Alumacraft 1236 Makeover- livewell pg 11 - update front deck

- Thread starter russ010

- Start date

Help Support TinBoats.net:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

russ010

Well-known member

That pedestal takes some getting used to... the only thing I don't like is when I turn the seat around the rubber on the top of the pedestal squeaks really loud against the coils on the seat mount... but I'll get over that.

That pedestal defintely gives me more room and I can sit in a ton of different positions.. My back was not as stiff this weekend as it was before withthe previous mount I had on there.

That pedestal defintely gives me more room and I can sit in a ton of different positions.. My back was not as stiff this weekend as it was before withthe previous mount I had on there.

rcgreat

Well-known member

Russ, I have a question about your livewell, How are you securing your pump to the container? I have a cooler that I am using now with a bait saver pump and I found that I had to glue the pump down to keep it from floating up. Thanks in advance.

Gary

Gary

I have noticed the same with mine, which are the straight version that of what he has. I am going to be welding a .75 washer to the bottom of the spring to see if that will quiet it down some.russ010 said:the only thing I don't like is when I turn the seat around the rubber on the top of the pedestal squeaks really loud against the coils on the seat mount... but I'll get over that.

Next time you are in my boat, bring that pedestal, and see if you like it better for the stern deck on my rig. If so, I will see about getting one of those to keep back there instead of the straight one I currently have.

We need to get out to Lake Acworth again. Or Allatoona even. This rain has certainly done something for Allatoona, from the reports I am reading, and I am willing to bet that Acworth has benefitted from it too, possibly more than Allatoona. I would love to be able to crappie fish Weiss right now, but that doesn't look like it will happen.

baptistpreach

Well-known member

Did you finish your livewell yet??

russ010

Well-known member

rcgreat said:Russ, I have a question about your livewell, How are you securing your pump to the container? I have a cooler that I am using now with a bait saver pump and I found that I had to glue the pump down to keep it from floating up. Thanks in advance.

Gary

I haven't got that far yet... but what I plan on doing is gluing a 2" strip of velcro to the bottom, then do the same on the bottom of the pump. I've used velcro for underwater stuff before and it held up pretty well. I'll use a few dabs of 3M 5200 on the bottom side. Then I can just pull off the pump by the velcro, or I can turn it still attached and take just the pump off the bottom holder

$20.47 ($1.28 / Fl Oz)

$22.02 ($1.38 / Fl Oz)

STAR BRITE Fiberglass Color Restorer - Specially Formulated for Colored Boat Hulls - Renew, Shine & Protect -16 OZ (081816PW)

Marine Elements LLC

$29.39

$34.59

Seachoice Cast Aluminum “S” Dock Cleat, Corrosion Resistant Aluminum, 12 In.

Amazon.com

$19.00 ($0.59 / Fl Oz)

$24.17 ($0.76 / Fl Oz)

STAR BRITE Instant Hull Cleaner - 32 Oz Gel Spray - Easily Remove Stains, Scum Lines & Grime on Boat Hulls, Fiberglass, Plastic & Painted Surfaces - Easy to Use Formula (096132)

Amazon.com

russ010

Well-known member

bassboy1 said:We need to get out to Lake Acworth again. Or Allatoona even. This rain has certainly done something for Allatoona, from the reports I am reading, and I am willing to bet that Acworth has benefitted from it too, possibly more than Allatoona. I would love to be able to crappie fish Weiss right now, but that doesn't look like it will happen.

I'm free this weekend Sat - Monday... just give me a call or shoot me an email. I plan on getting out some this weekend

russ010

Well-known member

baptistpreach said:Did you finish your livewell yet??

Dude, this has been a hectic year for me already. I have worked a total of 6 days at my real job so far and I'm backed up something fierce. I worked 2.5 days last week, then left Wed night for military and that lasted til Sunday. I'm working all this week, then off this weekend and Monday, then I'm going to Nashville Tuesday and Wednesday next week for some client meetings. I'm going to try and work on it during the nights this weekend as long as my wife doesn't have something lined up for me that I don't already know about

baptistpreach

Well-known member

Umm..... Sorry I asked?! Hope it slows down or that in good time you get a chance to finish the livewell, believe me, I know there are more important things in life :roll:

russ010

Well-known member

baptistpreach said:Umm..... Sorry I asked?! Hope it slows down or that in good time you get a chance to finish the livewell, believe me, I know there are more important things in life :roll:

I'm glad work is busy - that's job security for me! I really don't have that much to do so it shouldn't be a problem getting it done. I've already got it dry fitted, just need to glue it all together and test it out

rcgreat

Well-known member

Russ, I understand what your saying about being busy I have a Ten year old and a 1 year old seems like something is always going on especially with the ten year old and girl scouts (anyone want any cookies :lol . This livewell has been driving me crazy, I just wanted to make sure I was not over analyzing it. That is a brillant idea with the velcro, the company I work for uses whats called snap tape which is like velcro on steroids and is plastic backed instead of fabric based. I think that will be perfect for the pump. Thank You again.

