another full sheet.

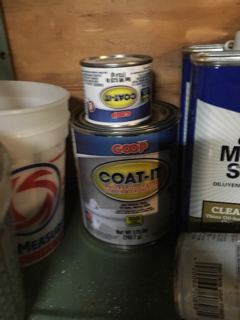

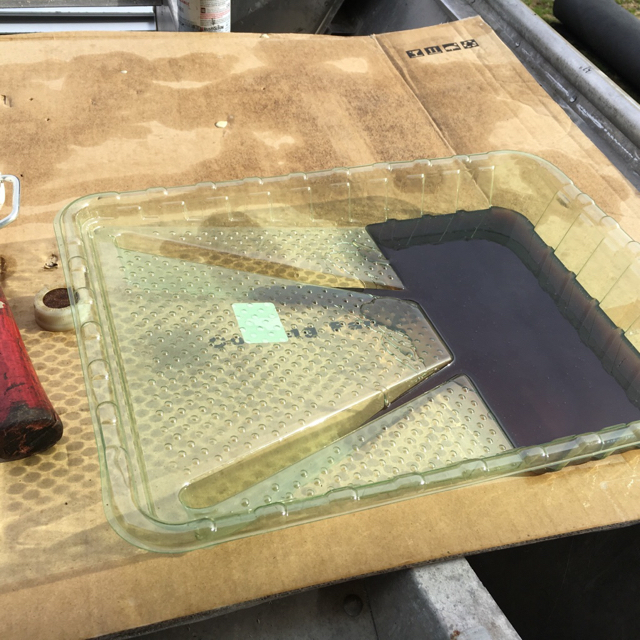

I pour the glue on liberally and then spread it with a fine notched trowel and then kind of slide the 2 pieces around on each other to bed it in before clamping. I also keep a few pieces of heavy angle that I use while clamping to help spread the force of the clamps out a little better.

I pour the glue on liberally and then spread it with a fine notched trowel and then kind of slide the 2 pieces around on each other to bed it in before clamping. I also keep a few pieces of heavy angle that I use while clamping to help spread the force of the clamps out a little better.