. This livewell has been driving me crazy, I just wanted to make sure I was not over analyzing it. That is a brillant idea with the velcro, the company I work for uses whats called snap tape which is like velcro on steroids and is plastic backed instead of fabric based. I think that will be perfect for the pump. Thank You again.

russ010

Well-known member

rcgreat said:Russ, I understand what your saying about being busy I have a Ten year old and a 1 year old seems like something is always going on especially with the ten year old and girl scouts (anyone want any cookies :lol. This livewell has been driving me crazy, I just wanted to make sure I was not over analyzing it. That is a brillant idea with the velcro, the company I work for uses whats called snap tape which is like velcro on steroids and is plastic backed instead of fabric based. I think that will be perfect for the pump. Thank You again.

those girl scout cookies sound pretty good right now....

rcgreat

Well-known member

How many boxes would you like?

clarker2000

Well-known member

Your boat looks great. In fact I just posted a subject about this exact boat. Couple of questions for you:

1. I have noticed the same problem with the trailer and winch and boat all getting in the way of each other. Im not a metal fabricator by any means but would you have any other ideas on how to eliminate this problem? Could a metal shop do this for me? Or could I make this piece out of parts from home depot? I dont understand why they would make a trailer that has that problem???

2. You removed the center seat/floatation area? Have you had any floatation problems?

3. Im curiuos about the paint? Could you elaborate on all the products used and where to get them? I was looking to use spray paint only, is that possible?

Thanks

1. I have noticed the same problem with the trailer and winch and boat all getting in the way of each other. Im not a metal fabricator by any means but would you have any other ideas on how to eliminate this problem? Could a metal shop do this for me? Or could I make this piece out of parts from home depot? I dont understand why they would make a trailer that has that problem???

2. You removed the center seat/floatation area? Have you had any floatation problems?

3. Im curiuos about the paint? Could you elaborate on all the products used and where to get them? I was looking to use spray paint only, is that possible?

Thanks

russ010

Well-known member

clarker2000 said:Your boat looks great. In fact I just posted a subject about this exact boat. Couple of questions for you:

1. I have noticed the same problem with the trailer and winch and boat all getting in the way of each other. Im not a metal fabricator by any means but would you have any other ideas on how to eliminate this problem? Could a metal shop do this for me? Or could I make this piece out of parts from home depot? I dont understand why they would make a trailer that has that problem???

2. You removed the center seat/floatation area? Have you had any floatation problems?

3. Im curiuos about the paint? Could you elaborate on all the products used and where to get them? I was looking to use spray paint only, is that possible?

Thanks

I'll answer your questions below..

1. I have come up with a way to make it better. I had my dad weld me some new parts, and I left them at his house in South Carolina (I'm in GA), but I did figure out how to fix it. I'll take pics of the part that I have and explain how to do it better later tonight.

2. The flotation foam is not for the boat to float while you're in it - it's there to keep the boat from sinking should you capsize or flip over. I don't plan on that happening because I won't be in any rough water. I've had no issues with it floating. Actually, by removing the foam you are reducing weight of the hull, and you can pick up a little more speed as well as being able to put more stuff in it. I have 4 - 60lb deep cycle batteries in there right now, plus me at 180lbs, and the current wood in there weighs maybe 75lbs. I have a trolling motor in the front, and 1 in the back - but there's about to be 2 back there. I also made a removable 22gal livewell. I had all of this in there 2 weeks ago, with the livewell full and had no problems. Don't be afraid of removing the foam!

3. I got this stuff at Boater's World, and the primer I used was on clearance, so I don't remember the actual price. But here's a rough break down of the whole process.

Preparation for Painting:

a. 2 - wire sand discs for power drill ($5 at Walmart)

b. denatured alcohol (clean boat with this after sanding to remove all dust)

c. lintless cloths (use to wipe boat down before, during and after painting)

Start with sanding the boat, you don't have to go all the way down to the metal - just make the surface smooth to the touch. Once you are finished sanding, wipe the boat down with denatured alcohol to remove all dust and paint particles.

Primer:

a. Zinc Chromate (I got this at Boater's World on clearance for $10. I'm not sure of the actual cost or brand name... but it's yellow.

b. Brush, roller, or air compressed paint sprayer (whatever your preference is)

c. automotive paint thinner (O'Reillys has this for about $10 per bottle)

d. Paint ratio mixer - (O'Reillys, just a plastic cup that gives you the right ratio for mixing the thinner and paint)

e. 220 grit sandpaper - for sanding between coats

I used a brush to put the primer on. It was thick as molasses... I messed up by not thinning it out. 1 quart gave me 1 thick covering, so I was ok. I would recommend thinning it out and putting atleast 2 coats on. After the first coat, you can wetsand the overruns or blemishes with the 220grit paper. Just sand it down to where it is smooth and inline with the rest of the primer. Always remember that your outer paint job will only look as good as the coats underneath!

Paint

a. Pettit EasyPoxy Polyurethane - 1 quart gave me 3 thin coats on a 1236 jonboat

b. Brush, roller, or air compressed paint sprayer (whatever your preference is)

c. automotive paint thinner (O'Reillys has this for about $10 per bottle)

d. Paint ratio mixer - (O'Reillys, just a plastic cup that gives you the right ratio for mixing the thinner and paint)

e. 220 grit sandpaper - for sanding between coats

I painted 3 light coats, wetsanding between each coat to take out any blemishes or runs.

I used a paint spray gun I bought at Home Depot some time ago to paint with. I think it cost me like $70 when I bought it, so I don't know current prices on it now. I would suggest getting a Gravity Fed paint sprayer like this one (CLICK HERE. This is the exact one I have, and it worked great. One coat per can full. Just make sure you do the ratio right (the guys at O'Reillys or wherever you get your paint from and tell you the mixing amounts, I think I actually posted it in this thread somewhere, but I don't remember it off the top of my head). Overlap the sprays a little, and make sure to stay away from the boat atleast 6-8" per stroke, otherwise you'll have some vicious runs to sand out. Wait atleast 24 hours between painting, allowing each coat to cure.

If you have any more questions, let me know - I'll help out anyway I can. Good luck and post lots of pics of your mod!

clarker2000

Well-known member

Thanks for the help Russ. I appreciate it!! =D> I have a 17 ft grizzly that is decked with a 60 volt electric motor on the back. Its one giant deck from front to back with tons of storage. I will post some pics. I can get it to about 8mph with 2 people and a full load. Im working on getting a newly designed german battery that is a 24 volt battery but it lasts a ton longer then regular deep cycles and its half the weight. It turned out very nicely if I may say so.

I am building the same boat you have for my buddy. Im going to slightly alter what you have done but keep the same general concept. We are trying to keep weight to a minimum only because of using electric only power. If you could get me more details on the front winch/block thing that would be awesome. I noticed one guy that had the winch on the bottom and the block above it. Very different but it works I guess? Still dont understand what he guy was thinking when he designed that? This boat will have a 24 volt motorguide up front and a 36 volt 109 Minnkota in the back with 2 depth finders. My main idea is to have one big deck with 2 pedestal seats and tons of storage. Keeping ths in mind I would be adding in a Torqueedo electric motor next year and getting rid of the 109. The torqueedo is pretty cool. 24 volts 165 lbs thrust and runs on those light german batteries. I think it would really move that boat along well.

I am building the same boat you have for my buddy. Im going to slightly alter what you have done but keep the same general concept. We are trying to keep weight to a minimum only because of using electric only power. If you could get me more details on the front winch/block thing that would be awesome. I noticed one guy that had the winch on the bottom and the block above it. Very different but it works I guess? Still dont understand what he guy was thinking when he designed that? This boat will have a 24 volt motorguide up front and a 36 volt 109 Minnkota in the back with 2 depth finders. My main idea is to have one big deck with 2 pedestal seats and tons of storage. Keeping ths in mind I would be adding in a Torqueedo electric motor next year and getting rid of the 109. The torqueedo is pretty cool. 24 volts 165 lbs thrust and runs on those light german batteries. I think it would really move that boat along well.

Safety.clarker2000 said:I noticed one guy that had the winch on the bottom and the block above it. Very different but it works I guess? Still dont understand what he guy was thinking when he designed that?

That is what he was thinking. You see, if the winch fails, and you hit the brakes, your boat is going to try real hard to end up in the back of your tow vehicle. If the block is above the bow eye/winch, there is a better chance of the bow eye getting hung up on it, and you will not find the bow of the boat breathing down on your neck.

clarker2000

Well-known member

Bassboy

Maybe my post came across wrong but I was not referring to the guy that posted on the site with the winch below the roller. I was referring to the guy who made my personal trailer. That was what the last several posts were about. The design for my trailer and russ' trailer is all f-ed up. You cant crank the winch because you end up hitting the boat on every crank. I actually like the post on this site with the winch below the roller, it solves my problem with no extra $$$$. Sorry for any confusion.

Maybe my post came across wrong but I was not referring to the guy that posted on the site with the winch below the roller. I was referring to the guy who made my personal trailer. That was what the last several posts were about. The design for my trailer and russ' trailer is all f-ed up. You cant crank the winch because you end up hitting the boat on every crank. I actually like the post on this site with the winch below the roller, it solves my problem with no extra $$$$. Sorry for any confusion.

russ010

Well-known member

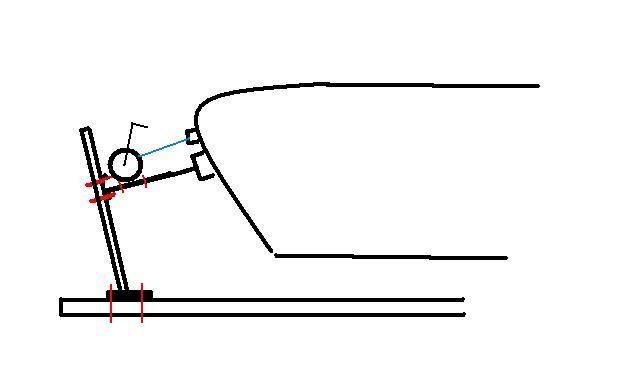

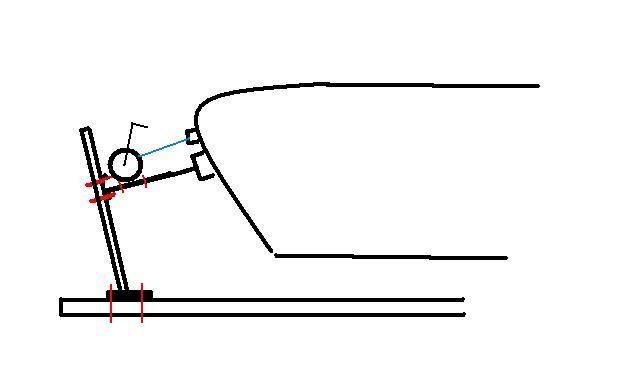

I wasn't able to get pics... my camera batteries died, but they are on charge and I'll get some. If I could figure out how to draw better I would... but this gets the idea across.

Basically I welded 2" plates to the end of the main piece which is 2" steel square tube, I don't know what angle that is - that's the piece I left in SC. It attached to the trailer with 2 U-Bolts - this allows me to move it back and forth on the trailer.

The piece that has the winch on it, I think it's 18" long, but I'm not certain. It's also steel and it's 1/4" thich by 2" wide. I can drill 2 holes into it and bold the winch directly to that. On the end there is thin pieces of sheet metal formed in the shape of a U. I drilled a hole through the center of each side and inside rests one of those bow stops like you get at BPS for Vee boats. This I have, but don't have a pic of yet. I rounded out the corners of the U so that the black rubber stop will swivel just a little bit to lay flat against the boat. This attached to the main tube by a 2" wide piece of metal that is welded - similar to the bottom that attaches to the trailer beam. It also attaches with U-bolts so that I can slide it up and down the tube for the best fit.

Once I can take some pictures, this should make more sense... but I think it should work well once I get it all put together.

Basically I welded 2" plates to the end of the main piece which is 2" steel square tube, I don't know what angle that is - that's the piece I left in SC. It attached to the trailer with 2 U-Bolts - this allows me to move it back and forth on the trailer.

The piece that has the winch on it, I think it's 18" long, but I'm not certain. It's also steel and it's 1/4" thich by 2" wide. I can drill 2 holes into it and bold the winch directly to that. On the end there is thin pieces of sheet metal formed in the shape of a U. I drilled a hole through the center of each side and inside rests one of those bow stops like you get at BPS for Vee boats. This I have, but don't have a pic of yet. I rounded out the corners of the U so that the black rubber stop will swivel just a little bit to lay flat against the boat. This attached to the main tube by a 2" wide piece of metal that is welded - similar to the bottom that attaches to the trailer beam. It also attaches with U-bolts so that I can slide it up and down the tube for the best fit.

Once I can take some pictures, this should make more sense... but I think it should work well once I get it all put together.

Oh, that is what I get for opening my big mouth without reading all the posts (I skimmed if that counts for something :wink: ).clarker2000 said:Bassboy

Maybe my post came across wrong but I was not referring to the guy that posted on the site with the winch below the roller.

Open mouth... Insert foot..... #-o #-o

Similar threads

- Replies

- 7

- Views

- 708

- Replies

- 2

- Views

- 454

- Replies

- 34

- Views

- 4K

- Replies

- 27

- Views

- 7K